Plate Wheel Sprocket 08B-1-2-3

The Plate Wheel Sprocket 08B-1-2-3 is designed for robust performance and durability in various mechanical applications. With precise engineering and high-quality materials, this sprocket ensures reliable power transmission and minimal wear over time. GBC proudly offers top-quality Plate Wheel Sprockets in Australia, meeting the highest industry standards.

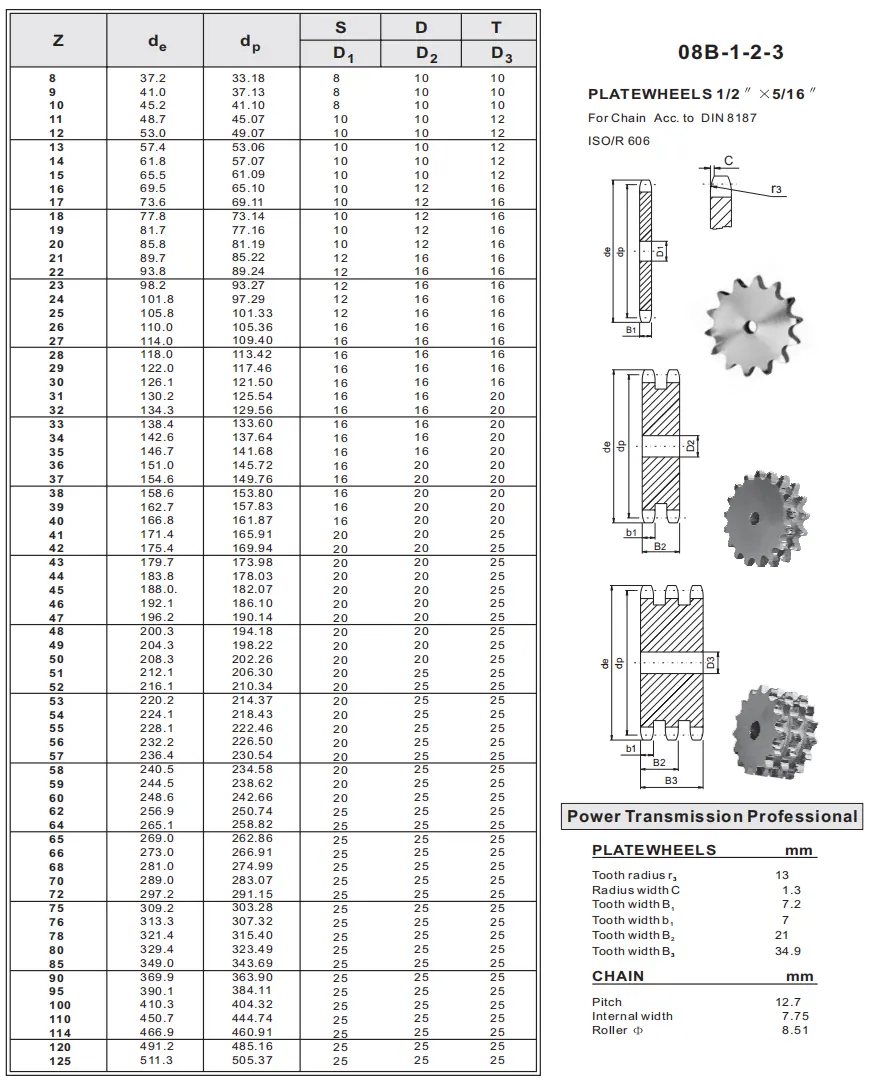

Specifications of Plate Wheel Sprocket 08B-1-2-3

Plate Wheel Sprocket 08B-1-2-3 is a specialized component designed for use in transmission systems, particularly within chain drive mechanisms. This sprocket facilitates the efficient transfer of power between rotating shafts, acting as a crucial link in the motion transmission process. The plate wheel is characterized by its robust structure, featuring a series of precisely engineered teeth that interlock with chain links, thereby enabling the reliable conveyance of motion and torque across various machinery applications.

Types of Plate Wheels

Plate wheels can be effectively categorized into three distinct types: single-row, double-row, and multi-row. Single-row plate wheels, as the name suggests, have a single set of teeth designed for straightforward applications. In contrast, double-row and multi-row plate wheels incorporate multiple sets of teeth, allowing for increased load-bearing capacity and efficiency. The selection of the appropriate type of plate wheel is contingent upon the specific operational requirements of the transmission system, including load, speed, and environmental conditions, ensuring optimal performance.

Product Features of Platewheel Sprockets

Our Plate Wheel Sprockets boast a range of impressive features tailored for diverse applications. They are constructed from high-quality materials that provide exceptional resistance to corrosion and wear, ensuring longevity and durability. Furthermore, these sprockets are designed with a lightweight structure that does not compromise on strength, allowing for efficient energy transfer and reliable operation. To enhance their lifespan, our plate wheel sprockets undergo specialized surface treatment processes that significantly improve their resistance to rust, making them suitable for both indoor and outdoor conditions.

Our Services

GBC - Ever-power Australia Agency provides a comprehensive array of services tailored to meet the unique needs of our clientele. Our offerings include custom design services based on detailed drawings provided by clients, ensuring that every sprocket meets specific operational requirements. We assist in material selection, taking into account the unique demands of each application, and offer various surface treatment options to enhance the performance and durability of the sprockets. Additionally, our hardening processes help to fortify the sprockets, while customized packaging solutions ensure that they reach customers in pristine condition.

Chain Wheel Manufacturing Process

- Forging: The initial shaping of the plate wheel through the application of significant force to create the basic form.

- Machining: Precise machining processes are employed to refine the dimensions of the forged plate wheel, ensuring accuracy.

- Hobbing: This stage involves the cutting of teeth into the plate wheel, allowing for the creation of the desired tooth profile essential for engagement with the chain.

- Teeth Heating: Heat treatment is applied to the teeth to enhance their hardness and overall durability, making them more resilient during operation.

- Treated on Quenching: A quenching process is utilized to further improve the hardness of the plate wheel, increasing its performance capabilities.

- Surface Treatment/Rust-Proof Treatment: Surface treatments are applied to safeguard the plate wheel against corrosion and rust, significantly extending its lifespan.

- Quality Inspection: Each plate wheel undergoes a thorough quality inspection to ensure it meets stringent industry standards and specifications.

- Packing: Proper packaging methods are employed to secure the plate wheels for safe and damage-free transportation.

- Shipping: The final step involves the delivery of the plate wheels to the customer¡¯s designated location, ensuring timely and efficient service.

Maintenance of Plate Wheels

- Daily Inspection: Conduct regular inspections of the plate wheels to identify any signs of damage, misalignment, or excessive wear that could affect performance.

- Cleaning: It is essential to keep the plate wheels clean and free from dirt, debris, and lubricant buildup to maintain optimal functionality.

- Lubrication: Appropriate lubrication must be applied to ensure smooth operation and minimize friction between the chain and plate wheels, enhancing their longevity.

- Replacement: Timely replacement of worn or damaged plate wheels is crucial to prevent further damage to the transmission system and to maintain its overall performance.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent of Ever-power Group, and we are one of the top ten gear suppliers in Australia. Our extensive range of gear products includes the Plate Wheel Sprocket 08B-1-2-3, which showcases our commitment to quality and diversity in gear manufacturing. As a supplier, we pride ourselves on offering a wide variety of gears that cater to different industrial needs.

We provide not only standard plate wheel sprockets but also specialize in custom non-standard solutions tailored to our clients' specific requirements. Our team is dedicated to ensuring that we meet the unique demands of our customers with precision and quality. We invite all customers to bring their designs and samples for custom orders.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket 08B-1-2-3 is designed for robust performance and durability in various mechanical applications. With precise engineering and high-quality materials, this sprocket ensures reliable power transmission and minimal wear over time. GBC proudly offers top-quality Plate Wheel Sprockets in Australia, meeting the highest industry standards.