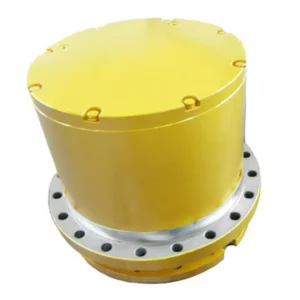

Planetary Slew Drive Gearbox for Tunnel Boring Machines

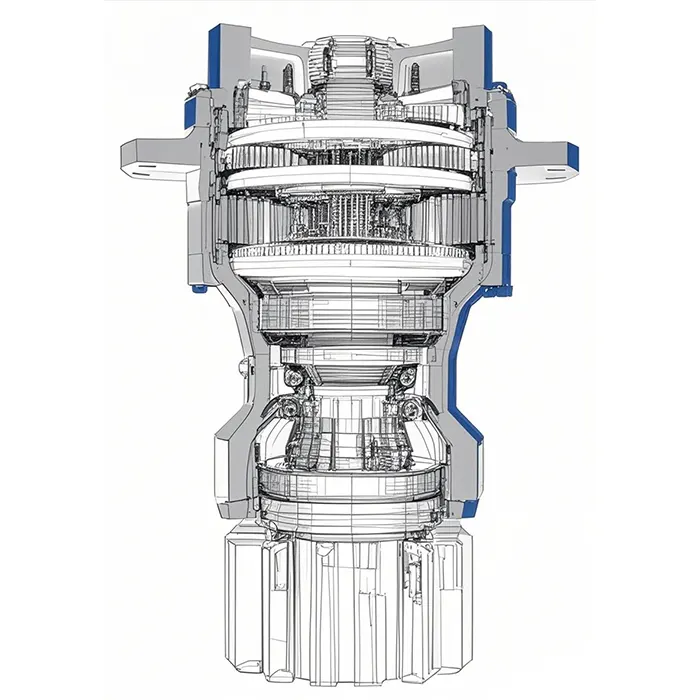

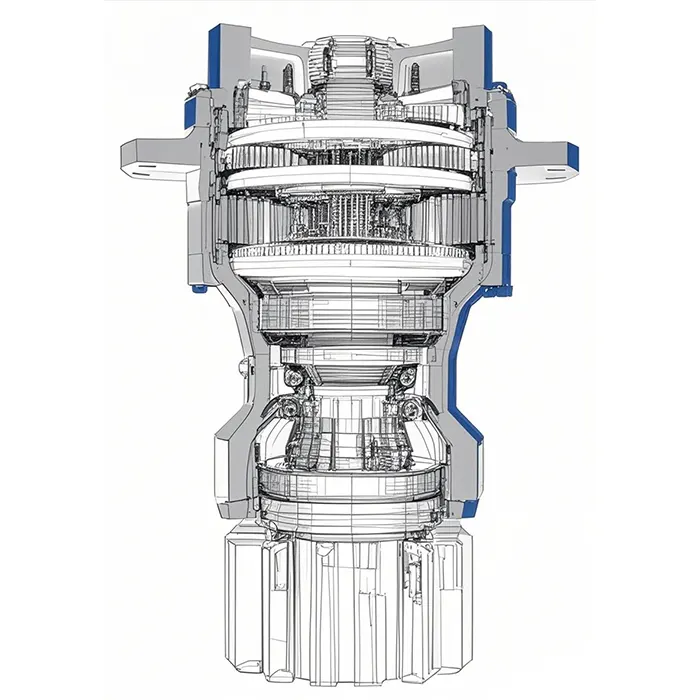

The Planetary Slew Drive Gearbox for Tunnel Boring Machines is designed to provide precise control and stability during the tunneling process. Its robust construction ensures reliable performance under the extreme conditions of underground operations. By facilitating smooth rotation and positioning of the boring head, this gearbox enhances efficiency, thereby minimizing downtime and maximizing productivity in tunnel excavation projects.

Planetary Slew Drive Gearbox for Tunnel Boring Machines

The Planetary Slew Drive Gearbox is designed to provide exceptional torque and precision for tunnel boring machines, ensuring smooth operation in challenging underground environments. Its compact design and high-efficiency performance enable enhanced productivity while minimizing downtime and maintenance costs.

| Specification | Details |

|---|---|

| Output torque range | 1000–180000 N.m |

| Gear ratios | i = 3.3–3000 |

| Support | Slew support (with flange mounted) |

| Output shaft | Splined or with integral pinion; output shafts supported by heavy duty capacity bearings |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors, IEC electric motors |

| Hydraulic motor options | Pressure relief valve, over-center valve, parking brake |

| Electric brake | DC and AC type |

| Hydraulic brake | Hydraulically released parking brake |

| 700L Series Slewing Drive | |||||

| Type | Max. torque (N.m) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP700L | 1000 | 1200 | 3.38-32 | 3500 | 50-400 |

| EP701L | 1800 | 2400 | 3.38-32 | 3500 | 50-400 |

| EP703AL | 2500 | 3500 | 12-175 | 3500 | 50-400 |

| EP705AL | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP705L | 5000 | 6500 | 12-175 | 3500 | 50-400 |

| EP706AL | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP706L | 7700 | 12000 | 13-143 | 3500 | 50-1000 |

| EP707AL | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP707L | 10500 | 16500 | 13-256 | 3500 | 50-1000 |

| EP709AL | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP709L | 16000 | 26000 | 13-256 | 3500 | 50-1000 |

| EP711AL | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP711L | 32000 | 45000 | 14-223 | 2500 | 400-3200 |

| EP713L | 40000 | 55000 | 50-276 | 2500 | 400-1000 |

| EP715L3 | 70000 | 80000 | 54-242 | 2500 | 850-3200 |

| 700S Series Slewing Drive | |||||

| Type | Max. torque (N.m ) | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) | |

| Excavator | Crane | ||||

| EP706S | 7700 | 10000 | 20-106 | 3500 | 400-1000 |

| EP707S | 10500 | 16500 | 25-134 | 3500 | 400-1000 |

| EP709S | 16000 | 26000 | 20-144 | 3500 | 400-1000 |

| EP710S | 18000 | 29000 | 36-52 | 3500 | 400-1000 |

| EP710BS | 23000 | 35000 | 110-176 | 3500 | 400-1000 |

| EP710DS | 27800 | 48500 | 32-181 | 3500 | 400-1000 |

| EP714S | 45000 | 68300 | 63-187 | 3000 | 600-2000 |

| EP715S | 65000 | 93300 | 63-212 | 3000 | 600-2000 |

| EP716S | 120000 | - | 63-1500 | 2500 | 600-2000 |

| EP717S | 180000 | - | 63-1500 | 2000 | 600-2000 |

Planetary Gearbox Slewing Drive VS Worm Gearbox

1. Efficiency: Planetary gearboxes offer higher efficiency compared to worm gearboxes, reducing energy loss.

2. Load Capacity: Planetary drives can handle heavier loads due to their distributed load design.

3. Compact Design: The planetary slewing drive has a more compact size, making it suitable for tight spaces in tunnel boring machines.

4. Backlash: Planetary gearboxes provide lower backlash, ensuring better precision in movements.

Selection of Planetary Slew Drive Gearbox for Tunnel Boring Machines

Choosing the right model and gear ratio for a planetary slew drive gearbox involves several crucial considerations. First, assess the load torque requirements to ensure the gearbox can handle the operational demands. Next, evaluate the input speed to optimize performance. It's also essential to consider the working environment, including temperature and humidity, which can affect gearbox efficiency. Additionally, the available installation space should be taken into account to ensure a proper fit. We offer a wide range of models and support custom gear ratios to meet your specific needs, ensuring optimal performance for your tunnel boring machines.

Installations

To install the Planetary Slew Drive Gearbox for Tunnel Boring Machines, follow these steps:

- Ensure all components are clean and free from debris.

- Align the gearbox with the borehole structure accurately.

- Securely fasten the gearbox using appropriate bolts and tools.

- Check that all connections are tight and functioning correctly.

- Perform a test run to verify proper operation.

Slewing Drive Planetary Gearbox Manufacturer

GBC is the sales agent for Ever-power Group in Australia, specializing in high-quality slewing drive planetary gearboxes. Our flagship product, the Planetary Slew Drive Gearbox for Tunnel Boring Machines, is designed to deliver exceptional performance and reliability in demanding applications. We pride ourselves on providing outstanding service, ensuring our customers receive the best possible experience. Our comprehensive after-sales support system guarantees that any issues are addressed promptly and efficiently.

We encourage all customers to customize their solutions according to their specific needs and request a quote today for the best service in the industry.

Additional information

| Edited by | Sylvia |

|---|

The Planetary Slew Drive Gearbox for Tunnel Boring Machines is designed to provide precise control and stability during the tunneling process. Its robust construction ensures reliable performance under the extreme conditions of underground operations. By facilitating smooth rotation and positioning of the boring head, this gearbox enhances efficiency, thereby minimizing downtime and maximizing productivity in tunnel excavation projects.