Planetary Slew Drive Gearbox for Automated Assembly Lines

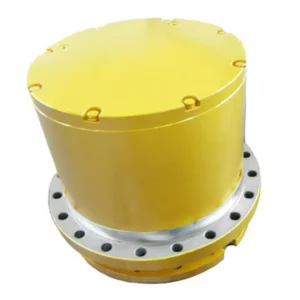

The Planetary Slew Drive Gearbox is essential for automated assembly lines, providing precise movement and positioning. Its compact design allows for smooth rotation and high torque transmission, ensuring reliable operation in fast-paced environments. This gearbox enhances productivity by facilitating accurate alignment and seamless transitions between assembly tasks, ultimately improving efficiency and reducing downtime in manufacturing processes.

Planetary Slew Drive Gearbox for Automated Assembly Lines

The Planetary Slew Drive Gearbox offers exceptional torque and precision, making it ideal for automated assembly lines. Its compact design ensures efficient space utilization while providing reliable performance under varying loads.

| Specification | Details |

|---|---|

| Output torque range | 1000–180000 N.m |

| Gear ratios | i = 3.3–3000 |

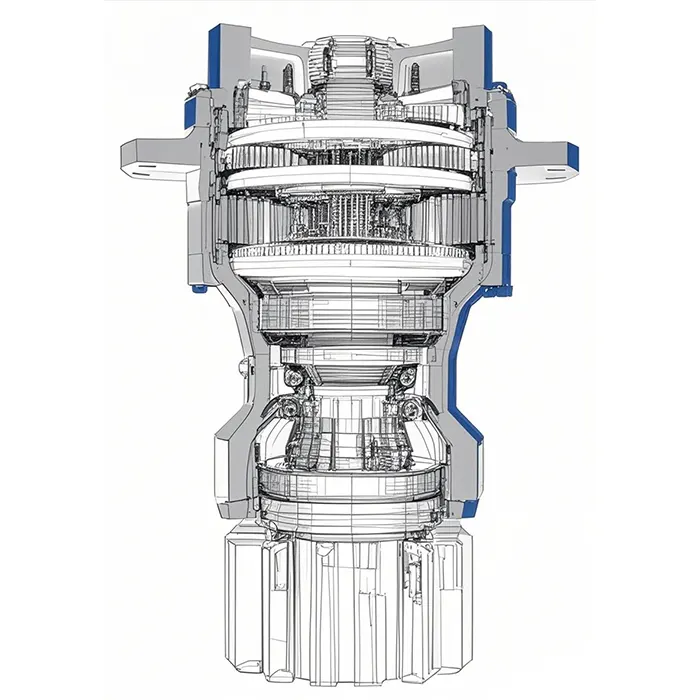

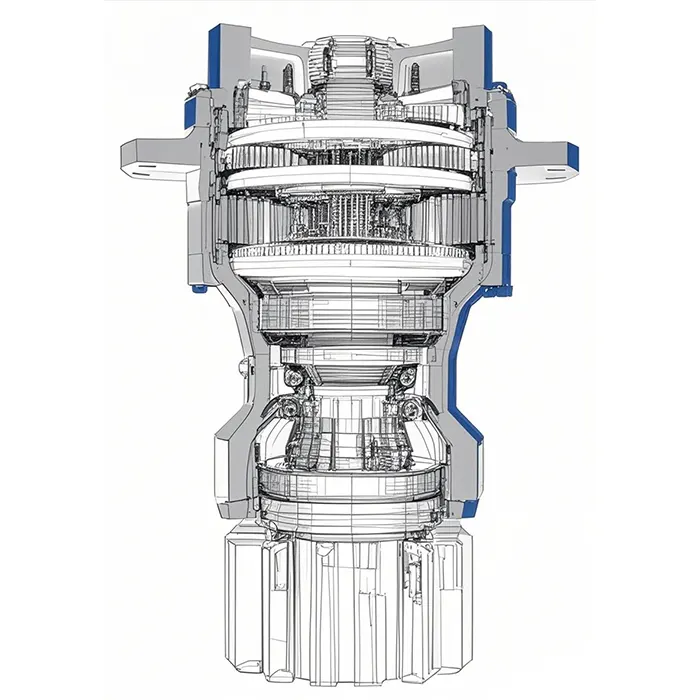

| Support | Slew support (with flange mounted) |

| Output shaft | Splined or with integral pinion; output shafts supported by heavy duty capacity bearings |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors, IEC electric motors |

| Hydraulic motor options | Pressure relief valve, over-center valve, parking brake |

| Electric brake | DC and AC type |

| Hydraulic brake | Hydraulically released parking brake |

| 700L Series Slewing Drive | |||||

| Type | Max. torque (N.m) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP700L | 1000 | 1200 | 3.38-32 | 3500 | 50-400 |

| EP701L | 1800 | 2400 | 3.38-32 | 3500 | 50-400 |

| EP703AL | 2500 | 3500 | 12-175 | 3500 | 50-400 |

| EP705AL | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP705L | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP706AL | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP706L | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP707AL | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP707L | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP709AL | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP709L | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP711AL | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP711L | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP713L | 40000 | 55000 | 50-276 | 2500 | 400-1000 |

| EP715L3 | 70000 | 80000 | 54-242 | 2500 | 850-3200 |

| 700S Series Slewing Drive | |||||

| Type | Max. torque (N.m ) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP706S | 7700 | 10000 | 20-106 | 3500 | 400-1000 |

| EP707S | 10500 | 16500 | 25-134 | 3500 | 400-1000 |

| EP709S | 16000 | 26000 | 20-144 | 3500 | 400-1000 |

| EP710S | 18000 | 29000 | 36-52 | 3500 | 400-1000 |

| EP710BS | 23000 | 35000 | 110-176 | 3500 | 400-1000 |

| EP710DS | 27800 | 48500 | 32-181 | 3500 | 400-1000 |

| EP714S | 45000 | 68300 | 63-187 | 3000 | 600-2000 |

| EP715S | 65000 | 93300 | 63-212 | 3000 | 600-2000 |

| EP716S | 120000 | - | 63-1500 | 2500 | 600-2000 |

| EP717S | 180000 | - | 63-1500 | 2000 | 600-2000 |

Planetary Slew Drive Gearbox VS Worm Gearbox

- Efficiency: Planetary gearboxes typically offer higher efficiency, reducing energy loss compared to worm gearboxes.

- Torque Capacity: Planetary slewing drives provide greater torque capacity, making them suitable for heavy-duty applications.

- Size and Weight: Planetary gearboxes are often more compact and lighter, optimizing space in automated assembly lines.

- Backlash: Planetary systems generally have lower backlash, enhancing precision in positioning tasks.

Selection of Planetary Slew Drive Gearbox

Choosing the right model and gear ratio for a Planetary Slew Drive Gearbox involves several critical factors. Firstly, you must consider the load torque, as it directly influences the gearbox's performance and longevity. Additionally, the input speed is vital; ensuring compatibility with your system enhances operational efficiency. The working environment, including temperature and humidity, also plays a crucial role in selecting a durable unit. Furthermore, available installation space must be assessed to ensure a proper fit. We offer a variety of models and customizable gear ratios to meet the unique demands of your automated assembly line.

Installations

To install the Planetary Slew Drive Gearbox for Automated Assembly Lines, follow these steps:

- Ensure the installation area is clean and free from debris.

- Align the gearbox with the mounting surface using the provided bolts.

- Securely tighten the bolts to prevent any movement during operation.

- Connect the power source to the gearbox following the manufacturer's specifications.

- Conduct a functional test to verify proper operation.

Slewing Drive Planetary Gearbox Manufacturer

GBC is the Australian sales agent for the Ever-power Group, specializing in high-quality slewing drive planetary gearboxes. Our Planetary Slew Drive Gearbox is designed specifically for automated assembly lines, ensuring efficient and reliable operation. We pride ourselves on providing excellent customer service, with a comprehensive after-sales support system that guarantees satisfaction and peace of mind.

We encourage all customers to customize their gearboxes to fit their specific needs and to reach out for pricing inquiries. Your satisfaction is our priority, and we look forward to supporting your projects with our top-notch products and services.

Additional information

| Edited by | Sylvia |

|---|

The Planetary Slew Drive Gearbox is essential for automated assembly lines, providing precise movement and positioning. Its compact design allows for smooth rotation and high torque transmission, ensuring reliable operation in fast-paced environments. This gearbox enhances productivity by facilitating accurate alignment and seamless transitions between assembly tasks, ultimately improving efficiency and reducing downtime in manufacturing processes.