Machinable Bore Sprocket for ANSI 50 Roller Chain (5/8″ Pitch)

The Machinable Bore Sprocket for ANSI 50 Roller Chain (5/8″ Pitch) is engineered for precision and durability, making it ideal for various mechanical applications. Its customizable bore allows for easy installation on different shaft sizes, ensuring optimal performance. GBC is committed to providing high-quality machined bore sprockets in Australia.

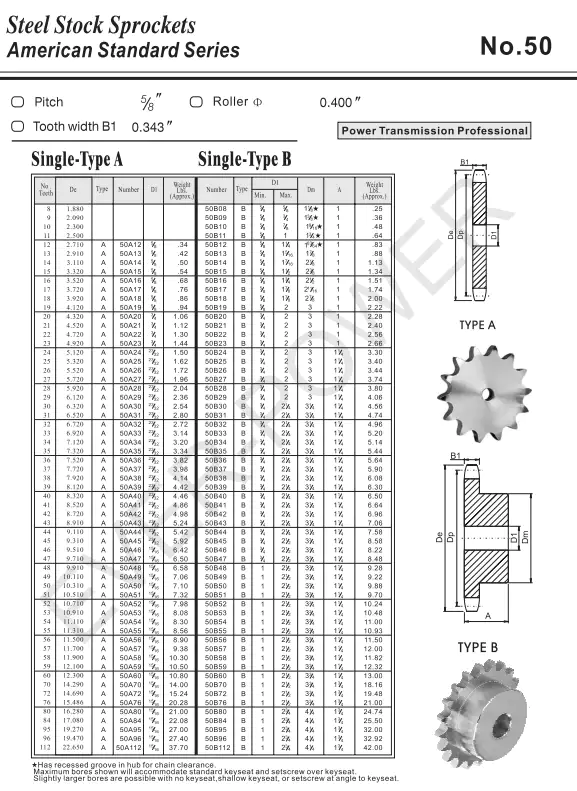

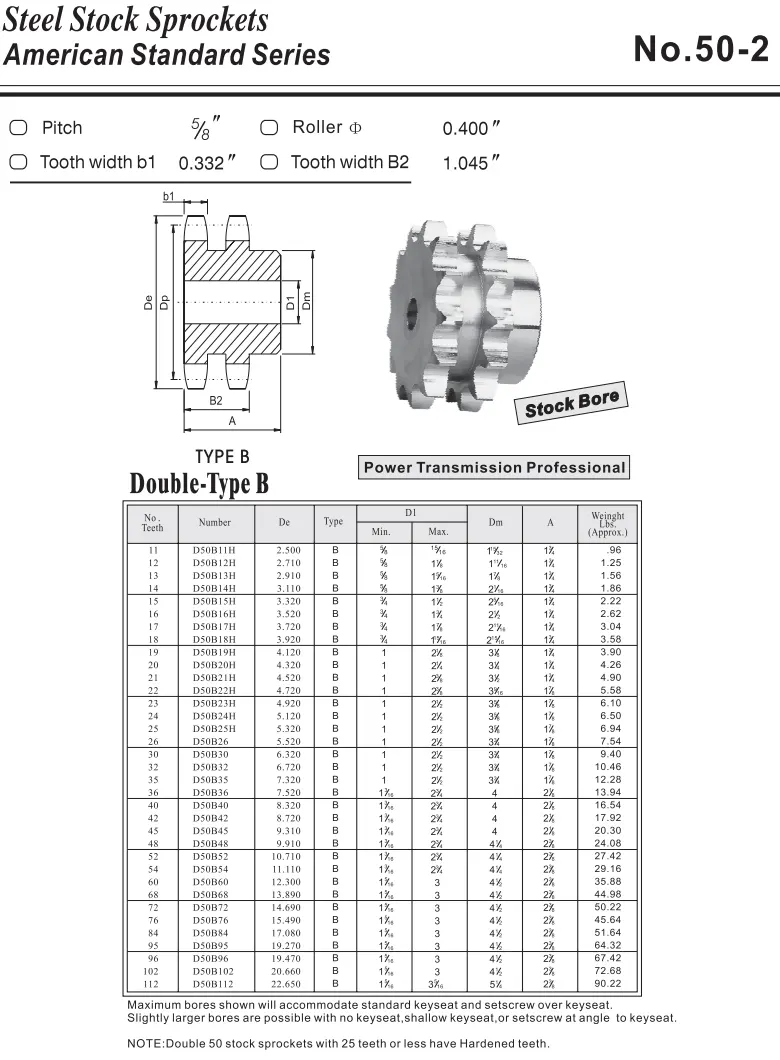

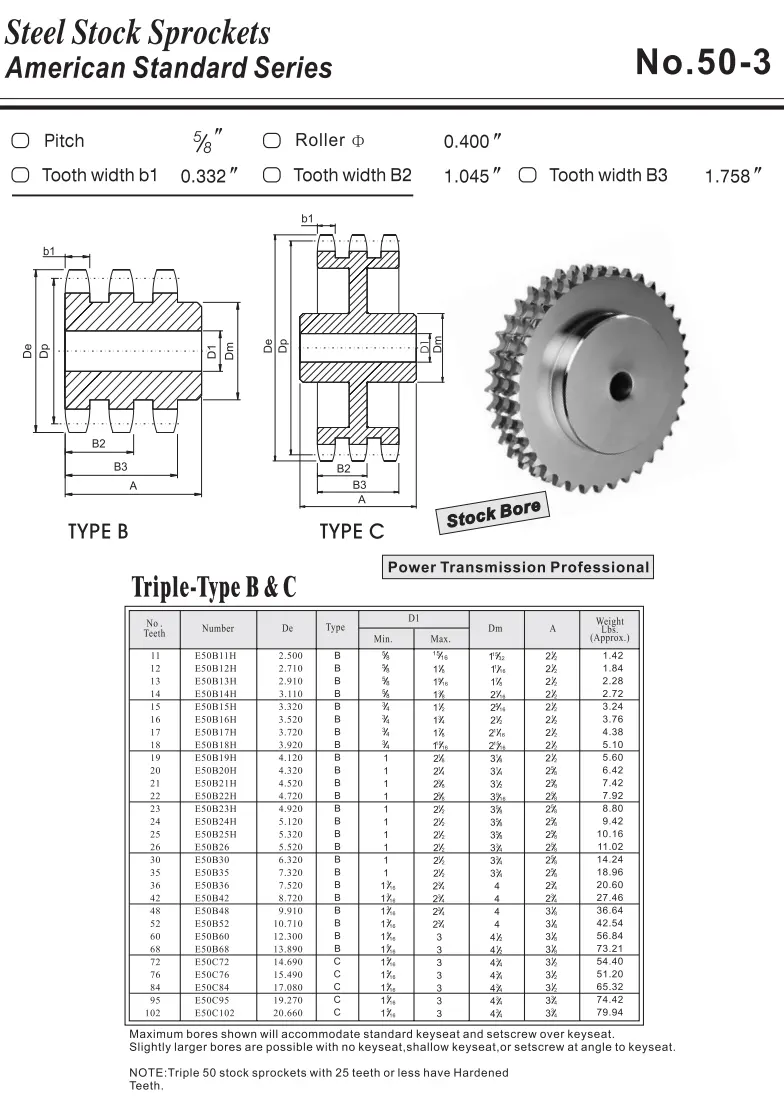

Specifications for Machinable Bore Sprocket for ANSI 50 Roller Chain (5/8" Pitch)

A machinable bore sprocket is a crucial component designed to interface with an ANSI 50 roller chain, which features a 5/8" pitch. This particular type of sprocket allows the bore to be customized to fit various shaft sizes, ensuring versatility in different applications. The Machinable Bore Sprocket for ANSI 50 Roller Chain is characterized by its durable construction, which effectively transmits power and motion through the interaction of its teeth with the chain. The adaptability of this sprocket makes it a preferred choice in various industries that require precision and reliability in power transmission.

Structure and Customization of 5/8" Chain Bore Sprocket

The fundamental structure of a sprocket consists of several key components: the hub, bore, teeth, and keyway. Customizing a sprocket involves careful consideration of several factors to ensure optimal performance for specific applications. These factors include:

- Material: The choice of material for the sprocket is crucial as it impacts durability and performance. Options range from high carbon steel for strength to stainless steel for corrosion resistance.

- Tooth profile: The design of the tooth profile must correspond to the type of chain being utilized, ensuring effective meshing and power transfer.

- Number of teeth: The total number of teeth on the sprocket influences the speed ratio and the ability to transmit torque efficiently.

- Dimensions: Accurate dimensions are essential to meet the specific design requirements of the machinery it will be used with.

- Bore size: The bore size must align with the shaft diameter of the connected equipment, allowing for a secure fit.

- Keyway size: It is important that the keyway size is compatible with the key used in the shaft to prevent slippage.

- Surface treatment: Various surface treatments can be applied to enhance durability, including hardening processes or protective coatings.

Materials and Processes Used in Our Sprockets

Our machinable bore sprockets are produced using high-quality materials and state-of-the-art manufacturing processes. These processes ensure that each sprocket meets the rigorous demands of various applications:

- Material: Depending on the specific requirements, we utilize high carbon steel, alloy steel, or stainless steel, chosen for their mechanical properties.

- Process: The manufacturing involves several steps, including cutting, stamping, forging, machining, heat treatment, surface hardening, and thorough quality inspection to guarantee reliability and performance.

5/8" Chain Bore Sprocket Applications

Machinable bore sprockets are versatile components that find applications across multiple industries. They are used in:

- Heavy machinery and equipment: These sprockets are integral to the operation of construction equipment, agricultural machinery, and mining vehicles, facilitating reliable power transmission.

- Food processing and packaging: In the food industry, sprockets are utilized in conveyor systems and packaging machinery, ensuring the efficient movement of goods.

- Chemical and pharmaceutical: They play a key role in reactors, mixers, and production equipment within chemical and pharmaceutical manufacturing processes.

- Assembly lines: In manufacturing environments, sprockets are crucial for the operation of assembly lines across various sectors, including automotive and electronics.

- Logistics and warehousing: They are used in conveyor systems and material handling equipment, streamlining operations in logistics and warehouse settings.

5/8" Chain Bore Sprocket Maintenance and Troubleshooting

To maintain the efficiency and longevity of machinable bore sprockets, regular maintenance and troubleshooting are essential components of proper care. Here are some effective maintenance tips:

- Daily inspection: Conduct regular checks for signs of wear, damage, and proper alignment to catch potential issues early.

- Cleaning: Keeping the sprocket free from debris and contaminants is vital for its continued performance.

- Lubrication: Apply lubricant consistently to minimize friction and prevent wear, enhancing the lifespan of the sprocket.

- Adjustment and calibration: Ensure the sprocket is correctly aligned and tensioned to prevent operational problems.

Common issues that can arise with sprockets include:

- Skipping teeth: This problem may result from worn or damaged teeth or improper tensioning, leading to ineffective power transmission.

- Breakage: Overloading, material fatigue, or defects can cause sprocket breakage, necessitating immediate attention.

- Wear: Abrasive materials or inadequate lubrication can contribute to premature wear of the sprocket.

- Noise: Excessive noise can indicate misalignment, loose chains, or worn teeth, requiring prompt investigation.

- Chain fall off: This can occur due to improper installation, insufficient tension, or worn teeth, which should be addressed to avoid further complications.

Machinable Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are recognized as one of the best sprocket suppliers in Australia. Our expertise extends to a wide range of chain products, including the Machinable Bore Sprocket for ANSI 50 Roller Chain (5/8" Pitch). Our sprockets are fabricated with the highest quality materials, ensuring durability and reliability for various applications.

At GBC, we pride ourselves on our exceptional pre-sale and after-sale services. Our knowledgeable team is always ready to assist customers in selecting the right sprocket for their needs, and we provide ongoing support to ensure satisfaction throughout the product's lifecycle. Additionally, we offer custom non-standard sprocket solutions tailored to meet specific customer requirements, helping businesses optimize their operations.

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 50 Roller Chain (5/8″ Pitch) is engineered for precision and durability, making it ideal for various mechanical applications. Its customizable bore allows for easy installation on different shaft sizes, ensuring optimal performance. GBC is committed to providing high-quality machined bore sprockets in Australia.