Transmission Chains

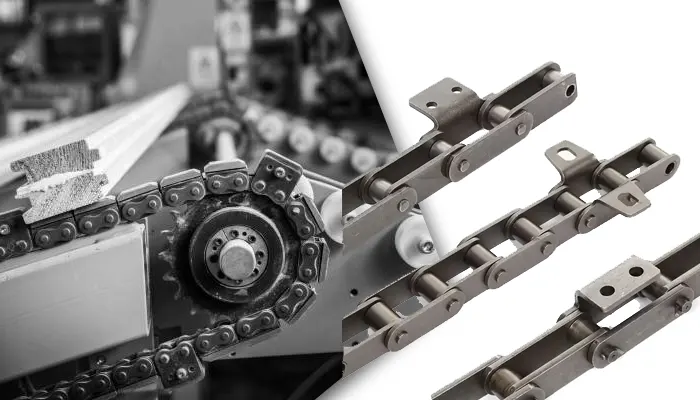

Conveyor Chains

Conveyor Chains

- FV Type Conveyor Chain

- FV Type Conveyor Chain Attachments

- FV Type Hollow Pin Conveyor Chain

- FV Type Scraper Conveyor Chain

- FVT Type Conveyor Chain

- FVC Type Hollow Pin Conveyor Chains

- M Type Conveyor Chain

- M Type Conveyor Chain Attachments

- M Type Hollow Pin Conveyor Chain

- M Type Scraper Conveyor Chain

- Z Type Conveyor Chains

- ZE Type Conveyor Chains

- Z Type Conveyor Chain with Attachments

- ZC Type Conveyor Chains

- YS Type Conveyor Chain

- YS Type Hollow Pin Conveyor Chain

- Heavy Duty Cranked Link Transmission Chain

- Double Flex Chains

Conveyor Chain for Metallurgy and Steel Industry

- Leaf Pin Chains

- Conveyor Chain of Steel Sheet

- Lift Chain for Steel Lngot

- Billet Conveyor Chain

- Cold Bed Chain

- Chain-Style Roll Conveyor Chains

- Air-drying Chains

- Painted Chains

- Painting Drying Chain

- Furnace Tube Flaw Detection Chain

- Traverse Chain

- Loading Chains for Metallurgical

- Large-Pitch Heavy Duty Loading Chains

- Side Chain

- Press-threaded Chain

- Fast Chains

- Hoist Chain

Conveyor Chains for Automobile Manufacturing

- Conveyor Chains for Automobile Spray Painting Line

- Loading Chain for Automobile Manufacture (Skid Chain)

- Conveyor Chains for Automobile Showering Line (Stainless Steel)

Conveyor Chains for Grain and Oil Industry

- Welded Cranked-Link Mill Chains

- Welded Cranked-Link Mill Chain Attachments

- Forging Chains

- Forging Chain Attachments

- M Series Conveyor Chains

- M Series Conveyor Scraper Chain Attachments

- FV Series Conveyor Chains

- FV Series Conveyor Scraper Chain Attachments

Conveyor Chain for Cement Mill Industry

- Attachment Sidebar Elevator Chains

- Bucket Elevator Chains

- FU Style Chains

Transmission Roller Chains

- A Series Single-Strand Roller Chain and Bushing Chain

- A Series Double-Strand Roller Chain and Bushing Chain

- A Series Triple-Strand Roller Chain and Bushing Chain

- B Series Single-Strand Roller Chain

- B Series Double-Strand Roller Chain

- B Series Triple-Strand Roller Chain

- A Series Straight Plate Roller Chain

- B Series Straight Plate Roller Chain

- Short-Pitch Heavy-Duty Series Roller Chain

- Short-Pitch Precision Roller Chain Attachments

- Side Bow Chain

- Double Pitch Transmission Roller Chain

- Double Pitch Conveyor Roller Chain

- Double Pitch Conveyor Chain Attachments

- Double Pitch Conveyor Chain with Extended Pins

Agricultural Chains

- Combine Standard Chain

- Tractor Chain & Ratovator Chain

- Hoist Chain

- Rice Harvester Chains

- CA Type Steel Agricultural Roller Chain

- S, A Type Steel Agricultural Roller Chain and Attachments

- C Type Steel Agricultural Roller Chain

- Agricultural Roller Chain Attachments

Engineering Chains

- Heavy-Duty Cranked-Link Chains

- Hollow Pin Conveyor Chains

- Trencher Chains

- Conveyor Chains for Glove Industry

- Block Chains

Sugar Mill Chains

- Sugar Mill Chains with Straight Plate

- Sugar Mill Chains with Bent Plate

- Other Type of Sugar Mill Chains

- Attachments of Sugar Mill Chains

Palm Oil Chains

- Palm Oil Chains with Straight Plate

- Palm Oil Chains with Bent Plate

Special Chains

- “O” Ring Chain

- Hollow Pin Chains

- Double Plus Chain

- Speed Conveyor Chain

- Single Side Roller Attachment Chain

- Double Sides Roller Attachment Chain

- Steel Pintle Chain

- Roller Chain Attachments with Elastomer Profiles

- Rubber Conveyor Chain

- Sharp Top Chain

- Lumber Conveyor Chain & Attachments

- 3939 Lumber Conveyor Chain & Attachments

- Steel Detachable Chain

- Steel Welded Type Cranked Link Chain

- Heavy Duty Cranked Link Transmission Chain

- Engineering Steel Bushing Chains

- Engineering Steel Bushing Chain Attachments

- Conveyor Chains for Steel Mill

Stainless Steel Roller Chains

Malleable Cast Iron Chains

- 400 Class Pintle Chains

- 500 Class Bucket Elevator Chains

- 600 Class Ley Bushed Chains

- 700 Class Wastewater Chains

- 900 Class Sugar Mill Chains

- Casting Detachable Chains

- Boiler Moving Grate Chains

- CC Class Conveyor Chains

- Combination Chains

- Combination Transfer Chains

- DIN654 Class Pintle Chains

- Drop Forged Conveyor Chain

- H Class Mill Chains

- H Class Refuse Drag Chains

- H Transfer Rooftop Chains

- Welded Steel Mill Chains

- MC33 Double Flex Chain

Leaf Chains

- Leaf Chain (LH-BL Series)

- Leaf Chain (LL Series)

- Leaf Chain (AL Series)

- Leat Chain for Sky Stacker

- Car Parking Chains

How to Choose a Chain and Drive System Suitable for Industrial Applications?

In the field of modern industrial automation and mechanical transmission, choosing the appropriate chain and drive system is crucial for the stable operation of equipment and production efficiency. Whether in heavy machinery, conveying systems, or agricultural equipment, chains and drives play a key role in connecting power and efficiency.

Clarify Application Requirements

To select the appropriate chain and drive system, it is necessary to clarify its application scenarios first. The requirements for the transmission system vary under different working conditions, for example:

Heavy-duty transmission: chains and drives with high strength and wear resistance are required;

HHeavy-duty transmission: Emphasizing precision and stability, with a requirement for small chain clearance;

Special environments: In high-temperature, humid or corrosive environments, chains and drives made of special materials need to be selected.

Pay Attention to Material and Structural Design

The high-quality chain and drive system is made of high-strength alloy steel or stainless steel and is capable of coping with various harsh environments. Meanwhile, the structural design of the chain (such as roller chains, plate chains, etc.) also directly affects its load-bearing capacity and service life.

Ensuring that the selected products comply with international standards such as ISO and ANSI is the foundation for guaranteeing the stable operation of the equipment.

Cost and Cost-effectiveness Considerations

Although the high-end chain and drive system has a higher cost, in the long run, its higher durability and lower maintenance frequency can effectively reduce the overall operating cost.

Brand and After-sales Service

Choosing the chains and drives brand with a good reputation in the market and a complete after-sales system can not only guarantee the product quality, but also save a lot of time and cost in the later maintenance process. Our company offers high-quality chains for sale in Australia. With nearly 30 years of history, while having a complete service system, we are committed to providing customers with high-quality industrial chains that require less maintenance.

Maintenance Tips for Long-Lasting Chain and Drive Performance

In industrial equipment, the chain and drive system plays a crucial role. To ensure the long-term efficient operation of the equipment, daily maintenance cannot be ignored. Regular cleaning and lubrication can not only prevent wear and tear, but also extend the service life of chains and drives. In addition, checking the chain tension and the meshing condition of the gears can also help avoid operational interruptions.

The use of high-quality lubricants and correct tension settings can significantly improve the overall performance of the chain and drive system. If maintenance is ignored, it will not only lead to the failure of chains and drives, but also may cause overall damage to the equipment and increase the maintenance cost.

About Us

General Bearing Company is the sales agent of Ever-power in Australia, which is a modern enterprise integrating R&D, production and sales in chain drive field. For more than 20 years, our products have been sold well in more than 60 countries in Europe, America, Southeast Asia, the Middle East and Africa, and have been widely praised by customers all over the world.

The company produces transmission chain, conveyor chain, agricultural chain, lifting chain, special chain, stainless steel chain, motorcycle chain, motorcycle sprocket and other 8 categories of more than 50 series of thousands of specifications of chain drive products, widely used in industry, agriculture, forestry, mining and metallurgy, road paving, petroleum exploration, construction, light industry, household appliances, household chemicals, food, environmental protection, garage and other machinery operation.

Global Sales Network

We are the professional sales agent of Ever-power Group in Australia and have been deeply engaged in the field of transmission parts products for many years. With outstanding product quality and considerate service, we have established a good reputation in the local market. At present, our industrial chain has widely covered multiple states such as New South Wales, Victoria and Queensland, and the market territory is constantly expanding. In major cities such as Sydney, Melbourne and Brisbane, as well as important regions like Adelaide and Perth, there are stable supply channels and professional sales and service teams. No matter where our customers are located, we can respond promptly to their demands, provide high-quality industrial chains and comprehensive solutions, and help them ensure the efficient operation of production.

Advanced Production Equipment

Testing Devices

Chains and Sprockets

We not only provide high-quality chain products, but also supply many types of sprockets to meet the needs of different customers. We offer a wide range of sprockets, including type A (without hub), type B (with hub on one side), type C (with hub on both sides) and other structural forms. In addition, we offer single-row sprockets, double-row sprockets, and triple-row sprockets, which are suitable for different transmission needs. For special installation requirements, we also provide taper sleeve mounted sprockets and bearing type tensioner sprockets. For applications requiring higher transmission efficiency, we also offer double-drive sprockets with two single-row chains driven at the same time. Whether it is a standard or customized requirement, we can provide you with complete chain and sprocket solutions. If you also need sprockets, please contact us with your pictures or drawings.