Machinable Bore Sprocket for ANSI 60 Roller Chain (3/4″ Pitch)

The Machinable Bore Sprocket for ANSI 60 Roller Chain (3/4″ Pitch) is designed for durability and precision in various industrial applications. This sprocket allows for custom bore modifications, ensuring a perfect fit for your specific needs. GBC proudly offers high-quality Machinable Bore Sprockets in Australia.

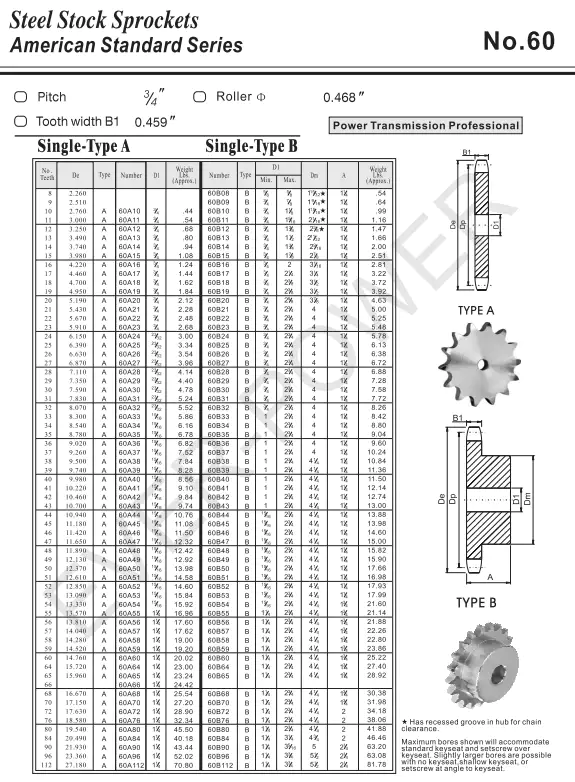

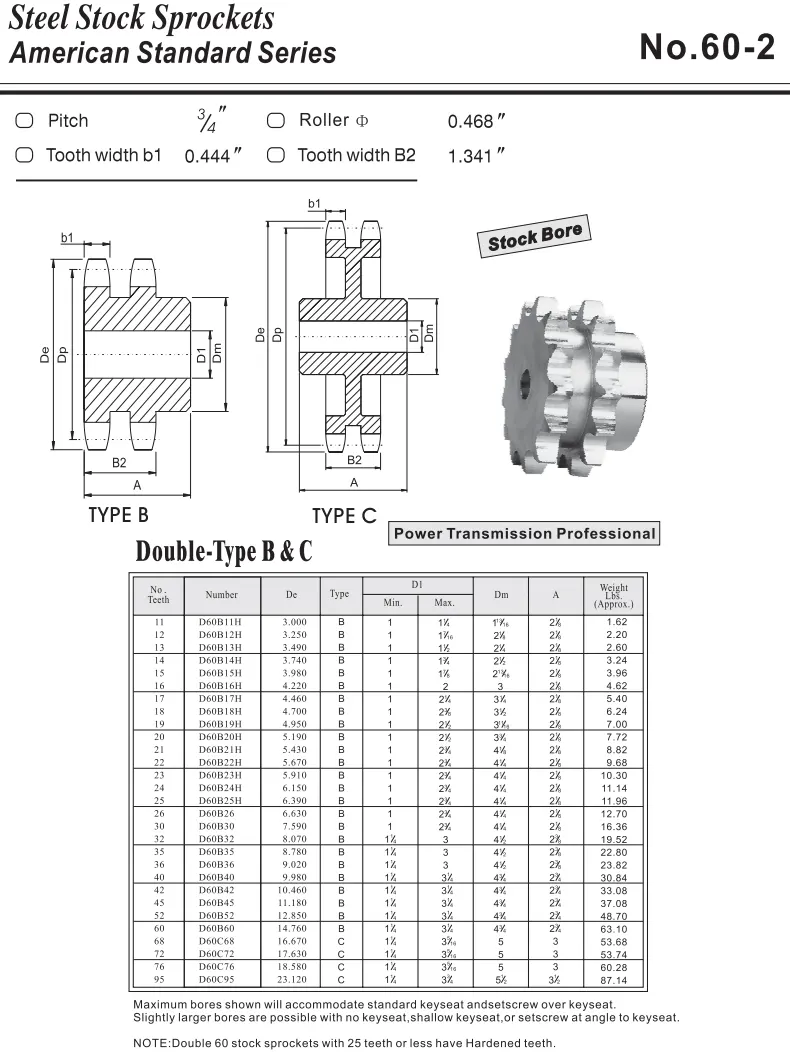

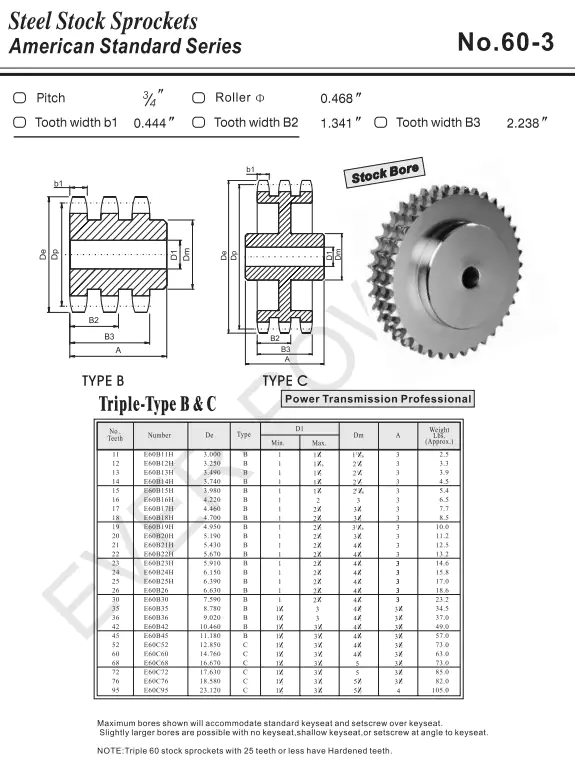

Specifications for Machinable Bore Sprocket for ANSI 60 Roller Chain (3/4" Pitch)

A machinable bore sprocket is a specialized type of sprocket designed for use in mechanical systems that require precise alignment and fit. It plays a crucial role in transferring rotary motion between two shafts through a roller chain. The Machinable Bore Sprocket for ANSI 60 Roller Chain (3/4" Pitch) is specifically designed to enhance performance, ensuring compatibility with a wide range of applications.

3/4 Inch Bore Sprocket Basic Structure and Customization

The structure of a machinable bore sprocket generally includes the sprocket teeth, a bore that can be machined to precise specifications, and a hub that provides mounting capability. Customization options are essential to meet specific operational requirements:

- Material: Options include high carbon steel, alloy steel, or stainless steel, chosen based on the application's demands for strength and corrosion resistance.

- Tooth Profile: Different tooth shapes may be required depending on the application, allowing for tailored performance.

- Number of Teeth: The number of teeth significantly impacts the speed ratio between the driving and driven shafts, making it a critical parameter.

- Dimensions: Precise measurements, including diameter and width, must be provided to ensure the sprocket fits perfectly within the system.

- Bore: The bore size must precisely match the shaft it will be installed on to maintain functionality and efficiency.

- Keyway: Optional keyways can be incorporated into the design to ensure proper alignment and fit with the shaft.

- Surface Treatment: Treatments such as rust prevention can be applied to enhance durability and longevity in challenging environments.

Material and Manufacturing Process of 3/4 Inch Bore Sprocket

At GBC - Ever-power Australia Agency, our machinable bore sprockets are crafted from high-quality materials and undergo rigorous manufacturing processes to guarantee superior strength and reliability. We select materials based on specific requirements, ensuring that each sprocket meets the intended use effectively.

- Material: Choices include high carbon steel, alloy steel, or stainless steel, depending on the desired properties and application constraints.

- Manufacturing Process: The production process encompasses material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, and quality testing to ensure each sprocket meets high standards.

3/4 Inch Bore Sprocket Applications

Machinable Bore Sprockets for ANSI 60 Roller Chains are versatile and find applications across various industries, including:

- Heavy machinery and equipment, where high torque and reliability are essential.

- Food processing and packaging, where hygienic standards are crucial.

- Chemical and pharmaceutical sectors, requiring resistant and durable components.

- Assembly lines, where precision and efficiency are paramount.

- Logistics and warehousing, where durability and performance under load are critical.

Maintenance and Troubleshooting

Ensuring the longevity and optimal performance of machinable bore sprockets is vital and requires regular maintenance. Here are some essential maintenance points to consider:

- Daily Inspection: Regular checks for signs of wear, damage, or misalignment can help prevent larger issues down the line.

- Cleaning: Keeping the sprocket free of dirt, debris, and excessive lubrication is important for its functionality and lifespan.

- Lubrication: Proper lubrication reduces friction and ensures smooth operation, which is essential for performance.

- Adjustment and Calibration: Periodic adjustments and calibrations are necessary to maintain proper tension and alignment.

Common issues that can arise include tooth skipping, breakage, wear, excessive noise, and chain disengagement. Addressing these problems promptly can prevent significant downtime:

- Tooth Skipping: Misalignment or worn-out teeth should be checked and replaced as necessary to maintain reliability.

- Breakage: Inspect for cracks and signs of fatigue, replacing the sprocket if any are found.

- Wear: Regular monitoring for wear will ensure timely replacements, especially when teeth show excessive wear.

- Excessive Noise: Proper lubrication and alignment should be confirmed, along with checking for damaged chain links.

- Chain Disengagement: Verify chain tension and inspect for any faulty links or sprocket teeth.

Other Types of Sprockets

Alongside the Machinable Bore Sprocket for ANSI 60 Roller Chain, we offer a variety of other sprockets to accommodate diverse needs, including:

- Platewheel sprockets, designed for light-duty applications.

- Idler sprockets, used to maintain tension in roller chains.

- QD sprockets, featuring a quick-disconnect design for easy installation and removal.

- Taper lock sprockets, known for their ability to provide secure mounting without the need for additional components.

3/4 Inch Bore Sprockets Supplier - GBC

GBC is the sales agent for Ever-power Group in Australia, and we are one of the leading sprocket suppliers in the country. Our Machinable Bore Sprockets for ANSI 60 Roller Chain (3/4" Pitch) are designed to deliver exceptional performance and durability, making them ideal for various applications.

We take pride in our commitment to quality, ensuring that all our sprockets meet the highest industry standards. Alongside our top-notch products, we offer excellent pre-sales and after-sales services to assist our customers at every step of their purchasing journey.

Additionally, we understand that every client has unique needs, which is why we provide non-standard customizations based on customer specifications. This flexibility allows us to cater to diverse requirements while maintaining our high-quality standards.

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 60 Roller Chain (3/4″ Pitch) is designed for durability and precision in various industrial applications. This sprocket allows for custom bore modifications, ensuring a perfect fit for your specific needs. GBC proudly offers high-quality Machinable Bore Sprockets in Australia.