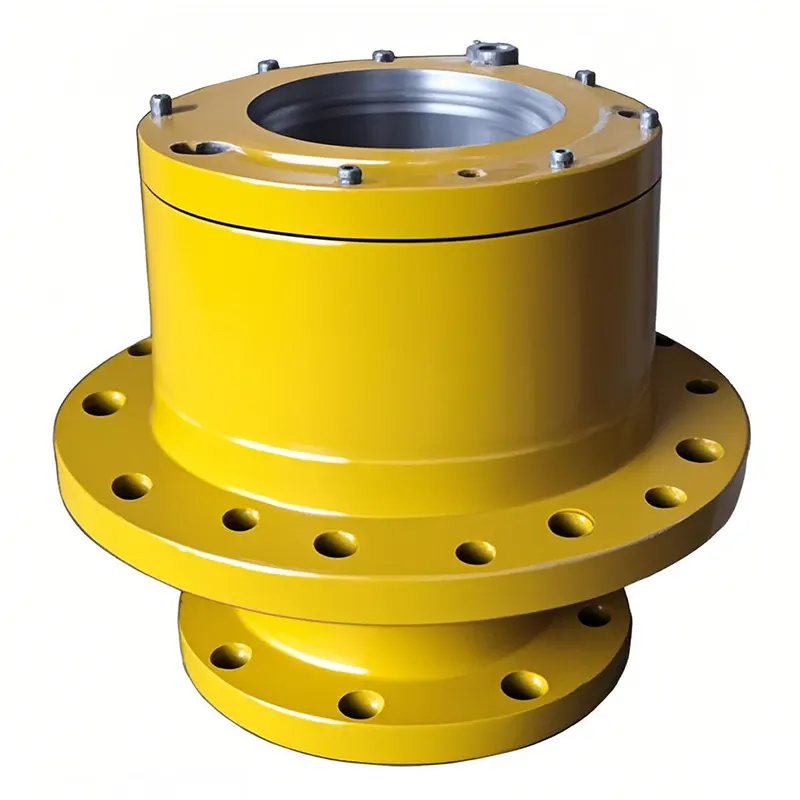

Track Drive Planetary Gearbox for Snowmobiles

The Track Drive Planetary Gearbox for Snowmobiles offers exceptional torque and durability, making it ideal for enhanced performance in snowy terrains.

| Feature | Description |

|---|---|

| Output Torque Range | 1000-450000 N¡¤m |

| Gear Ratios | i = 5.3 – 500 |

| Support | The gearbox has rotating housing flanges to fit tracks |

| Applicable Motors | Axial piston hydraulic motors, hydraulic orbit motors, or others |

| Hydraulic Motor Options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake |

| High Torque and Load Capacities | Designed to carry equipment over the roughest and steepest terrain |

| Motor Mounting | Designed to allow mounting of plug-in motors |

| Compact Design | Integral multi-disc parking brakes, while still keeping the drive compact |

| Material | Steel structure |

| Easy Maintenance | Filling and draining openings are reasonably located for easy reach |

| Front Mechanical Seal | Designed specifically for earth-moving machines |

| Compatibility | Technical data and installation dimensions of EP400T Series gearbox are the same as those of Rexroth GFT¡T Series and Bonfiglioli 700C Series, allowing interchangeability |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m.) |

| EP400T1 | 1300 | 6.09 | 1000 | 130 |

| EP401T1 | 2000 | 6.2 | 1000 | 270 |

| EP402T2 | 5000 | 12.4-37.1 | 3500 | – |

| EP403T2 | 7000 | 15.4-40 | 3500 | 270 |

| EP405T | 10000 | 20-80 | 3500 | 270 |

| EP405.4T | 11000 | 26-57 | 3500 | 280 |

| EP406AT | 17000 | 23-220 | 3500 | 430 |

| EP406T | 18000 | 28-140 | 3500 | 430 |

| EP406BT3 | 24000 | 63-136 | 3500 | 430 |

| EP407AT | 26000 | 38-136 | 3500 | 430-530 |

| EP407T3 | 36000 | 63-136 | 3500 | 530 |

| EP410T3 | 50000 | 62-177 | 3500 | 530 |

| EP413T3 | 60000 | 86-172 | 3500 | 610 |

| EP414T3 | 80000 | 76-186 | 3500 | 1200 |

| EP415T3 | 110000 | 81-215 | 3000 | 1200 |

| EP416T3 | 160000 | 87-255 | 3000 | 2000 |

| EP417T3 | 220000 | 123-365 | 3000 | 2000 |

| EP418T3 | 270000 | 166-364 | 3000 | 2000 |

| EP419T3 | 330000 | 161-306 | 2500 | 3000 |

| EP420T4 | 450000 | 296-421 | 2500 | 1700 |

Working Principle of Track Drive Planetary Gearbox for Snowmobiles

The planetary gear system consists of a sun gear, planet gears, a ring gear, and a planet carrier, working in unison to achieve speed reduction and torque multiplication. In this configuration, the sun gear is driven by the input shaft, causing the planet gears to rotate around it. These planet gears are mounted on the planet carrier, which also rotates. As the planet gears engage with the internal ring gear, they effectively reduce the output speed while increasing the torque. This design allows for compactness and efficiency, making it ideal for snowmobiles.

The Importance of Space Efficiency in Crawler Vehicles

Space efficiency is crucial for crawler vehicles, particularly when considering their operational capabilities and design constraints. The Track Drive Planetary Gearbox is significantly more compact compared to traditional gearboxes, allowing for better weight distribution and a lower center of gravity. This design not only enhances maneuverability but also improves overall performance in tight spaces. The reduced size of the planetary gearbox translates into more room for other essential components, leading to a more streamlined vehicle design and increased efficiency during operation.

Load Distribution in Track Drive Planetary Gearboxes

The Track Drive Planetary Gearbox is designed to ensure that the load is evenly distributed across all planetary gears. This unique design minimizes the risk of single-point failure by allowing each gear to share the load, reducing stress on any one component. As the sun gear rotates, the planetary gears engage with the ring gear, facilitating a balanced transfer of power. This not only enhances the durability of the gearbox but also improves overall efficiency, ensuring optimal performance in snowmobiles. The robust construction and innovative design make it a reliable choice for demanding conditions.

Track Drive Planetary Gearbox for Snowmobiles

The track drive planetary gearbox is essential for snowmobiles, as it must efficiently manage varying torque and speed demands. High torque is required for acceleration and climbing, while speed adjustments are crucial for maneuverability. Durability is paramount to withstand harsh weather and rough terrain, ensuring long-lasting performance.

Performance Requirements of Track Drive Planetary Gearbox

The track drive planetary gearbox must balance torque, speed, and durability, providing optimal performance in challenging snow conditions.

Customization Available for Track Drive

We offer the Track Drive Planetary Gearbox for Snowmobiles, but that’s not all. We also provide customization options to meet your specific needs and requirements. To help us better understand your customization needs, please provide the following information:

| Information Required | Description |

|---|---|

| 1. Power or Torque | Specify the required power or torque for the planetary gearbox. |

| 2. Gear Ratio | Indicate the desired gear ratio for optimal performance. |

| 3. Speed | Provide the operational speed required for your application. |

| 4. Input Type | Specify the type of input you require. |

| 5. Output Type | Indicate if you need spline, hollow, solid, or other types for output. |

| 6. Radial Load | Specify if there are external/radial loads on input or output ends. |

| 7. Operating Temperature | Provide the expected operating temperature range. |

| 8. Lifespan Requirements | Indicate any lifespan requirements for the gearbox. |

| 9. Special Requirements | Include any special needs such as continuous operation or shock loading. |

Track Drive Supplier

GBC is the Australian sales agent for Ever-power Group, specializing in providing high-quality drive solutions. One of our standout products is the Track Drive Planetary Gearbox for Snowmobiles, which delivers exceptional torque and efficiency, ensuring smooth operation in even the most challenging conditions. Its robust design and advanced engineering make it an ideal choice for those seeking reliability and performance in their snowmobile applications.

We urge all customers to consider customizing and purchasing this essential gearbox to enhance their snowmobiling experience. Don¡¯t miss out on the opportunity to elevate your equipment with our state-of-the-art solutions!