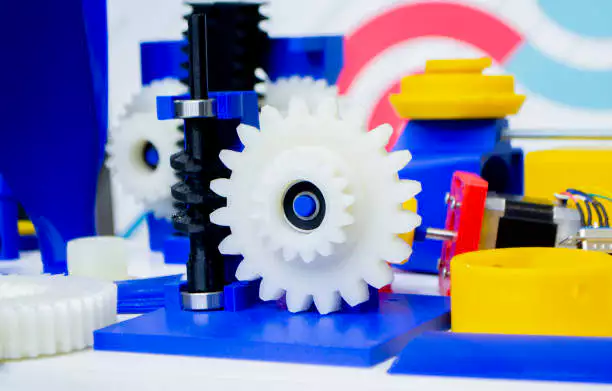

Plastic Worm Gears

Plastic worm gears are essential components used in various mechanical systems, designed to transmit motion and force efficiently. Made from durable plastic, these plastic worm gears are lightweight yet robust, making them ideal for applications where corrosion resistance is vital. The plastic worm drive ensures smooth operation, while the plastic worm gear set provides versatile configurations to meet different design requirements. Additionally, small plastic worm gears are perfect for compact spaces, allowing for precise control in devices. Overall, plastic worm wheels enhance the functionality and reliability of many mechanisms.

Specifications of Plastic Worm Gears

| Type | Worm |

|---|---|

| Module | M0.2 - M2.0 |

| Material | Polyacetal (POM) / Nylon |

| Bore | Ø1.40mm/ Ø1.90mm |

| Outer Diameter | Ø4.0mm/ Ø5.0mm/ Ø6.0mm (Flexible) |

| Length | 6.0mm/ 8.5mm/ 10.0mm (Flexible) |

| Item | M0.4*30T Gear+Worm |

|---|---|

| Material | TEPCON_M90-10 |

| Module | M0.4 |

| No. of Teeth | 30T / 1T |

| Weight | 0.75g / pcs |

| Application | IP Camera, monitor, etc. |

| Item | M0.4 RH Worm |

|---|---|

| Material | TEPCON_M90-10 |

| Module | M0.4 |

| No. of Teeth | 1T (RH) |

| Weight | 0.22g / pcs |

| Application | Applies in the gearbox to adjust the automotive rearview mirror. |

| Item | Gear Screw & Screw Nut |

|---|---|

| Material | ODM |

| Module | ODM |

| No. of Teeth | ODM |

| Weight | ODM |

| Application | Applies in the gearbox to adjust the water valve. |

Features and Advantages of Plastic Worm Gears

- Durability: Plastic worm gears are designed to withstand wear and tear, making them ideal for various applications.

- Lightweight: The small plastic worm gears are lightweight, reducing overall machinery weight and enhancing efficiency.

- Corrosion Resistance: Being made of plastic, these gears resist corrosion, ensuring longevity even in harsh environments.

- Low Noise Operation: Plastic worm drive systems operate quietly, making them suitable for noise-sensitive applications.

- Versatility: The plastic worm gear set can be used in various industries, including automotive, robotics, and more.

How Plastic Worm Gears Work

Plastic worm gears operate using a unique mechanism where a worm, or a screw-like gear, meshes with a worm wheel. This setup allows for high torque transmission and precise motion control. The plastic worm gear is lightweight, making it ideal for various applications. A plastic worm drive efficiently transfers motion with minimal backlash. Various configurations, including plastic worm gear sets and small plastic worm gears, enhance versatility and performance in machinery.

Maintenance Tips for Plastic Worm Gears

- Regular Inspection for Wear and Tear: To prolong the lifespan of your plastic worm gears, it's crucial to conduct regular inspections for signs of wear and tear. Examine both the plastic worm gear and the plastic worm wheel for any signs of distortion or damage. Look for cracks, chips, or irregularities in the gear teeth that could affect performance. If you notice any significant wear, it's advisable to replace the plastic worm gear set. Maintaining a proactive approach can help you identify potential issues before they lead to catastrophic failures in your plastic worm drive system.

- Lubrication: Adequate lubrication is essential for the smooth operation of small plastic worm gears. Using a suitable lubricant can minimize friction, reducing wear and extending the life of the gears. Choose a lubricant that is compatible with plastic materials to avoid degrading the gear components. Apply lubricant evenly on the plastic worm gear and the associated plastic worm wheel, ensuring that all moving parts are adequately coated. Remember that over-lubrication can also lead to issues, so follow the manufacturer's recommendations for the right amount of lubricant to use.

- Temperature Control: Plastic worm gears can be sensitive to extreme temperatures, which may lead to deformation and reduced effectiveness. It's important to monitor the operating temperature where the worm drive is used. Avoid exposing your plastic worm gear and worm wheel to high heat or direct sunlight for extended periods. If your application involves high temperatures, consider using heat-resistant plastic worm gears designed to withstand such conditions. Implementing temperature control measures can greatly enhance the durability of your gear system.

Worm Gear Manufacturer - GBC

Worm gears play a crucial role in various mechanical systems, providing efficient power transmission and enabling precise speed reduction. Choosing the right supplier for worm gears is essential to ensure reliability, quality, and performance. GBC, as a sales agent for Ever-power Group in Australia, stands out as one of the leading suppliers and manufacturers of worm gears in the region.

Our company specializes in producing high-quality plastic worm gears, designed for durability and optimal performance in various applications. These gears are lightweight, resistant to wear, and suitable for environments where noise reduction is important.

With a strong commitment to excellence, GBC boasts advanced manufacturing capabilities and a dedicated team ready to meet your specific requirements. Our focus on customer service ensures that we provide tailored solutions and support throughout the purchasing process.

Additional information

| Edited | Sylvia |

|---|

Plastic worm gears are essential components used in various mechanical systems, designed to transmit motion and force efficiently. Made from durable plastic, these plastic worm gears are lightweight yet robust, making them ideal for applications where corrosion resistance is vital. The plastic worm drive ensures smooth operation, while the plastic worm gear set provides versatile configurations to meet different design requirements. Additionally, small plastic worm gears are perfect for compact spaces, allowing for precise control in devices. Overall, plastic worm wheels enhance the functionality and reliability of many mechanisms.