Planetary Slew Drive Gearbox for Robotic Arms

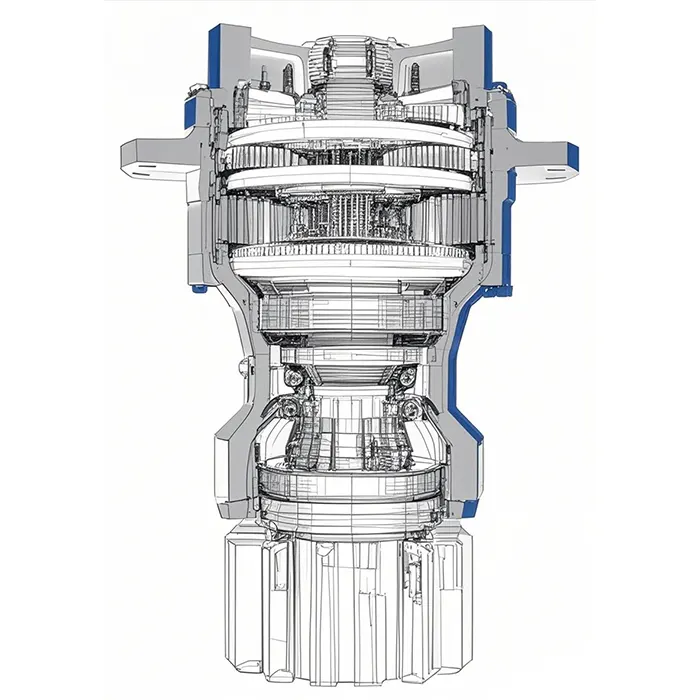

The Planetary Slew Drive Gearbox for Robotic Arms is essential for precise movement and positioning. This gearbox facilitates smooth rotation and accurate control, enabling robotic arms to perform complex tasks with ease. Its compact design and high torque capacity make it ideal for applications in automation, manufacturing, and robotic manipulation, enhancing overall efficiency and functionality.

Planetary Slew Drive Gearbox for Robotic Arms

The Planetary Slew Drive Gearbox is designed for precision and efficiency in robotic arm applications, offering high torque and compact design. Its robust construction ensures durability and reliability, making it ideal for demanding tasks in automation and robotics.

| Specification | Details |

|---|---|

| Output torque range | 1000–180000 N.m |

| Gear ratios | i = 3.3–3000 |

| Support | Slew support (with flange mounted) |

| Output shaft | Splined or with integral pinion; output shafts supported by heavy duty capacity bearings |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors, IEC electric motors |

| Hydraulic motor options | Pressure relief valve, over-center valve, parking brake |

| Electric brake | DC and AC type |

| Hydraulic brake | Hydraulically released parking brake |

| 700L Series Slewing Drive | |||||

| Type | Max. torque (N.m) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP700L | 1000 | 1200 | 3.38-32 | 3500 | 50-400 |

| EP701L | 1800 | 2400 | 3.38-32 | 3500 | 50-400 |

| EP703AL | 2500 | 3500 | 12-175 | 3500 | 50-400 |

| EP705AL | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP705L | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP706AL | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP706L | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP707AL | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP707L | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP709AL | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP709L | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP711AL | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP711L | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP713L | 40000 | 55000 | 50-276 | 2500 | 400-1000 |

| EP715L3 | 70000 | 80000 | 54-242 | 2500 | 850-3200 |

| 700S Series Slewing Drive | |||||

| Type | Max. torque (N.m ) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP706S | 7700 | 10000 | 20-106 | 3500 | 400-1000 |

| EP707S | 10500 | 16500 | 25-134 | 3500 | 400-1000 |

| EP709S | 16000 | 26000 | 20-144 | 3500 | 400-1000 |

| EP710S | 18000 | 29000 | 36-52 | 3500 | 400-1000 |

| EP710BS | 23000 | 35000 | 110-176 | 3500 | 400-1000 |

| EP710DS | 27800 | 48500 | 32-181 | 3500 | 400-1000 |

| EP714S | 45000 | 68300 | 63-187 | 3000 | 600-2000 |

| EP715S | 65000 | 93300 | 63-212 | 3000 | 600-2000 |

| EP716S | 120000 | - | 63-1500 | 2500 | 600-2000 |

| EP717S | 180000 | - | 63-1500 | 2000 | 600-2000 |

Planetary Gearbox Slewing Drive VS Worm Gearbox

- Efficiency: Planetary gearboxes offer higher efficiency than worm gearboxes, reducing energy loss.

- Torque Capacity: Planetary systems provide greater torque output, ideal for heavy-duty applications.

- Backlash: Planetary designs typically exhibit lower backlash, ensuring precise control for robotic arms.

- Size and Weight: Planetary slewing drives are more compact and lighter, enhancing the robotic arm's overall performance.

Selection of Planetary Slew Drive Gearbox for Robotic Arms

When selecting the appropriate model and gear reduction ratio for a Planetary Slew Drive Gearbox for robotic arms, it is essential to consider several factors. Firstly, evaluate the load torque to ensure the gearbox can handle the required force. Next, assess the input speed to match the operational needs of your application. The working environment, including temperature and humidity, also plays a crucial role in the performance and longevity of the gearbox. Additionally, consider the available installation space to ensure a proper fit. We offer a variety of models and support customizable gear reduction ratios to meet your specific requirements.

Does Planetary Gearbox Slewing Drive Need an Additional Brake?

The Planetary Slew Drive Gearbox for robotic arms typically does not require an additional brake, as it is designed to provide precise control and hold loads effectively. The inherent design of the planetary gearbox allows for minimal backlash and stable positioning, which can often eliminate the need for supplementary braking systems. However, in applications with high dynamic loads or where added safety is a priority, an additional brake may still be considered.

Slewing Drive Planetary Gearbox Manufacturer

GBC is the Australian sales agent for Ever-power Group, specializing in high-quality slewing drive planetary gearboxes. Our Planetary Slew Drive Gearbox for Robotic Arms is designed for precision and reliability, making it ideal for various applications. We pride ourselves on offering exceptional service and a comprehensive after-sales support system to ensure our customers' satisfaction.

We invite all customers to explore our customizable solutions and request a quote today. Experience the difference with our top-tier products and dedicated service!

Additional information

| Edited by | Sylvia |

|---|

The Planetary Slew Drive Gearbox for Robotic Arms is essential for precise movement and positioning. This gearbox facilitates smooth rotation and accurate control, enabling robotic arms to perform complex tasks with ease. Its compact design and high torque capacity make it ideal for applications in automation, manufacturing, and robotic manipulation, enhancing overall efficiency and functionality.