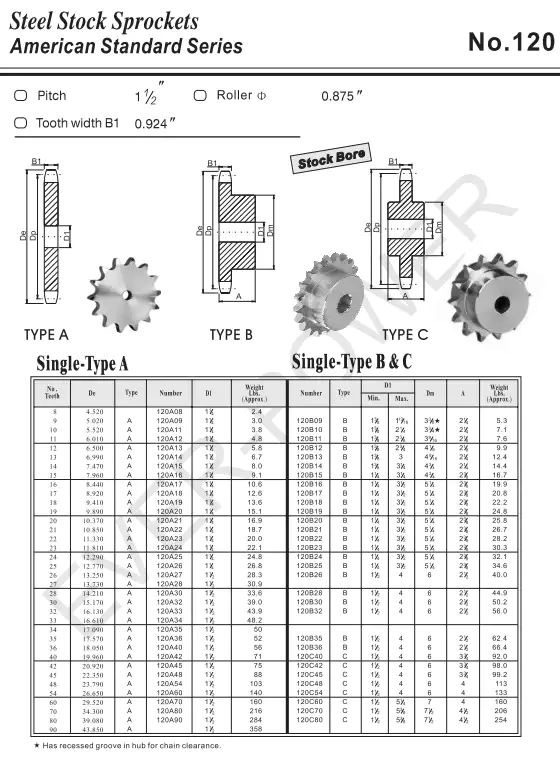

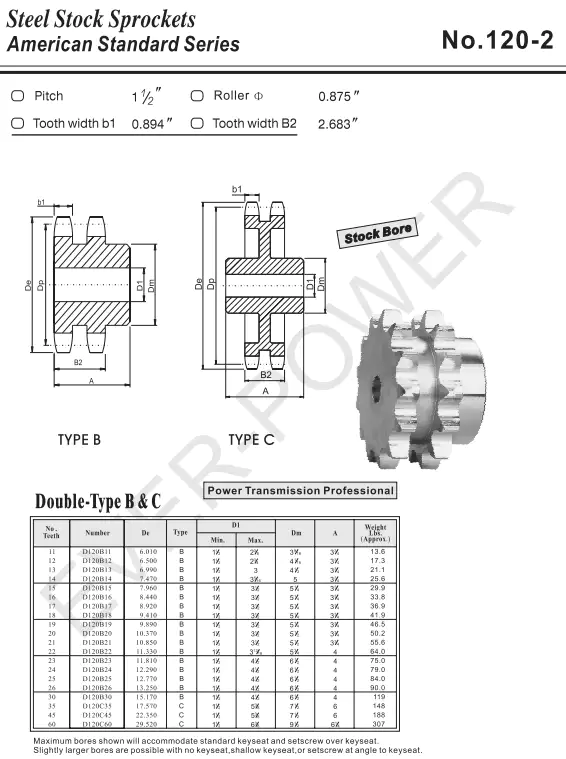

Machinable Bore Sprocket for ANSI 120 Roller Chain (1 1/2″ Pitch)

The Machinable Bore Sprocket for ANSI 120 Roller Chain is designed for precision and durability, featuring a 1 1/2″ pitch to ensure optimal performance in various applications. This sprocket can be easily machined to fit specific requirements, making it a versatile choice for engineers and manufacturers.

GBC offers high-quality Machinable Bore Sprockets in Australia, ensuring reliability and superior performance for your machinery needs.

Specifications of Machinable Bore Sprocket for ANSI 120 Roller Chain (1 1/2" Pitch)

A machinable bore sprocket is an essential component in numerous mechanical systems where precise motion transfer is critical. Designed to work seamlessly with ANSI 120 roller chains, this specific sprocket offers the advantage of a bore that can be customized to fit various shaft sizes. The Machinable Bore Sprocket for ANSI 120 Roller Chain (1 1/2" Pitch) is distinguished for its reliability, performance, and adaptability in various industrial applications.

Material and Manufacturing Process of Machinable Bore Sprocket for ANSI 120 Roller Chain

Our machinable bore sprockets are crafted from high-quality materials and are subjected to a meticulous manufacturing process to guarantee optimal performance:

- Material: We offer a variety of materials, including high carbon steel, alloy steel, or stainless steel tailored to specific application requirements, ensuring that each sprocket meets the necessary strength standards.

- Manufacturing Process: Our production methods include cutting, stamping, forging, machining (turning, milling, drilling), heat treatment (quenching, tempering), surface hardening, rust prevention treatment, and rigorous quality testing to ensure reliability.

Machinable Bore Sprockets Applications

Machinable Bore Sprockets for ANSI 120 Roller Chains are utilized across a wide array of industries and mechanical systems, such as:

- Heavy Machinery and Equipment: These sprockets are essential for driving heavy equipment, ensuring efficient power transfer and reliability.

- Food Processing and Packaging: In these sectors, components must meet strict hygiene and durability standards, making machinable bore sprockets invaluable.

- Chemical and Pharmaceutical: In environments requiring stringent compliance, these sprockets perform reliably under various conditions.

- Assembly Lines: The efficiency of assembly lines relies heavily on effective motion transfer, where these sprockets play a crucial role.

- Logistics and Warehousing: They are integral in driving conveyor systems that handle materials and products efficiently.

Maintenance and Troubleshooting

To ensure longevity and optimal operation of the sprockets, proper maintenance practices must be followed:

- Daily Inspection: It's essential to conduct regular checks for any signs of wear, damage, or misalignment to prevent operational failures.

- Cleaning: Keeping the sprocket free from dirt and debris is crucial, as buildup can lead to inefficiencies and system failures.

- Lubrication: Regularly applying the appropriate lubricants reduces friction and promotes smooth chain movement, enhancing performance.

- Adjustment and Calibration: Periodic adjustments to the chain tension and alignment ensure that the system operates smoothly and efficiently.

Common issues that may arise with sprockets include tooth skipping, breakage, wear, excessive noise, and chain detachment. Addressing these concerns may involve:

- Tooth Skipping: Misalignment or a worn-out chain should be inspected and replaced as needed to maintain performance.

- Breakage: Regular inspections for cracks or wear are vital, and replacement should occur if any issues are noted.

- Wear: Keeping track of wear patterns and replacing the sprocket upon reaching recommended tolerance levels is crucial.

- Excessive Noise: Ensuring proper lubrication and alignment can mitigate noise issues while checking for loose components.

- Chain Detachment: Verify chain tension and alignment regularly to avoid detachment, replacing any worn-out parts promptly.

Machinable Bore Sprockets Supplier - GBC

GBC is the sales agent for Ever-power Group in Australia, and we are proud to be one of the best sprocket suppliers in the country.

Our Machinable Bore Sprockets for ANSI 120 Roller Chain (1 1/2" Pitch) are designed to meet the highest standards of quality and durability. We utilize advanced manufacturing techniques and rigorous quality control processes to ensure that our sprockets perform reliably in various applications. Our dedicated team is committed to providing exceptional pre-sales and after-sales support, ensuring that our customers receive the guidance and assistance they need throughout their purchasing journey.

Additionally, we offer customized solutions to meet specific client requirements, allowing for non-standard designs that cater to unique operational needs. Trust GBC for all your sprocket needs!

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 120 Roller Chain is designed for precision and durability, featuring a 1 1/2″ pitch to ensure optimal performance in various applications. This sprocket can be easily machined to fit specific requirements, making it a versatile choice for engineers and manufacturers.

GBC offers high-quality Machinable Bore Sprockets in Australia, ensuring reliability and superior performance for your machinery needs.