PTO Shafts

PTO Shaft, namely Power Take-Off Shaft, also called PTO drive shaft, PTO driveline shaft, tractor PTO shaft, agricultural PTO shaft, is a device on a tractor used for outputting power. It can transfer the engine power of the tractor to other agricultural machinery to drive them to work. In agricultural production, the PTO shaft on a tractor plays a crucial role. It enables tractors to be used in conjunction with various agricultural machinery, thereby completing a wide range of agricultural operations such as sowing, harvesting, and ploughing.

Different PTO Shafts for Sale

The most distinctive feature of the ag PTO shaft is that it does not use an oil circuit or hydraulic motor in the middle. It directly transmits the power of the engine crankshaft to the outside through the power output shaft. That is, the PTO transmits the engine’s energy to the installed agricultural machinery with the highest efficiency. If it is well matched with the engine, it can achieve a relatively high energy utilization rate.

As one of the professional PTO shaft suppliers in Australia, we are committed to providing reliable PTO driveshafts for agricultural production. Our company offers various tractor PTO shaft types for sale to ensure that your agricultural production needs are met.

PTO Shafts by Application

PTO Shaft for Discbines

PTO Shaft for Feed Mixers

PTO Shaft for Flail Shredders

PTO Shaft for Round Balers

PTO Shaft for Square Balers

Standard PTO Shaft Series

G Series Spline PTO Shaft

L Series Lemon PTO Shaft

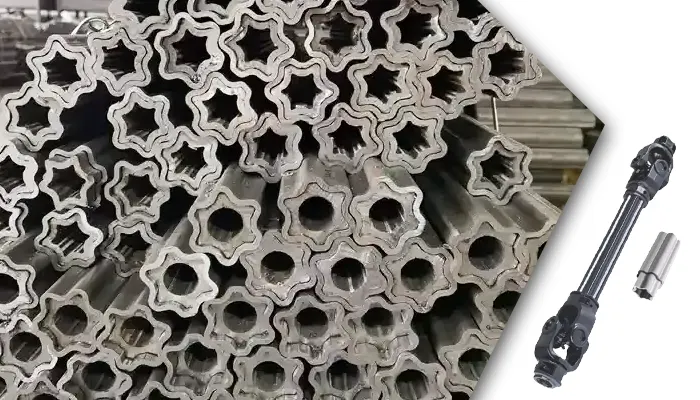

S Series Star PTO Shaft

T Series Triangular PTO Shaft

Other PTO Shafts

PTO Drive Shaft With Slip Clutch

Wide Angle PTO Shaft

PTO Shaft Parts

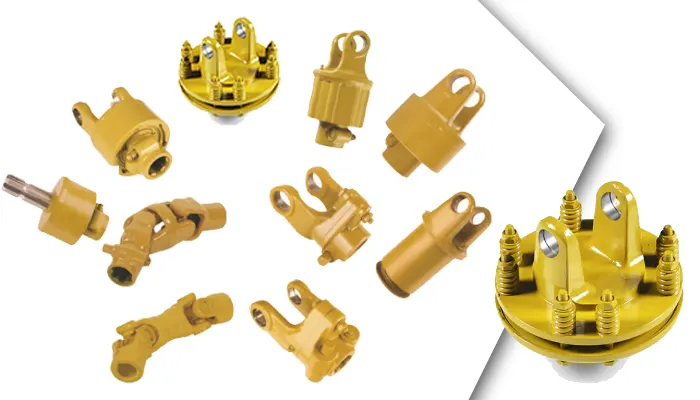

PTO Shaft End Yokes

PTO Shaft Torque Limiters

PTO Shaft Cross Kit / U-Joint

PTO Shaft Tube

PTO Shaft Safety Guard

PTO Shaft Wide Angle Joint

PTO Adaptors

Other Driveshafts

Industrial Cardan Shaft

Car Driveshaft

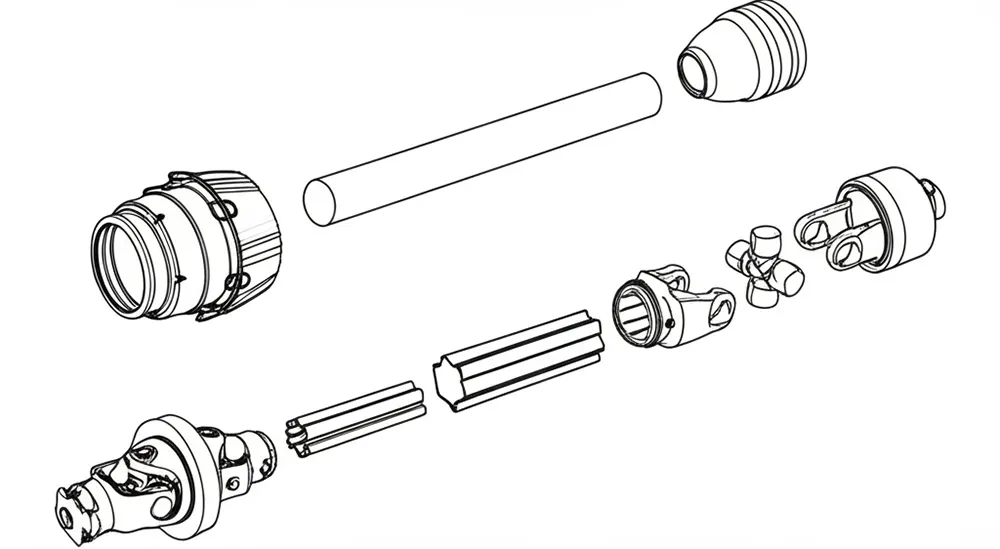

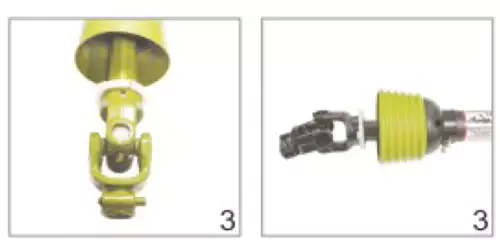

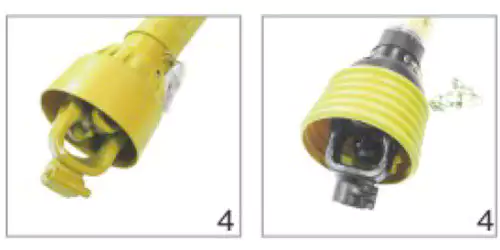

Component of PTO Shafts for Farm Equipment

The agricultural drive shaft is mainly composed of an input shaft, an output shaft and universal joints. Among them, the input shaft is usually installed at the engine end, and its function is to transfer the power generated by the engine to the interior of the drive shaft. The universal joint is an important component in the transmission shaft that connects the input shaft and the output shaft. It is usually composed of a mandshaft and a connecting pipe. The mandrel is usually made of alloy steel, while the connecting pipe is a thick-walled steel pipe, whose inner surface is processed into a ball-bearing groove for installing the balls. The output shaft is usually installed at the end of the drive shaft to transfer power to the wheels or machinery.

540 rpm PTO Shaft & 1000 rpm PTO Shaft

In international standards, the initial PTO shaft speed was 540 r/min, and later there were 2 types, 540 r/min and 1,000 r/min. The diameter of the shaft for 540 r/min was uniformly 35 mm with a 6-tooth spline, and the diameter of the shaft for 1,000 r/min was uniformly 44 mm with a 21-tooth spline. The 1000rpm PTO shaft is only installed on high power (PTO output > 73.53kW) tractors. Nowadays, there are various PTO speeds for tractors, 540r/min, 720r/min, 750r/min, 760r/min, 850r/min, 1000r/min, 1300r/min, etc. Various PTO speed combinations can be realized through the shift mechanism.

Generally speaking, most of the tractors nowadays are equipped with 2 speed combinations as standard, such as: 540r/min and 760r/min, 540r/min and 1000r/min, 760r/min and 850r/min, 760r/min and 1000r/min. 540 rpm PTO shaft is used for normal operation, and 1000rpm PTO shaft is for heavy duty operation ( Of course the farm equipment used is also specialized for 1000rpm PTO), while 760r/min is used for light duty work (fertilizing, composting, spraying, etc.) that can be performed at 540r/min without having to increase the engine speed (about 1450~1600r/min). 760r/min PTOs are called economical PTOs and are sometimes marked by tractor manufacturers as 540 E PTO shaft. This is because a 760r/min PTO shaft offers significant savings in fuel consumption, depending on how it is used.

How to Choose the Right PTO Shaft?

The following factors need to be considered when choosing the appropriate PTO shaft of tractor:

- Equipment type: Ensure that the tractor drive shaft is compatible with your tractor or agricultural machinery.

- Power demand: Select the appropriate power take off drive shaft according to the power requirements of agricultural machinery.

- Shaft length and connection method: Measure the required length of the PTOdriveline and confirm the connection type (such as 6 keys or 21 keys).

- Working environment: Choose atractor power take off shaft suitable for your agricultural environment, such as corrosion-resistant or heavy-duty design.

Our technical team can provide professional advice to help you select the best tractor PTO drive shaft and farm PTO shafts.

Common PTO Shaft Problems and Solutions

The PTO (Power Take Off) drive shaft is the core component in equipment such as tractor pto and engineering vehicles for transmitting power to external devices (such as harvesters, pumps, etc.). Its malfunction may affect the efficiency of the equipment and even lead to shutdown. The following are the common faults we encountered during the operation process and their solutions, which help users quickly locate the problems and reduce maintenance costs.

| Problems | Fault Symptoms | Solutions |

|---|---|---|

| Abnormal Noise in PTO Shaft | Periodic “buzzing” or “clacking” sounds during operation, worsening on uphill slopes. | 1. Check if the angle between tractor PTO shaft sections is too large; adjust to standard range. 2. Inspect the temperature of universal joints; replace cross shafts or bearings if overheated. 3. Correct the dynamic balance of the PTO drive to ensure runout meets standards. |

| PTO Shaft Breakage | Sudden fracture under load or fatigue cracks due to long-term vibration. | 1. Increase the diameter of the shaft tube for higher strength or adopt a segmented design with additional intermediate supports. 2. Replace power take off shafts with insufficient design safety factors. 3. Regularly check dynamic balance to avoid resonance. |

| Insufficient PTO Power Output | Difficulty starting the equipment or power interruption under load, accompanied by a “stop” indicator light. | 1. Check the fuel system (fuel tank, fuel delivery pump, injectors) for leaks or blockages. 2. Clean or replace the air filter to ensure proper air intake. 3. Adjust injection timing and valve clearances; repair turbocharger failures. |

| Abnormal PTO Switch Voltage | Excessively high or low switch voltage, leading to equipment failure to start or false triggering of protection systems. | 1. Check circuits, connectors, and relays for short circuits or open circuits. 2. Inspect sensors and control module signals; repair or replace faulty components. 3. Replenish grease to prevent overheating-induced voltage fluctuations. |

| PTO Shaft Vibration | Periodic vehicle vibration during operation, with differences noticeable during acceleration and coasting. | 1. Reassemble universal joint yokes to ensure consistent alignment. 2. Correct bending or twisting of the PTO shaft; repair or replace deformed parts. 3. Tighten loose fasteners to reduce dynamic imbalance. |

PTO Shaft Maintenance and Installation Guide

Correct maintenance and installation of PTO shaft is the key to ensuring the efficient operation of agricultural machinery. The following guide details how to replacing PTO shaft, replacing yoke on PTO shaft, cutting PTO drive shaft, shortening PTO shaft, connecting PTO shaft to tractor, measuring PTO shaft and PTO drive shaft assembly, which help you optimize the performance of the drive shaft for tractor.

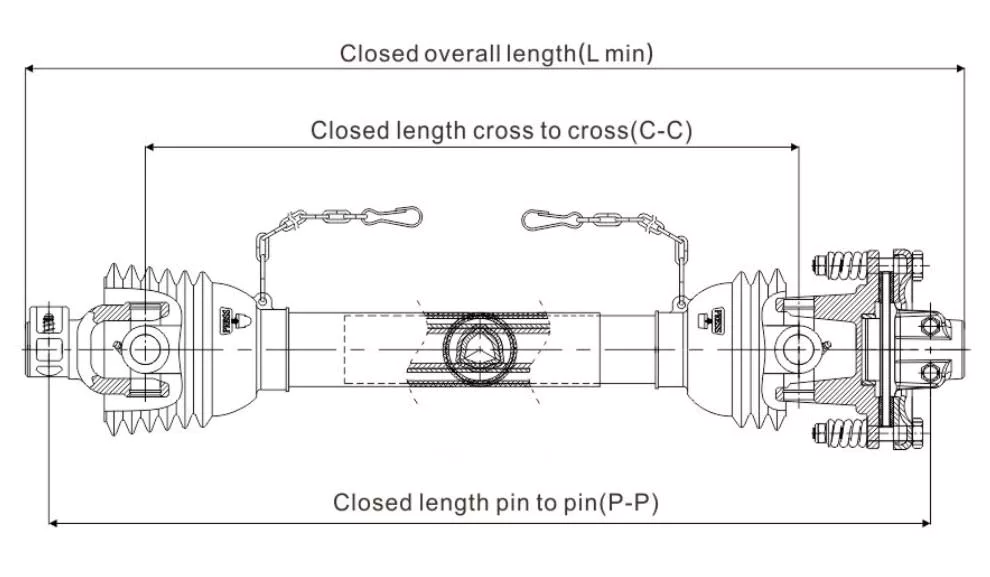

How to Measure the PTO Shaft?

Measuring PTO shaft is a key step to ensure the matching of the PTO shaft with the equipment. The following are the measurement methods:

- Determine the connection points: Locate the positions of the output shaft of the tractor PTOand the input shaft of the agricultural machinery.

- Measure the distance: Measure the distance between the two shafts to ensure the length of the tractor PTOdrive shaft in the maximum and minimum extension states.

- Check the key type: Record the key type of the PTOdriveline shaft (such as 6 keys or 21 keys) to ensure compatibility.

- Consider the Angle: Ensure that the agricultural drive shaft is not damaged due to excessive Angle during operation.

- Record data: Use the measurement results for the selection or customization of farm equipment drive shafts.

Accurate measuring PTO shaft avoids installation problems and extends the service life of tractor implement drive shafts.

How to Replace the PTO Shaft?

Replacing PTO shaft is an important step in extending the service life of agricultural machinery. The following is the detailed process for replacing the power take off shaft:

- Disconnect the power: Turn off the tractor and disconnect the power source of the tractor PTOshaft to ensure safe operation.

- Disassemble the old shaft: Loosen the bolts or clips connecting the PTOdrive shaft and carefully remove the old PTO

- Check the new shaft: Confirm that the model, length and key type of the new tractor power take off drive shaft match the equipment.

- Install the new shaft: Attach the new tractor PTOdriveline to the tractor and farm equipment and fasten all connectors.

- Test run: Start the tractor and run it at low speed to ensure tractor implement drive shaft works properly without abnormal vibration or noise.

Regular inspection and replacing PTO shaft can effectively reduce equipment failures and ensure the efficient operation of power take off PTO shaft.

How to Replace the Yoke on the PTO Shaft?

Replacing yoke on PTO shaft is a common operation for repairing broken connection parts. The following are the steps:

- Disassemble the PTOshaft: Remove the PTO drive shaft from the tractor and agricultural machinery and place it on a stable workbench.

- Remove the old yoke: Use a special tool (such as a wrench or a pin puller) to remove the pins or bolts that fix the tractor PTOdrive shaft yoke.

- Install the new yoke: Select the new component that matches the original yoke, install it on the PTOdriveline shaft, and secure the pins or bolts.

- Check alignment: Ensure that the new yoke is aligned with other components of the agricultural drive shaft and is not loose.

- Re-installation: Reconnect the repaired farm equipment drive shafts to the equipment and test run it to confirm that it works properly.

Note: Selecting a high-quality yoke improves the durability of power take off shaft in tractor.

How to Cut the PTO Drive Shaft?

Cutting a PTO shaft is an important step in adjusting the length of the PTO shaft to fit the equipment. The following is the operation method:

- Measure the required length: Determine the ideal length of the tractor drive shaft and ensure to leave a margin of 1-2 centimeters for flexible connection.

- Mark the cutting points: Use a marking pen to mark the positions that need to be cut on the inner and outer tubes of the PTOdrive

- Cutting the shaft tube: Carefully cut the PTOshafts using an Angle grinder or tube cutter to ensure a smooth cut.

- Polish the edge: Process the cut with sandpaper or a grinder to remove burrs to prevent damage to farm PTOshafts seals.

- Test installation: Install the cut tractor PTOdriveline onto the device and check if it is suitable.

Safety tip: When cutting the PTO drive shaft, be sure to wear protective glasses and gloves.

How to Shorten the PTO Shaft?

Shortening PTO shaft is the key to ensuring a perfect match between PTO shaft on a tractor and agricultural machinery. The following are the detailed steps:

- Measure the length: Measure the distance between the tractor PTOshaft and the agricultural machinery to determine the length that needs to be shortened.

- Disassemble the shaft tubes: Separate the inner and outer tubes of the PTOdrive shaft and mark the parts that need to be shortened.

- Cutting pipe materials: Use professional tools to cut the inner and outer pipes of the PTOdriveline shaft to ensure that the shortened lengths of the two pipes are consistent.

- Cleaning and assembly: After grinding the cut, reassemble the tractor PTOshaft and apply lubricant to reduce friction.

- Test run: Mount the short PTOdrive shaft onto the tractor and test it at low speed to ensure smooth operation.

Shortening a PTO shaft requires precise measurement and professional tools. It is recommended to be operated by professionals.

How to Connect the PTO Shaft to a Tractor?

Connecting PTO shaft to tractor is a necessary step before using agricultural machinery. The following is the operation guide:

- Check compatibility: Confirm the key type of the tractor PTOshaft.

- Align the shaft end: Align the yoke head of the PTOdrive shaft with the PTO output shaft of the tractor to ensure correct insertion.

- Fixed connection: Use locking pins or bolts to fix the PTOshaft to ensure a firm connection.

- Install protective cover: Install a protective cover for PTOshafts to prevent injury from rotating parts.

- Test connection: Start the tractor and run it at low speed to check if farm PTOshafts runs smoothly.

Correctly connecting PTO shaft to tractor can ensure the safe and efficient operation of tractor power take off drive shaft.

Assembly of PTO Drive Shaft

The PTO drive shaft assembly needs to ensure that all components are correctly installed to guarantee performance. The following are the assembly steps:

- Prepare components: Collect all components of the PTOshaft, including inner and outer tubes, yokes, universal joints and protective covers.

- Assemble the universal joint: Connect the universal joint to the yoke of the tractor PTOshaft and ensure that the pins or bolts are firmly fixed.

- Install the shaft tubes: Insert the inner and outer tubes into the PTOdrive shaft, ensure smooth extension and retraction, and apply lubricant.

- Fixed protective cover: Install a protective cover for PTOdriveline to prevent the exposure of rotating parts.

- Test assembly: Install the assembled PTOshafts onto the device and run it at low speed to check stability.

High-quality PTO drive shaft assembly can enhance the durability and safety of power take off drive shaft.

|

|

|

|

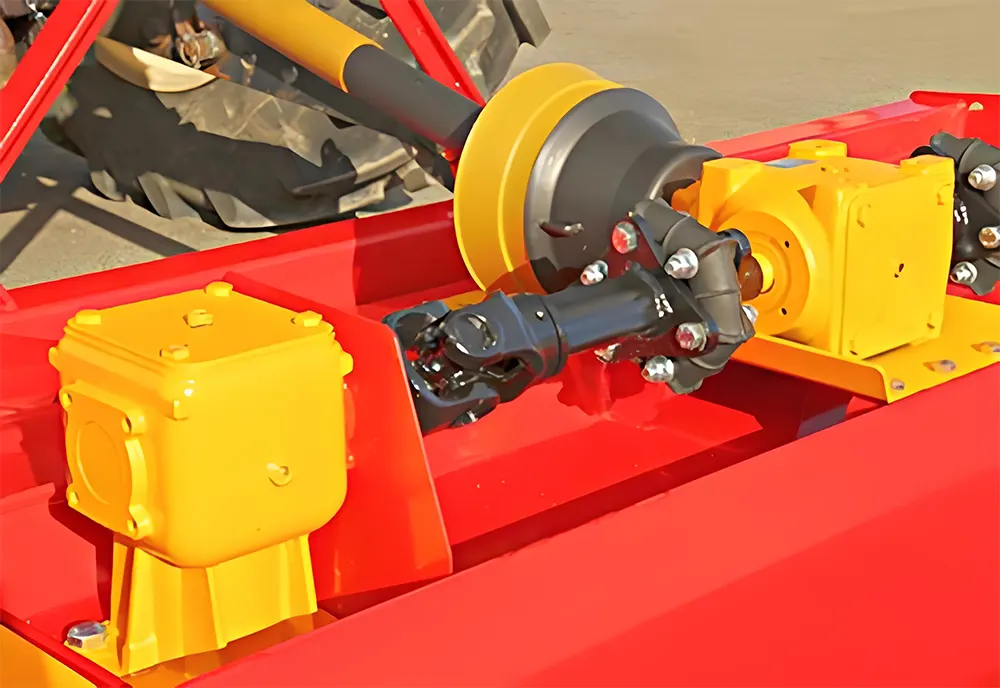

PTO Shaft Gearbox

Enhance the Power Transmission Efficiency of Agricultural Machinery

The PTO shaft gearbox is an indispensable component in agricultural machinery. When used in conjunction with the PTO shaft, it provides efficient power conversion and transmission for agricultural machinery. The agricultural gearbox ensures that the power take off drive shaft is perfectly matched with various agricultural machinery (such as lawn mowers, rotary tillers or seeders) by adjusting the rotational speed and torque. Our PTO shaft gearbox, made of high-strength materials and manufactured with precision, can withstand high-load working conditions and extend the service life of tractor implement drive shafts.

By rationally choosing the PTO shaft gearbox, you can optimize the performance of the pto driveline, reduce energy loss and improve agricultural production efficiency. During installation, ensure that the tractor PTO drive shaft is securely connected to the gearbox and regularly check the condition of the lubricating oil to keep PTO shafts running smoothly. Whether it is heavy agricultural machinery or small garden tractor pto shaft, we offer a variety of pto gearboxes to meet the needs of different agricultural scenarios. Choose our PTO shaft gearbox for reliable power support for your farm equipment drive shafts!

About Us – Reliable PTO Shafts Manufacturer and Supplier in Australia

We are dedicated to the production and development of PTO drive, agricultural machinery drive shafts and all supporting accessories, and now we have long-term close co-operation with a number of countries in the European market (Italy, Germany, France, Ukraine, etc.) in the American market (USA, Mexico, Brazil, Chile, etc.) in Russia, and in the Southeast Asian market (Thailand, Malaysia, Indonesia, etc.) in the Oceania market (New Zealand, Australia, etc.). At present, the factory covers an area of up to more than 20 acres of fields, and we have ISO, CE and other certificates.

As the official sales agent of Ever-power Group in Australia, GBC has been deeply engaged in the industry for many years and enjoys a good reputation and professional service capabilities. Our PTO shafts (power output shaft) products are highly favored in the market for their excellent quality, stable performance and efficient transmission efficiency. At present, these premium PTOS shafts are fully covered in important states such as New South Wales, Victoria and Queensland. In bustling cities such as Sydney, Melbourne and Brisbane, as well as key cities like Adelaide and Perth, there is a hot sales trend, providing reliable power support for the operation of equipment in local agriculture, industry and other fields.

PTO Shafts Process Flow

Workblank Cutting > Workblank Preparation > Forging Preparation > Turn-milling Machining > Drill Earhole > Boring Earhole > Spline Broaching > Grove Milling > Cutting > Pressure Pipe > Drill Pin > Burring > U-J oints Assembly > Driving Shaft assembly > Painting & Marking > Plastic Shield Assembly > Packing > Loading > Deliverying

Workblank Cutting

Workblank Preparation

Forging Preparation

Boring Earhole

Drill Earhole

Turn-milling Machining

Spline Broaching

Grove Milling

Cutting

Burring

Drill Pin

Pressure Pipe

U-J oints Assembly

Driving Shaft Assembly

Painting & Marking

Loading

Packing

Plastic Shield Assembly

Deliverying

PTO Shaft Factory Show

Visit Our Factory

Lathe Equipment

Test Equipment

PTO Shafts Packaging

Contact Us

Need a high-quality PTO shaft or tractor power take-off shaft? Contact us today to buy PTO shaft solutions tailored to your needs! Our team offers expert farm equipment drive shaft selection advice and customization services to optimize your machinery’s performance. Get competitive tractor PTO shaft prices by reaching out now!