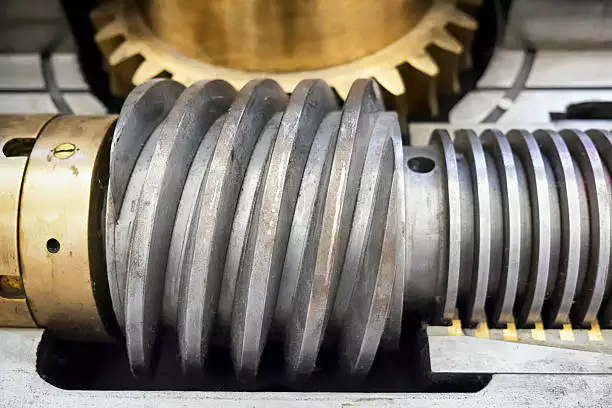

Bronze Worm Gear

The Bronze Worm Gear is a precision-engineered component designed for efficient power transmission. Made from high-quality bronze, this worm gear offers superior durability and resistance to wear. It functions in conjunction with a worm wheel to convert rotational motion at varying speeds and torque levels. The worm shaft is key to its operation, allowing smooth engagement with the worm screw for optimal performance. Overall, the Bronze Worm Gear is essential for reliable machinery and mechanical applications.

Specifications of Bronze Worm Gear

| Specification | Details |

|---|---|

| Material | Bronze |

| Gear Ratio | Up to 100:1 |

| Pitch Diameter | Varies (custom dimensions available) |

| Module | 1.0 - 5.0 |

| Efficiency | 70% - 90% |

| Operating Temperature | -40°C to 120°C |

| Applications | Automotive, Industrial Machinery, Robotics |

Features and Advantages of Bronze Worm Gear

The Bronze Worm Gear offers a range of features and benefits that make it a preferred choice for various mechanical applications:

- Durability: Made from high-quality bronze, the Worm Gear ensures long-lasting performance even under heavy loads.

- Efficiency: The design of the Worm Wheel and Worm Shaft allows for smooth operation with minimal friction, enhancing overall efficiency.

- Versatility: Suitable for different types of machinery, the Worm Screw can be utilized in various industrial applications.

- Low Noise: The unique geometry of the Bronze Worm Gear contributes to quieter operation compared to other gearing systems.

How the Bronze Worm Gear Works

The Bronze Worm Gear is a crucial component in mechanical systems, where it works in tandem with a worm wheel to reduce speed and increase torque. This setup features a worm shaft, which is a type of screw that meshes seamlessly with the worm wheel, allowing for efficient power transmission. The unique design of the worm gear ensures minimal backlash and smooth operation, making it ideal for applications requiring precise movement. With its durable materials, the Bronze Worm Gear is a reliable choice for various engineering needs.

Maintenance Tips for Bronze Worm Gear

- Regular Lubrication: To ensure the longevity of your Bronze Worm Gear, it is crucial to maintain proper lubrication. Lubricants help reduce friction between the Worm Gear, Worm Wheel, and Worm Shaft, minimizing wear and tear. Regularly check the lubricant’s condition and refill as necessary. Consider using high-quality grease specifically designed for worm gear applications. A well-lubricated system not only extends the life of the Worm Screw but also enhances overall performance by ensuring smoother operation.

- Visual Inspections: Conduct routine visual inspections of your Bronze Worm Gear assembly. Check for signs of wear on the Worm Gear and Worm Wheel, such as pitting, scoring, or unusual noise during operation. Early detection of wear can prevent more significant issues and costly repairs. Pay close attention to the Worm Shaft and ensure it is free from any damage or misalignment. Maintaining a schedule for these inspections will help you identify problems before they escalate.

- Proper Alignment: Misalignment can lead to premature failure of the Bronze Worm Gear. Ensure that the Worm Shaft is correctly aligned with the Worm Wheel to prevent excessive wear. Use alignment tools and techniques to check and adjust the positioning regularly. Misalignment can cause uneven load distribution, leading to accelerated wear on the Worm Gear and Worm Screw. A properly aligned system not only enhances performance but also extends the lifespan of the components.

- Temperature Control: Excessive heat can significantly affect the performance and lifespan of your Bronze Worm Gear. Monitor the operating temperature of your system and ensure it remains within the recommended range. Overheating may result from inadequate lubrication or overloading. Implementing cooling solutions, such as fans or heat sinks, can help manage temperatures effectively. Keeping the Worm Gear, Worm Wheel, and Worm Shaft cool will prevent thermal degradation and prolong their service life.

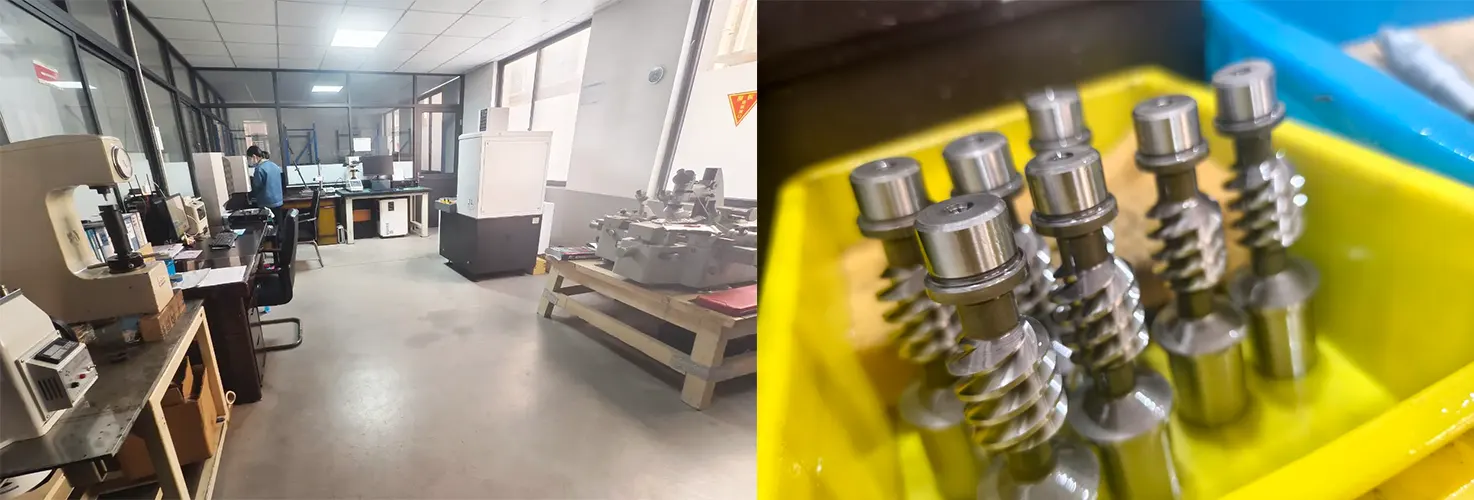

Worm Gear Manufacturer - GBC

Worm gears play a crucial role in various mechanical systems, providing efficient power transmission and enabling smooth operation in applications requiring high torque and low speed. Selecting a suitable supplier for worm gears is essential to ensure product quality and reliability, which directly impacts the performance of your machinery.

GBC is the Australian sales agent for Ever-power Group, positioning us as one of Australia's professional suppliers and manufacturers of worm gears. Our extensive experience in this field allows us to offer a wide range of high-quality products tailored to meet diverse industry needs.

Our bronze worm gears are known for their durability and excellent wear resistance, making them ideal for applications in various sectors, including automotive and industrial machinery. These gears provide reliable performance and longevity, ensuring optimal operation for our clients.

With a strong commitment to quality and customer satisfaction, our company prides itself on its manufacturing capabilities and exceptional service. We strive to meet our clients' needs effectively, providing comprehensive support and guidance throughout the purchasing process.

Additional information

| Edited | Sylvia |

|---|

The Bronze Worm Gear is a precision-engineered component designed for efficient power transmission. Made from high-quality bronze, this worm gear offers superior durability and resistance to wear. It functions in conjunction with a worm wheel to convert rotational motion at varying speeds and torque levels. The worm shaft is key to its operation, allowing smooth engagement with the worm screw for optimal performance. Overall, the Bronze Worm Gear is essential for reliable machinery and mechanical applications.