Plate Wheel Sprocket 06B-1-2-3

The Plate Wheel Sprocket 06B-1-2-3 is designed for durability and efficiency in various mechanical applications. With its robust construction and precise engineering, it ensures optimal performance and longevity. Ideal for industrial use, this sprocket provides reliable power transmission. GBC proudly offers high-quality Plate Wheel Sprockets in Australia.

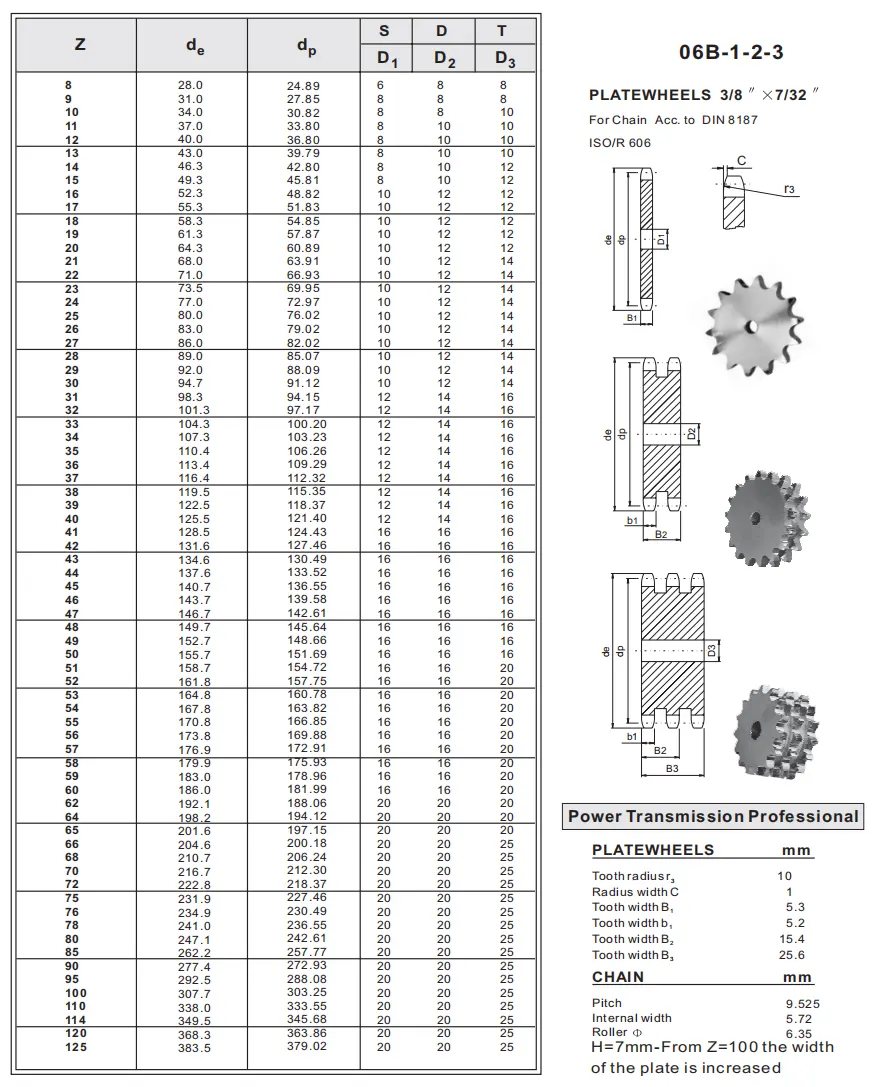

Specifications of Plate Wheel Sprocket 06B-1-2-3

Plate Wheel Sprocket 06B-1-2-3 is an essential component in power transmission systems, specifically designed to work seamlessly with plate chains. This type of sprocket is integral to the operation of various industrial machinery. The sprocket features a unique design where its teeth are perfectly shaped to interface with the plate chain, ensuring efficient power transfer. The plate chain itself comprises interlinked plates that glide smoothly over the sprocket teeth, making this combination fundamental for reliable performance in multiple applications.

Types of Plate Wheels

Plate wheels are available in several types, including single-row, double-row, and multi-row configurations. The choice of which plate wheel to implement in a power transmission system is guided by the specific requirements of the application, such as load capacity and space constraints. Each type has its unique advantages, optimizing the system's overall efficiency and effectiveness.

Product Features of Plate Wheel Sprocket

Our Plate Wheel Sprocket is manufactured from high-quality materials that ensure exceptional corrosion resistance, wear resistance, strength, and toughness. These features are crucial for longevity and performance in demanding environments. Additionally, the sprocket¡¯s design incorporates lightweight construction, precision manufacturing techniques, and specialized surface treatments that enhance its performance capabilities.

Material Advantages

The materials used in our Plate Wheel Sprocket include stainless steel, carbon steel, and alloy steel, each chosen for their unique properties that confer superior corrosion resistance, wear resistance, strength, and toughness. This careful selection of materials not only extends the life of the sprocket but also ensures reliable operation under various conditions, making it suitable for a wide range of industrial applications.

Design Features

Our Plate Wheel Sprocket employs a design focused on lightweight construction and precision manufacturing. The incorporation of advanced manufacturing technologies ensures high accuracy, durability, and reliability. Surface treatments further improve the sprocket's resistance to wear and environmental factors, enhancing its overall performance in demanding applications.

Our Services

We pride ourselves on offering a comprehensive range of services tailored to meet customer needs. These include customized products, assistance with material selection, surface treatments, heat treatments, and personalized packaging solutions.

Customized Products

Our team is dedicated to creating custom Plate Wheel Sprockets that align with your specific requirements. We work closely with clients to develop solutions that precisely meet the operational demands of their applications, ensuring optimal performance and reliability.

Material Selection

We provide an extensive selection of materials for our Plate Wheel Sprockets, including carbon steel, stainless steel, and alloy steel. Our experts are available to guide you in choosing the most suitable material for your unique application, ensuring that it meets both performance and budgetary needs.

Surface Treatment

To enhance corrosion resistance and wear resistance, we offer various surface treatment options. These treatments, including black oxide, zinc plating, and nickel plating, are designed to protect the sprocket and extend its service life, making it more resilient in harsh operating conditions.

Heat Treatment

Our Plate Wheel Sprockets can undergo heat treatment processes that improve their strength and toughness. Techniques such as quenching and tempering are applied based on the specific needs of the application, ensuring that the sprockets maintain their integrity under stress.

Customized Packaging

We also offer customized packaging solutions for your Plate Wheel Sprockets, ensuring they arrive in pristine condition. By using high-quality materials for packaging, we safeguard your products during transit, providing peace of mind.

Chainwheel Processing Flow

The processing of our chainwheels follows a meticulous flow that includes forging, machining, hobbing, teeth heating, quenching treatment, surface treatment, rust-proof treatment, quality inspection, packing, and shipping.

Forging

We begin the production process with forging, which shapes the raw material into the desired form. This initial step is crucial in establishing the foundational integrity and strength of the sprocket.

Machining

Advanced machining techniques are employed to achieve the necessary accuracy and precision during manufacturing. This stage plays a significant role in ensuring that the dimensions of the sprocket meet stringent specifications.

Hobbing

Through hobbing, we cut the sprocket teeth to attain their specific shapes and profiles. This process is vital for creating the intricate details that allow for optimal engagement with plate chains.

Teeth Heating

The sprocket teeth undergo heating to bolster their strength and overall durability. This heating process is essential for enhancing performance and ensuring the sprocket can handle demanding loads.

Quenching Treatment

We implement quenching treatments to harden the teeth of the sprocket, significantly improving their wear resistance. This treatment is a critical step to ensure that the sprocket can withstand the rigors of continuous operation.

Surface Treatment

Surface treatments are applied to enhance the sprocket's resistance to corrosion and wear. By improving these properties, we ensure that the sprocket maintains its functionality over time.

Rust-Proof Treatment

A rust-proof treatment is applied to safeguard the sprocket against rust and corrosion, protecting it from environmental factors that could compromise its integrity and performance.

Quality Inspection

Quality inspections are conducted to verify that each sprocket meets our high standards. Rigorous testing ensures that only top-quality products are delivered to our customers.

Packing and Shipping

Finally, we package the sprockets meticulously to ensure they arrive in perfect condition. Our shipping methods are designed to prevent any damage during transit, guaranteeing customer satisfaction.

Maintenance of Plate Wheels

To ensure the longevity and optimal performance of Plate Wheels, proper maintenance is crucial. Regular maintenance procedures should include daily inspections, cleaning, lubrication, and timely replacement of worn components.

Daily Inspection

Daily inspections are vital for identifying any signs of wear or damage in the Plate Wheels. Monitoring their condition closely helps prevent unexpected failures and prolongs the lifespan of the entire power transmission system.

Cleaning

Regular cleaning of the Plate Wheels is essential to maintain smooth operation. Using mild soap and water for cleaning helps remove debris and contaminants that may hinder performance, ensuring that they operate efficiently.

Lubrication

Lubrication is a necessary practice to minimize friction and wear between the Plate Wheels and the plate chain. Applying the right lubricant at regular intervals greatly enhances the efficiency of the system and reduces the likelihood of premature wear.

Replacement

It is imperative to replace Plate Wheels at the first sign of wear or damage. Immediate replacement helps avoid further damage to the power transmission system and ensures continued operational efficiency.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, and we are one of the top ten gear suppliers in Australia. Our extensive range of gear products includes the Plate Wheel Sprocket 06B-1-2-3, which is designed for optimal performance and durability. As a supplier, we pride ourselves on the diversity of our gear offerings, catering to various industries and application needs, while ensuring that our customers receive exceptional service.

In addition to standard plate wheel sprockets, we also specialize in custom non-standard solutions tailored to meet specific client requirements. We encourage all customers to reach out with their designs or samples, allowing us to provide personalized products that fit their unique needs.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket 06B-1-2-3 is designed for durability and efficiency in various mechanical applications. With its robust construction and precise engineering, it ensures optimal performance and longevity. Ideal for industrial use, this sprocket provides reliable power transmission. GBC proudly offers high-quality Plate Wheel Sprockets in Australia.