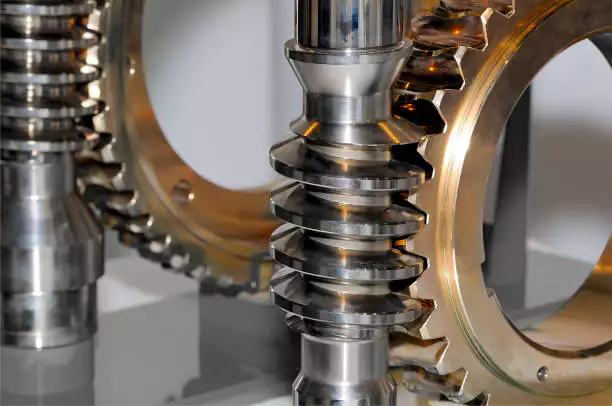

Worm Gear Shaft

The Worm Gear Shaft is a crucial component in mechanical systems, designed to transfer power and motion between non-parallel shafts. Made from high-strength steel or aluminum, this durable shaft ensures efficient performance and longevity. The unique design of the Worm Gear Drive Shaft allows for smooth operation with minimal backlash, making it ideal for applications requiring precise movement. Its versatility and robust construction make the Worm Gear Shaft an essential choice for various industrial and automotive uses.

Specifications of Worm Gear Shaft

| Model Number | M1,M2,M3,M4,M5,M8,M12 and etc. |

| Material | Brass, C45 steel, Stainless steel, Copper, POM, Aluminum, Alloy, and so on |

| Surface treatment | Zinc-plated, Nickel plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating, and Electrophoresis |

| Standard | ISO, DIN, ANSI, JIS, BS, and Non-standard. |

| Precision | DIN6,DIN7,DIN8,DIN9. |

| Teeth treatment | Hardened, Milled, or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sandblast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, L/C |

| Production lead time | 20 business days for the sample,25 days for the bulk |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Features and Advantages of Worm Gear Shaft

- High Torque Transmission: The Worm Gear Shaft is designed to efficiently transfer high torque, making it ideal for heavy-duty applications.

- Space-Saving Design: Its compact size allows for installations in tight spaces without sacrificing performance.

- Low Backlash: With minimal backlash, the Worm Gear Drive Shaft provides precise positioning and smooth operation.

- Durability: Made from high-quality materials, it ensures longevity and reliability under various conditions.

- Versatility: Suitable for a wide range of industries, including automotive, manufacturing, and robotics.

Understanding the Functionality of Worm Gear Shaft

The Worm Gear Shaft is a crucial component in mechanical systems, providing high torque and precise movement. It operates on the principle of a worm screw and a worm wheel, allowing for smooth transmission of power. The unique design enables the Worm Gear Drive Shaft to convert rotational motion while reducing speed, making it ideal for various applications, including conveyor systems and automotive mechanisms. This efficiency is enhanced by the durability and reliability of the materials used in its construction.

Maintenance Tips for Worm Gear Shaft

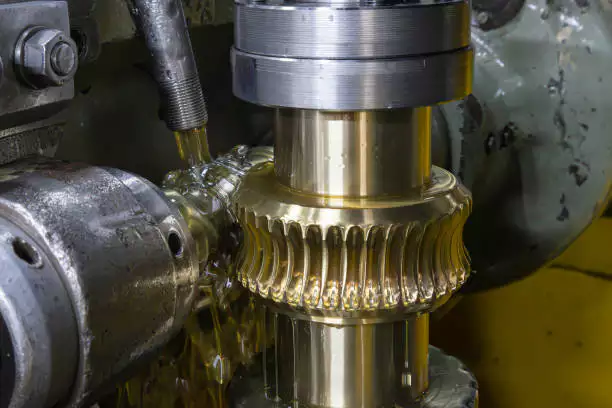

- Regular Lubrication: To ensure the smooth operation of the Worm Gear Drive Shaft, it is essential to maintain proper lubrication. This helps reduce friction and wear on the shaft, enhancing its efficiency. Use high-quality lubricants suitable for worm gear applications. Regularly check the lubricant level and replace it as needed to prevent overheating and potential damage. A well-lubricated Worm Gear Shaft will not only last longer but also perform better under load.

- Routine Inspections: Conducting routine inspections of the Worm Gear Shaft is crucial for identifying any signs of wear or damage early on. Check for unusual noises, vibrations, or leaks, which may indicate problems. Pay attention to the gear teeth for signs of pitting or chips, as these can significantly affect performance. Addressing issues promptly can prevent costly repairs and extend the lifespan of the Worm Gear Drive Shaft.

- Proper Alignment: Ensuring that the Worm Gear Shaft is correctly aligned is vital to its longevity. Misalignment can cause uneven wear and excessive stress on the gears, leading to premature failure. Use alignment tools to verify that the shaft is positioned correctly relative to the worm gear. Regular alignment checks should be part of your maintenance routine to keep the system running smoothly and efficiently.

- Temperature Control: Keeping the operating temperature of the Worm Gear Drive Shaft within recommended limits is essential to prevent degradation of materials and premature wear. Excessive heat can increase the risk of failure and reduce lubrication effectiveness. Monitor the operating environment and implement cooling solutions if necessary. By managing temperature effectively, you can significantly prolong the life of your Worm Gear Shaft.

Worm Gear Manufacturer - GBC

Worm gears play a crucial role in various mechanical systems, providing efficient torque and speed reduction. Choosing the right supplier is essential for ensuring product quality and reliability. GBC is proud to be the sales agent for Ever-power Group in Australia, establishing ourselves as one of the leading suppliers and manufacturers of worm gears in the region.

Our product offerings include high-quality Worm Gear Shafts designed for optimal performance in diverse applications. These shafts are engineered to deliver superior strength and durability, ensuring longevity and efficiency in your machinery.

At GBC, we pride ourselves on our strong capabilities and exceptional service. Our experienced team is dedicated to providing custom solutions tailored to your specific needs, ensuring you receive the best support throughout your purchasing journey.

Additional information

| Edited | Sylvia |

|---|

The Worm Gear Shaft is a crucial component in mechanical systems, designed to transfer power and motion between non-parallel shafts. Made from high-strength steel or aluminum, this durable shaft ensures efficient performance and longevity. The unique design of the Worm Gear Drive Shaft allows for smooth operation with minimal backlash, making it ideal for applications requiring precise movement. Its versatility and robust construction make the Worm Gear Shaft an essential choice for various industrial and automotive uses.