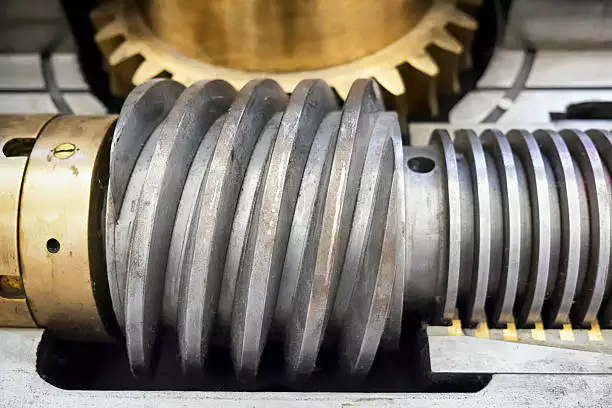

Cylindrical Worm Wheel

The Cylindrical Worm Wheel is a crucial component in mechanical systems, designed to work seamlessly with a Cylindrical Worm Gear. Made from high-quality materials such as steel or bronze, it ensures durability and efficient performance. This Worm Wheel converts rotational motion from a Worm Shaft into linear motion, making it ideal for applications requiring torque multiplication. The precise engineering of the Worm Screw and Worm Gear enhances the overall functionality, providing smooth operation and reliable power transmission in various machinery.

Specifications of Cylindrical Worm Wheel

| Parameter | Description |

|---|---|

| Material | Aluminum Alloy |

| Diameter | 50 mm |

| Pitch | 4 mm |

| Tooth Count | 20 |

| Load Capacity | 500 N |

| Efficiency | 90% |

| Operating Temperature | -20 to 80 °C |

Features and Advantages of the Cylindrical Worm Wheel

- High Efficiency: The Cylindrical Worm Wheel, paired with a Worm Gear, provides excellent efficiency in power transmission, minimizing energy loss.

- Compact Design: Its compact structure allows for space-saving installations, making it ideal for tight spaces.

- Load Distribution: The Worm Shaft and Worm Wheel work together to distribute loads evenly, enhancing durability and lifespan.

- Versatile Applications: Suitable for various industries, the Worm Screw and associated components offer flexibility in design and usage.

- Reduced Noise Levels: The design of the Worm Gear system ensures quieter operation compared to other gear types.

How the Cylindrical Worm Wheel Works

The Cylindrical Worm Wheel is a crucial component in mechanical systems, functioning in conjunction with the Cylindrical Worm Gear. This setup allows for efficient power transmission with minimal friction. The Worm Wheel engages with a Worm Shaft, creating smooth rotation through the Worm Screw. The unique design of the Worm Gear and Worm Wheel combination enables high torque output while maintaining a compact form. This makes the Cylindrical Worm Wheel ideal for various applications requiring reliable gear mechanisms.

Maintenance Tips for Cylindrical Worm Wheel

- Regular Inspections: Conducting frequent inspections of the Cylindrical Worm Wheel is crucial for identifying potential wear and tear. Check the Worm Gear and Worm Shaft for signs of damage or excessive wear. Look for any misalignment or unusual noises during operation, which could indicate a problem. By catching issues early, you can prevent further damage to components like the Worm Screw and ensure that the system operates smoothly. Regular maintenance can significantly extend the lifespan of the Worm Wheel, reducing the need for costly replacements and repairs.

- Proper Lubrication: Ensuring that the Worm Gear and Worm Wheel are adequately lubricated is essential for minimizing friction and wear. Use high-quality lubricant that is compatible with the materials of the Worm Shaft and Worm Screw. Regularly check the lubrication level and apply lubricant as needed to maintain optimal performance. Proper lubrication not only helps in reducing wear but also enhances the efficiency of the system. Neglecting this aspect can lead to overheating and premature failure of the Worm Wheel and other related components.

- Load Management: It is vital to operate the Cylindrical Worm Wheel within its specified load limits. Excessive loads can cause stress on the Worm Gear and Worm Shaft, leading to accelerated wear. Monitor the conditions under which the Worm Screw operates, ensuring that it is not subjected to unexpected loads. By adhering to the manufacturer's guidelines regarding load limits, you can significantly enhance the durability and longevity of the Worm Wheel. This proactive approach helps prevent costly downtimes and ensures reliable operation.

Worm Gear Manufacturer - GBC

Worm gears are crucial in various mechanical applications due to their ability to provide high torque while allowing for significant speed reduction. Choosing the right supplier for worm gears is essential to ensure reliability, efficiency, and durability in your machinery. GBC is proud to be the Australian sales agent for Ever-power Group, positioning us as one of Australia's leading suppliers and manufacturers of worm gears and worm wheels.

Our company specializes in providing high-quality Cylindrical Worm Wheels designed to meet the diverse needs of our clients. These products are engineered for precision and performance, making them ideal for a wide range of applications from industrial machinery to automation systems.

At GBC, we pride ourselves on our strength in product quality and our commitment to exceptional customer service. Our team is dedicated to providing tailored solutions to meet your specific requirements, ensuring that you receive the best products and support in the industry.

Additional information

| Edited | Sylvia |

|---|

The Cylindrical Worm Wheel is a crucial component in mechanical systems, designed to work seamlessly with a Cylindrical Worm Gear. Made from high-quality materials such as steel or bronze, it ensures durability and efficient performance. This Worm Wheel converts rotational motion from a Worm Shaft into linear motion, making it ideal for applications requiring torque multiplication. The precise engineering of the Worm Screw and Worm Gear enhances the overall functionality, providing smooth operation and reliable power transmission in various machinery.