Planetary Slew Drive Gearbox for Excavators

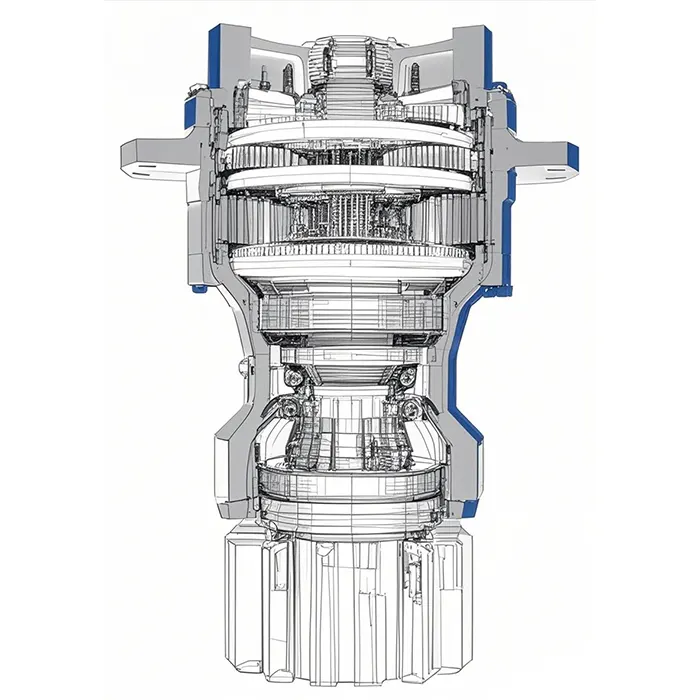

The Planetary Slew Drive Gearbox for Excavators is designed to provide precise and efficient rotational movement for heavy machinery. This gearbox ensures smooth operation and enhanced control, allowing excavators to perform intricate tasks with accuracy. By facilitating the slew motion, it improves productivity and stability, making it an essential component for construction and earthmoving projects.

Planetary Slew Drive Gearbox for Excavators

The Planetary Slew Drive Gearbox for Excavators offers superior torque and precision, making it an essential component for heavy-duty machinery. Its robust design ensures durability and reliability, optimizing the performance of excavators in various operating conditions.

| Specification | Details |

|---|---|

| Output torque range | 1000–180000 N.m |

| Gear ratios | i = 3.3–3000 |

| Support | Slew support (with flange mounted) |

| Output shaft | Splined or with integral pinion; output shafts supported by heavy duty capacity bearings |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors, IEC electric motors |

| Hydraulic motor options | Pressure relief valve, over-center valve, parking brake |

| Electric brake | DC and AC type |

| Hydraulic brake | Hydraulically released parking brake |

| 700L Series Slewing Drive | |||||

| Type | Max. torque (N.m) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP700L | 1000 | 1200 | 3.38-32 | 3500 | 50-400 |

| EP701L | 1800 | 2400 | 3.38-32 | 3500 | 50-400 |

| EP703AL | 2500 | 3500 | 12-175 | 3500 | 50-400 |

| EP705AL | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP705L | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP706AL | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP706L | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP707AL | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP707L | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP709AL | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP709L | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP711AL | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP711L | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP713L | 40000 | 55000 | 50-276 | 2500 | 400-1000 |

| EP715L3 | 70000 | 80000 | 54-242 | 2500 | 850-3200 |

| 700S Series Slewing Drive | |||||

| Type | Max. torque (N.m ) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP706S | 7700 | 10000 | 20-106 | 3500 | 400-1000 |

| EP707S | 10500 | 16500 | 25-134 | 3500 | 400-1000 |

| EP709S | 16000 | 26000 | 20-144 | 3500 | 400-1000 |

| EP710S | 18000 | 29000 | 36-52 | 3500 | 400-1000 |

| EP710BS | 23000 | 35000 | 110-176 | 3500 | 400-1000 |

| EP710DS | 27800 | 48500 | 32-181 | 3500 | 400-1000 |

| EP714S | 45000 | 68300 | 63-187 | 3000 | 600-2000 |

| EP715S | 65000 | 93300 | 63-212 | 3000 | 600-2000 |

| EP716S | 120000 | - | 63-1500 | 2500 | 600-2000 |

| EP717S | 180000 | - | 63-1500 | 2000 | 600-2000 |

Planetary Gearbox Slewing Drive VS Worm Gearbox

- Efficiency: Planetary gearboxes offer higher efficiency due to their design, minimizing energy loss compared to worm gearboxes which suffer from higher friction.

- Load Capacity: Planetary slewing drives can handle greater loads and torque, making them suitable for heavy-duty applications like excavators.

- Compact Size: Planetary designs are generally more compact, allowing for space-saving installations.

- Durability: Planetary systems typically have a longer lifespan due to lower wear and tear compared to worm gearboxes.

Selection of Planetary Slew Drive Gearbox for Excavators

When selecting the appropriate model and gear ratio for a Planetary Slew Drive Gearbox, it is crucial to consider several factors. First, evaluate the load torque requirements to ensure the gearbox can handle the application demands. Next, assess the input speed to match the operational needs effectively. Additionally, the working environment, including temperature and humidity, can impact performance, so choose a gearbox designed for those conditions. Space constraints must also be considered to ensure proper installation. We offer a variety of models and customizable gear ratios to meet diverse application requirements.

Does Planetary Gearbox Slewing Drive Need an Additional Brake?

The Planetary Slew Drive Gearbox for Excavators typically does not require an additional brake because it is designed to provide high torque and load-holding capacity. Its integrated braking features ensure stability during operation, effectively managing the forces experienced while slewing. However, in specific applications or under extreme conditions, an additional brake may enhance safety and control. Always consider the operational environment and requirements when determining the need for supplementary braking systems.

Slewing Drive Planetary Gearbox Manufacturer

GBC is the Australian sales agent for Ever-power Group, specializing in high-quality slewing drive solutions. Our Planetary Slew Drive Gearbox for Excavators is designed to provide maximum efficiency and durability, making it an essential component for heavy machinery. We pride ourselves on not only delivering top-notch products but also offering exceptional services and a comprehensive after-sales support system to ensure our clients have the best experience possible.

We invite all customers to customize their orders and request quotes tailored to their specific needs.

Additional information

| Edited by | Sylvia |

|---|

The Planetary Slew Drive Gearbox for Excavators is designed to provide precise and efficient rotational movement for heavy machinery. This gearbox ensures smooth operation and enhanced control, allowing excavators to perform intricate tasks with accuracy. By facilitating the slew motion, it improves productivity and stability, making it an essential component for construction and earthmoving projects.