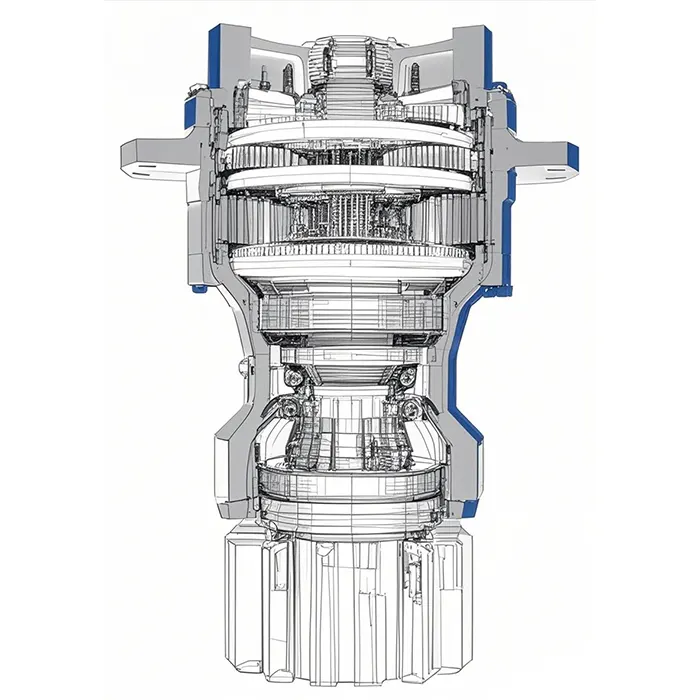

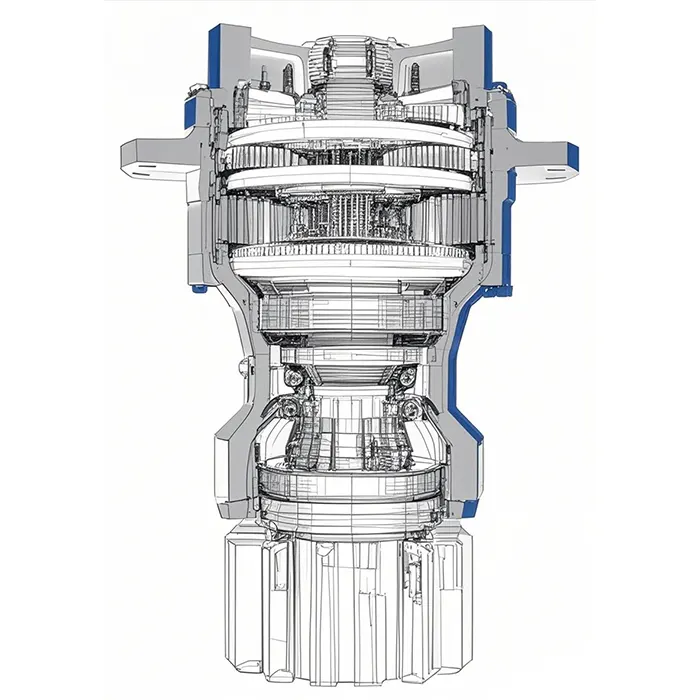

Planetary Slew Drive Gearbox for Mining Excavators

The Planetary Slew Drive Gearbox for Mining Excavators is designed to enhance the efficiency and precision of heavy machinery. This robust gearbox provides smooth rotational movement, enabling excavators to perform complex tasks with ease. Its compact design ensures optimal space utilization while delivering high torque and reliability, essential for navigating challenging mining environments and improving overall operational productivity.

Planetary Slew Drive Gearbox for Mining Excavators

The Planetary Slew Drive Gearbox is designed specifically for mining excavators, providing exceptional torque and reliability under extreme conditions. Its compact design and high load capacity enhance operational efficiency while reducing maintenance costs.

| Specification | Details |

|---|---|

| Output torque range | 1000–180000 N.m |

| Gear ratios | i = 3.3–3000 |

| Support | Slew support (with flange mounted) |

| Output shaft | Splined or with integral pinion; output shafts supported by heavy duty capacity bearings |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors, IEC electric motors |

| Hydraulic motor options | Pressure relief valve, over-center valve, parking brake |

| Electric brake | DC and AC type |

| Hydraulic brake | Hydraulically released parking brake |

| 700L Series Slewing Drive | |||||

| Type | Max. torque (N.m) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP700L | 1000 | 1200 | 3.38-32 | 3500 | 50-400 |

| EP701L | 1800 | 2400 | 3.38-32 | 3500 | 50-400 |

| EP703AL | 2500 | 3500 | 12-175 | 3500 | 50-400 |

| EP705AL | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP705L | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP706AL | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP706L | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP707AL | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP707L | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP709AL | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP709L | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP711AL | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP711L | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP713L | 40000 | 55000 | 50-276 | 2500 | 400-1000 |

| EP715L3 | 70000 | 80000 | 54-242 | 2500 | 850-3200 |

| 700S Series Slewing Drive | |||||

| Type | Max. torque (N.m ) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP706S | 7700 | 10000 | 20-106 | 3500 | 400-1000 |

| EP707S | 10500 | 16500 | 25-134 | 3500 | 400-1000 |

| EP709S | 16000 | 26000 | 20-144 | 3500 | 400-1000 |

| EP710S | 18000 | 29000 | 36-52 | 3500 | 400-1000 |

| EP710BS | 23000 | 35000 | 110-176 | 3500 | 400-1000 |

| EP710DS | 27800 | 48500 | 32-181 | 3500 | 400-1000 |

| EP714S | 45000 | 68300 | 63-187 | 3000 | 600-2000 |

| EP715S | 65000 | 93300 | 63-212 | 3000 | 600-2000 |

| EP716S | 120000 | - | 63-1500 | 2500 | 600-2000 |

| EP717S | 180000 | - | 63-1500 | 2000 | 600-2000 |

Planetary Gearbox Slewing Drive VS Worm Gearbox

- Efficiency: Planetary slew drives offer higher efficiency compared to worm gearboxes, leading to reduced energy consumption.

- Torque Capacity: Planetary gearboxes can handle greater torque loads, making them suitable for heavy-duty applications like mining excavators.

- Size and Weight: Planetary drives are typically more compact and lighter than worm gearboxes, allowing for better integration in machinery.

- Backlash: Planetary drives generally have lower backlash, resulting in improved precision and control in operations.

Selection of Planetary Slew Drive Gearbox for Mining Excavators

Choosing the right model and gear ratio for a Planetary Slew Drive Gearbox involves careful consideration of several factors. First, assess the load torque and input speed requirements of your excavator to ensure optimal performance. Additionally, the working environment, including temperature and humidity, plays a crucial role in determining the suitability of a gearbox. Installation space must also be taken into account to ensure a proper fit. We offer a variety of models tailored to different applications and support customized gear ratios to meet your specific needs, ensuring efficient operation in diverse conditions.

Installations

To install the Planetary Slew Drive Gearbox for Mining Excavators, follow these steps:

- Ensure the excavator is on a stable surface and powered off.

- Remove the old gearbox, taking note of the wiring and connections.

- Position the new planetary slew drive gearbox in alignment with the mounting points.

- Securely fasten the gearbox using the appropriate bolts.

- Reconnect the wiring and test the system for proper operation.

Slewing Drive Planetary Gearbox Manufacturer

GBC is the Australian sales agent for Ever-power Group, specializing in high-quality slewing drive planetary gearboxes. Our Planetary Slew Drive Gearbox for mining excavators is designed to provide exceptional performance, reliability, and efficiency in demanding environments. We pride ourselves on delivering superior service and a comprehensive after-sales support system to ensure our clients' needs are met at every stage.

We invite all customers to customize their orders and request quotes to experience the excellence of our products firsthand.

Additional information

| Edited by | Sylvia |

|---|

The Planetary Slew Drive Gearbox for Mining Excavators is designed to enhance the efficiency and precision of heavy machinery. This robust gearbox provides smooth rotational movement, enabling excavators to perform complex tasks with ease. Its compact design ensures optimal space utilization while delivering high torque and reliability, essential for navigating challenging mining environments and improving overall operational productivity.