1. Introduction

A coupling is a mechanical device that is widely used in various transmission systems for connecting and transmitting power. The principle is to connect two shafts by means of a coupling so that they can rotate at the same angular speed and can move to some extent in axial and radial directions. The design and selection of couplings have an important influence on the stability and efficiency of the transmission system. In this paper, we will introduce the application of the coupling principle in life.

2 Application areas

2.1 Electric tools

– Electric tools such as drills, hammers, etc. often need to rotate at high speeds, and the direction of rotation needs to be flexible. At this time, the coupling can play the role of connecting the motor and the tool head to realize the transmission of force and direction of rotation. – The coupling of power tools usually choose flexible coupling, which can effectively reduce vibration and noise.

2.2 Automobile industry

– In the transmission system of automobile, couplings are widely used in the connection between engine and transmission, as well as the connection between different shafts. – The selection of couplings should take into account the working environment of the automobile, such as torque, speed, temperature and other factors, and should be able to ensure the reliability and safety of the transmission.

2.3 Industrial machinery

– In the field of industrial machinery, couplings are widely used in a variety of transmission systems, such as conveyor belts, fans, pumps and so on. – Couplings play a role in connecting and transmitting power in mechanical transmission, which can reduce the wear and tear of mechanical parts and improve transmission efficiency.

3. Coupling principle

3.1 Basic principle

– The basic principle of the coupling is to transfer torque by connecting the two ends of the shaft and utilizing the contact surface between the shaft and the coupling. – The coupling allows the shafts to move relative to each other to a certain extent, enabling the shafts to be deflected at certain angles and distances, thus adapting to different operating conditions.

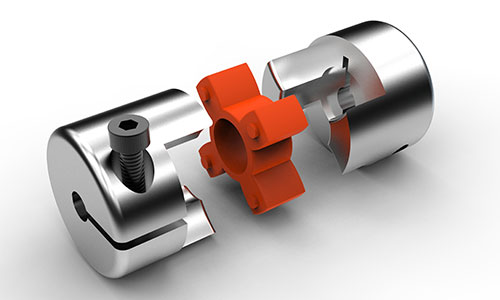

3.2 Types of couplings

– There are various types of couplings, the common ones being flexible couplings, gear couplings, universal couplings, etc. Different types of couplings are suitable for different applications. – Different types of couplings are suitable for different working conditions and transmission requirements, the choice of suitable couplings can improve the efficiency and reliability of the transmission system.

4. Coupling selection and maintenance

4.1 Coupling selection

– Coupling selection should take into account the working environment of the transmission system and transmission requirements. – Factors to be considered include torque, rotational speed, axial and radial deflections, etc. – In addition, factors such as coupling material, construction and durability need to be considered.

4.2 Maintenance of the coupling

– Couplings need to be inspected and maintained regularly during use to ensure that they work properly. – Regularly check whether the bearings are abnormally worn and whether there are problems such as looseness between the shaft and the coupling. – It is necessary to replace the coupling with serious wear in time according to the use of the coupling.

5. Conclusion

As a common mechanical transmission device, the coupling is widely used in life. It plays an important role in power tools, automotive industry, industrial machinery and other fields. Understanding the principle and selection method of coupling can help people better apply and maintain the coupling and improve the efficiency and reliability of the transmission system.