40 Weld on Sprockets and Hubs

The 40 Weld on Sprockets and Hubs are essential components designed for durable and efficient power transmission. These sprockets can be seamlessly integrated with our V, W, X, and XX weld-on hubs, providing a reliable solution for various mechanical applications. Enhance your machinery’s performance with this robust combination.

Specifications of 40 Weld on Sprockets and Hubs

| No.Teeth | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 42 | 43 | 44 | 45 | 48 | 50 | 54 | 60 | 70 | 72 | 80 | 84 | 90 | |

| 40 | 1/2" Pitch | 40V12 | 40V13 | 40V14 | 40V15 | 40W16 | 40W17 | 40W18 | 40W19 | 40X20 | 40X21 | 40X22 | 40X23 | 40X24 | 40X25 | 40X26 | 40X27 | 40X28 | 40X29 | 40X30 | 40X31 | 40X32 | 40X33 | 40X34 | 40X35 | 40X36 | 40X37 | 40X38 | 40X39 | 40X40 | 40X42 | 40X43 | 40X44 | 40X45 | 40X48 | 40X50 | 40X54 | 40X60 | 40X70 | 40X72 | 40X80 | 40XB4 | 40X90 |

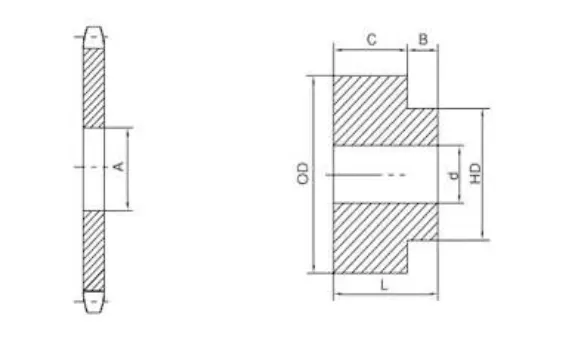

| Hub No. | Chain No. | d Min. | d Max. | OD | HD | L | B | C | App.WL. (Lbs.) | Hub No. | A | |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | V | 1-1/8 | |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | W | 1-5/8 | |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | X | 2 | |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | XX | 2 | |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | Y | 2-3/4 |

Applications and Industry Suitability for 40 Weld on Sprockets

The 40 Weld on Sprockets are versatile components widely used in various industries, including manufacturing, agriculture, and material handling. These sprockets and hubs are essential for power transmission in conveyor systems, agricultural machinery, and industrial equipment. In manufacturing, they ensure efficient movement of heavy loads, while in agriculture, they facilitate the operation of equipment like plowing and harvesting machines. A typical use case includes integrating these sprockets into a conveyor belt system, enhancing durability and performance. Businesses seeking reliable and robust solutions for their machinery will find these components perfectly suited to meet their needs.

Installation Guidelines for 40 Weld on Sprockets and Hubs

To ensure a successful installation of 40 Weld on Sprockets and Hubs, follow these steps:

- Preparation: Clean the surfaces to be welded, removing any rust or oil.

- Alignment: Carefully align the sprockets and hubs to prevent misalignment during welding.

- Preheating: Preheat the components to around 150°F (65°C) to reduce thermal shock.

- Welding Technique: Use the appropriate welding technique to ensure strong joints, maintaining a consistent speed and angle.

- Cooling: Allow the welded parts to cool slowly to prevent cracking.

Usage Guide for 40 Weld on Sprockets and Hubs

To ensure the longevity of your 40 Weld on Sprockets and Hubs, consider the following maintenance tips:

- Regularly inspect for signs of wear, such as cracks or deformation.

- Keep the sprockets clean and free from debris to prevent material buildup.

- Lubricate the hubs periodically to reduce friction and wear.

- Check alignment with the chain to avoid uneven wear.

- Replace any worn components promptly to maintain optimal performance.

Weld on Chain Sprockets Supplier

GBC is the Australian sales agent for Ever-power Group, and we are one of the top ten sprocket suppliers in Australia. We offer a wide range of products, including 40 weld-on chain sprockets and hubs, designed for durability and efficiency in various applications.

Our weld on sprockets are engineered with precision to ensure optimal performance and longevity. We pride ourselves on delivering high-quality sprockets that meet the diverse needs of our customers.

Our commitment to service is unparalleled, providing expert support and timely delivery to ensure customer satisfaction.

Additional information

| Edited | Sylvia |

|---|

The 40 Weld on Sprockets and Hubs are essential components designed for durable and efficient power transmission. These sprockets can be seamlessly integrated with our V, W, X, and XX weld-on hubs, providing a reliable solution for various mechanical applications. Enhance your machinery’s performance with this robust combination.