Plate Wheel Sprocket 16B-1-2-3

The Plate Wheel Sprocket 16B-1-2-3 is designed for optimal performance and durability in various industrial applications. Its robust construction ensures longevity, while its precise engineering allows for smooth operation. Ideal for heavy-duty use, this sprocket enhances efficiency and reliability in machinery. GBC proudly offers high-quality Plate Wheel Sprockets in Australia.

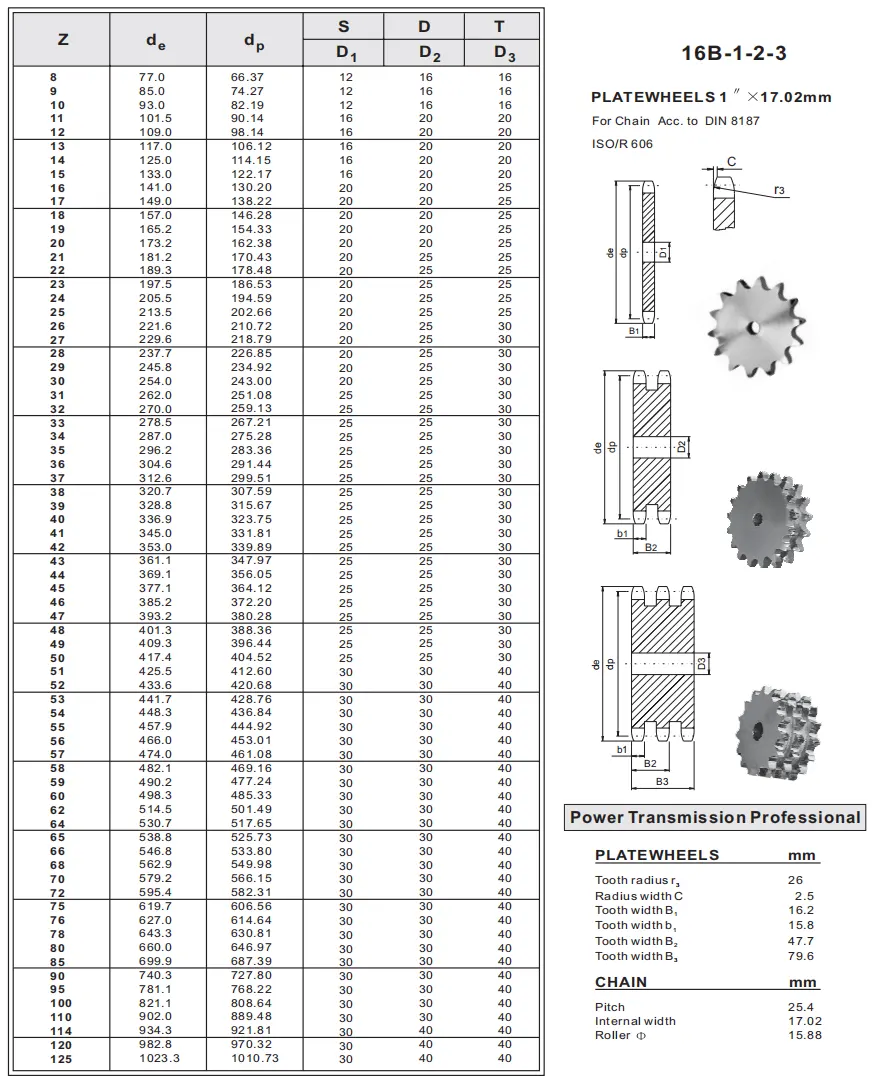

Specifications of Plate Wheel Sprocket 16B-1-2-3

The Plate Wheel Sprocket 16B-1-2-3 represents a vital component within various transmission systems. This specific type of sprocket is engineered to effectively transfer motion and power, acting as a bridge between different segments of the mechanical system. Its structure primarily consists of a circular disc featuring meticulously arranged teeth along its outer edge. These teeth interact seamlessly with chain links, facilitating an efficient transmission of power, which is crucial for the smooth operation of machinery.

Types of Plate Wheel Sprockets

Plate wheel sprockets are available in various configurations, such as single-row, double-row, and multi-row designs. The selection of the appropriate type is contingent upon the specific demands of the transmission system and the load it is intended to support. Single-row sprockets are typically favored for straightforward applications due to their simplicity, while double-row and multi-row sprockets are better suited for more intricate systems that require higher power outputs. The diversity in design ensures that users can choose a sprocket that best meets their operational needs.

Product Features of our Plate Wheel Sprockets

Our plate wheel sprockets provide numerous advantages, particularly concerning the quality of materials used and their innovative design features:

- Material Advantages: Our sprockets are constructed from materials that resist corrosion and wear, ensuring they have a long service life. These materials are selected for their strength and toughness, enabling the sprockets to endure even the most demanding operating conditions without compromising performance.

- Design Features: The design of the sprockets prioritizes lightweight construction, which contributes to the overall efficiency of the system in which they are utilized. Each sprocket undergoes precision manufacturing processes that guarantee exact dimensions and optimal operational smoothness. To protect against wear, they are enhanced with surface treatments that provide additional defense against rust.

Services We Provide

We are committed to offering a comprehensive range of services tailored to our customers' distinct needs:

- Customization: We specialize in providing customization options based on detailed customer drawings or specifications, ensuring that the sprockets fit precisely within their intended applications.

- Material Selection: Customers benefit from a variety of material choices, allowing them to select the most appropriate and effective material for their unique applications.

- Surface Treatment: We implement surface treatments designed to enhance the performance of the sprockets while also providing protection against corrosion, thus extending their lifespan.

- Hardening Treatment: Should the need arise, we offer heat treatment processes to augment the hardness and overall durability of our sprockets.

- Customized Packaging: Understanding the importance of safe delivery, we provide tailored packaging solutions that ensure our products arrive intact.

Chain Wheel Manufacturing Process

The manufacturing process for our chain wheels encompasses several critical stages that ensure high-quality output:

- Forging: The first step involves shaping the sprockets using advanced forging techniques that provide the foundational structure.

- Machining: Each sprocket is then subjected to precise machining processes, which refine the dimensions and achieve smooth surface finishes essential for optimal performance.

- Hobbing: This stage includes cutting the teeth into the sprockets using specialized hobbing machines, which is fundamental for the sprocket's functionality.

- Teeth Heating: To enhance strength and durability, the teeth of the sprocket undergo heat treatment, increasing their hardness.

- Treated on Quenching: Following heating, the sprockets are quenched to further improve their hardness and structural integrity.

- Surface Treatment/Rust-Proof Treatment: Surface treatments are applied to protect against rust and corrosion, ensuring longevity in various environments.

- Quality Inspection: Each finished sprocket is meticulously inspected to verify that it meets all specified quality standards.

- Packing: After inspection, the sprockets are securely packed to avoid damage during transportation.

- Shipping: Finally, the packed sprockets are dispatched to our customers, ready for their operational needs.

Maintenance of Chain Wheels

To achieve optimal performance and extend the life of chain wheels, consistent and proper maintenance is essential. It is advisable to adhere to the following maintenance practices:

- Daily Inspection: Regular inspections should be conducted to identify any potential signs of damage, excessive wear, or misalignment, which can affect performance.

- Cleaning: Keeping the chain wheels clear of dirt, debris, and other contaminants is crucial, as these can significantly hinder performance and lead to premature failure.

- Lubrication: Applying the correct type and amount of lubrication is vital to ensure smooth operation and minimize friction between the chain and sprocket, which can lead to wear.

- Replacement: Any chain wheels that show signs of wear or damage should be replaced promptly to prevent further mechanical issues and maintain overall system efficiency.

Plate Wheel Sprockets Supplier in Australia

GBC is the Australian sales agent of Ever-power Group, and we are one of the top ten gear suppliers in Australia. Our extensive range of gear products includes the Plate Wheel Sprocket 16B-1-2-3, which exemplifies our commitment to quality and variety. We offer a diverse selection of sprockets designed to meet various industrial needs, ensuring that our clients can find the right solution for their applications.

As a dedicated supplier, we pride ourselves on the exceptional service we provide, assisting our customers at every stage of their order. Furthermore, we understand that not all projects require standard products; therefore, we offer non-standard customization options tailored to specific customer requirements. We invite customers to bring their designs and samples for custom plate wheel sprockets, ensuring you get exactly what you need for your operations.

Additional information

| Edited by | Sylvia |

|---|

The Plate Wheel Sprocket 16B-1-2-3 is designed for optimal performance and durability in various industrial applications. Its robust construction ensures longevity, while its precise engineering allows for smooth operation. Ideal for heavy-duty use, this sprocket enhances efficiency and reliability in machinery. GBC proudly offers high-quality Plate Wheel Sprockets in Australia.