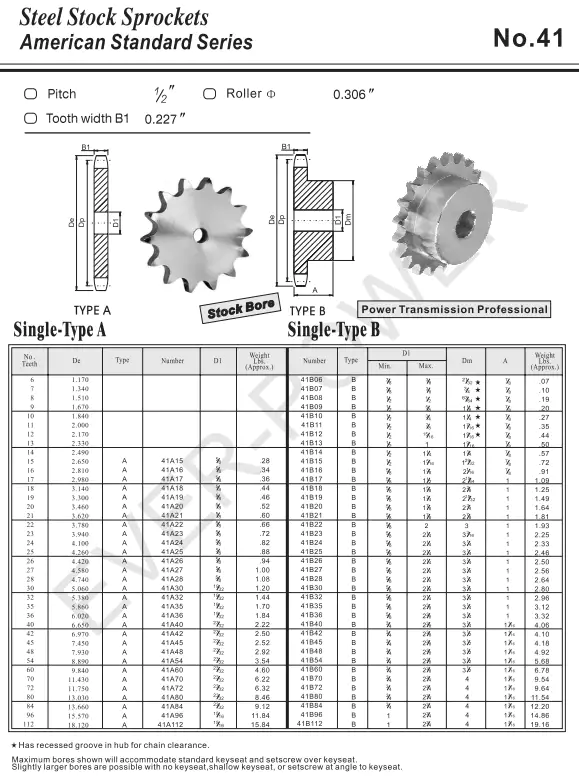

Machinable Bore Sprocket for ANSI 41 Roller Chain (1/2″ Pitch)

The Machinable Bore Sprocket for ANSI 41 Roller Chain is designed for precision and efficiency in various mechanical applications. With a 1/2″ pitch, this sprocket ensures optimal performance and durability. GBC proudly offers high-quality versions of this product in Australia, catering to all your industrial needs.

Specifications for Machinable Bore Sprocket for ANSI 41 Roller Chain (1/2" Pitch)

A machinable bore sprocket is specifically designed to facilitate the transmission of rotary motion between two shafts, with one being powered while the other remains passive. The Machinable Bore Sprocket for ANSI 41 Roller Chain is an essential component in various power transmission applications. Its versatility in tooth count and bore sizes makes it a popular choice among engineers and operators looking for reliable machinery performance.

Basic Structure of a Sprocket

A sprocket primarily consists of a circular wheel featuring teeth designed to interlock with a chain or similar material. This interaction allows for effective power transfer. When opting for a custom sprocket, several aspects require careful consideration. These include the material used, tooth profile, the total number of teeth, overall size, bore dimensions, keyway specifications, surface treatment options, and additional factors that could impact performance and durability.

41 Roller Chain 1/2 Inch Bore Sprocket Materials

The Machinable Bore Sprocket is typically constructed from high-carbon steel, alloy steel, or stainless steel, each providing unique benefits. High-carbon steel is renowned for its exceptional strength and resistance to wear, making it ideal for high-demand environments. Alloy steel, a composite of iron and other elements like chromium and nickel, enhances strength and durability further. Stainless steel offers excellent corrosion resistance, particularly in applications dealing with moisture or harsh chemicals, ensuring longevity and consistent performance.

Manufacturing Processes of 41 Roller Chain 1/2 Inch Bore Sprocket

The production of a machinable bore sprocket involves several stages, all crucial to its quality and performance. The process generally begins with material selection, followed by cutting, punching, and forging to shape the sprocket. Additional steps like machining, drilling, heat treatment, surface hardening, and rust prevention further enhance the sprocket's reliability. Quality inspection is the final step, ensuring that the finished product meets the required specifications for optimal performance and durability throughout its operational lifespan.

41 Roller Chain 1/2 Inch Bore Sprocket Applications

Machinable Bore Sprockets find extensive use across various types of heavy machinery and industrial equipment. They are integral to sectors such as food processing, chemical manufacturing, pharmaceutical operations, assembly lines, logistics, and warehousing. Their ability to withstand high torque and stress makes them a preferred choice for demanding applications, where reliability and performance are non-negotiable.

Maintenance and Care of 41 Roller Chain 1/2 Inch Bore Sprocket

To maintain optimal performance of your Machinable Bore Sprocket, regular maintenance is crucial. Key activities include daily inspections, cleaning, lubrication, and necessary adjustments. Operators should be vigilant for common issues like tooth skipping, breakage, excessive wear, noise, and chain slippage. Prompt corrective action is vital to prevent serious malfunction and ensure safe operation, thereby extending the lifespan of the sprocket and the associated equipment.

Common Problems and Solutions

- Skipping teeth: Inspect for worn teeth or chain wear and replace components as needed.

- Breakage: Examine sprocket teeth and chain for damage and replace any defective parts promptly.

- Excessive wear: Check for signs of wear and replace damaged components to maintain performance.

- Excessive noise: Investigate noises for indications of wear, replacing parts as necessary to ensure smooth operation.

- Chain slippage: Look for loose bolts or worn teeth, tightening or replacing components as required.

We also provide a variety of other sprocket types, including Platewheel Sprockets, Idler Sprockets, QD Sprockets, Taper Lock Sprockets, and more. Our sprockets are engineered to work seamlessly with our chains, offering a dependable power transmission solution tailored to your needs.

Machinable Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the best sprocket suppliers in Australia. Our commitment to quality is evident in our range of machinable bore sprockets for ANSI 41 roller chain, designed for optimal performance and durability. Each sprocket is manufactured with precision, ensuring that it meets the highest standards in the industry.

At GBC, we prioritize customer satisfaction with our exceptional pre-sales and post-sales services. Our knowledgeable team is always ready to assist you in selecting the right sprocket for your needs and providing support even after the purchase. Additionally, we offer non-standard customization options, allowing us to tailor products to meet specific customer requirements.

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 41 Roller Chain is designed for precision and efficiency in various mechanical applications. With a 1/2″ pitch, this sprocket ensures optimal performance and durability. GBC proudly offers high-quality versions of this product in Australia, catering to all your industrial needs.