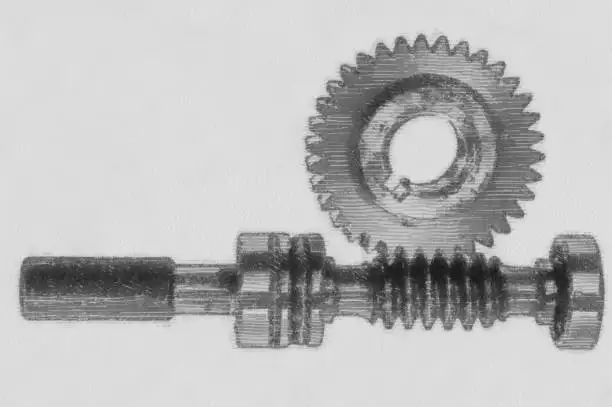

Small Worm Gears

Small worm gears are essential mechanical components designed for efficient power transmission and torque multiplication. Made from high-strength materials like aluminum or steel, these gears offer durability and reliability in various applications. Their compact size makes small worm gears ideal for tight spaces, while the mini worm gear variants are perfect for miniature devices. Additionally, miniature worm gear sets provide versatility in design, enabling precise movement in robotics and automation projects. Overall, small worm gears are crucial for enhancing performance in various engineering solutions.

Specifications of Small Worm Gears

| Parameter | Value |

|---|---|

| Material | Aluminum Alloy |

| Gear Ratio | 10:1 |

| Pitch Diameter | 25 mm |

| Outer Diameter | 35 mm |

| Width | 10 mm |

| Maximum Load | 500 N |

| Operating Temperature | -20 to 100 °C |

Features and Advantages of Small Worm Gears

- Compact Size: Small worm gears are designed to be mini worm gear solutions, ideal for tight spaces.

- High Torque: They provide a remarkable torque output, making them perfect for applications requiring high power in miniature formats.

- Smooth Operation: The design of miniature worm gears allows for quiet and smooth operation, reducing noise in machinery.

- Versatile Applications: Small worm gear sets are suitable for various applications, from robotics to small appliances.

- Durable Construction: Made from high-quality materials, these miniature worm gears offer longevity and reliability.

Understanding the Mechanism of Small Worm Gears

Small worm gears are essential components in various mechanical systems, providing efficient torque transfer and motion control. The unique design of the miniature worm gears allows for high reduction ratios in a compact form factor. These small worm gears are commonly used in applications requiring precision and reliability, such as robotics and miniature machinery. The availability of miniature worm gear sets enhances versatility, allowing for customized solutions.

Maintenance Tips for Small Worm Gears

- Regular Lubrication: To ensure the optimal performance of small worm gears, it is essential to regularly apply suitable lubricants. Lubrication reduces friction between the gear surfaces, preventing overheating and wear. For miniature worm gears, choose a lubricant that can withstand high temperatures and pressures. Pay attention to the manufacturer's recommendations for the frequency and type of lubricant. Regularly check for signs of insufficient lubrication, such as increased noise or heat, and apply lubricant as needed to extend the life of your miniature worm gear sets.

- Routine Inspection for Wear: Conducting routine inspections on small worm gears is crucial for identifying early signs of wear. Look for any signs of pitting, scoring, or abnormal wear patterns on the gear teeth. Use a magnifying tool to enhance visibility during the inspection. If you notice any significant wear on your mini worm gear, consider replacing it to avoid further damage. Regularly checking the alignment and mesh of your miniature worm gears can also help maintain their performance and longevity.

- Proper Installation and Alignment: Correct installation and alignment of small worm gears are vital for their efficient operation. Ensure that the gears are mounted securely and that the axes are aligned properly. Misalignment can lead to uneven wear and increased friction, adversely affecting the performance of the miniature worm gear sets. Use alignment tools to verify the correct positioning, and make adjustments as necessary. Proper installation not only improves efficiency but also extends the overall lifespan of your small worm gears.

Worm Gear Manufacturer - GBC

Worm gears play a crucial role in mechanical systems, offering high torque and reducing speed efficiently. Choosing a reliable supplier is essential to ensure quality and performance in any application. GBC is proud to be the Australian sales agent for Ever-power Group, positioning ourselves as one of the leading suppliers and manufacturers of worm gears in Australia.

We specialize in small worm gears, which are critical in various applications, providing precision and durability. Our products are designed to meet the highest standards, ensuring they can handle the demands of your projects effectively.

At GBC, we pride ourselves on our strength and service. Our experienced team is dedicated to providing top-notch support and guidance to help you find the perfect solution for your needs.

Additional information

| Edited | Sylvia |

|---|

Small worm gears are essential mechanical components designed for efficient power transmission and torque multiplication. Made from high-strength materials like aluminum or steel, these gears offer durability and reliability in various applications. Their compact size makes small worm gears ideal for tight spaces, while the mini worm gear variants are perfect for miniature devices. Additionally, miniature worm gear sets provide versatility in design, enabling precise movement in robotics and automation projects. Overall, small worm gears are crucial for enhancing performance in various engineering solutions.