Machinable Bore Sprocket for ANSI 100 Roller Chain (1 1/4″ Pitch)

The Machinable Bore Sprocket for ANSI 100 Roller Chain (1 1/4″ Pitch) is designed for precision and durability, making it ideal for various industrial applications. Its customizable bore allows for easy integration into existing systems, ensuring optimal performance. GBC is committed to providing high-quality sprockets in Australia.

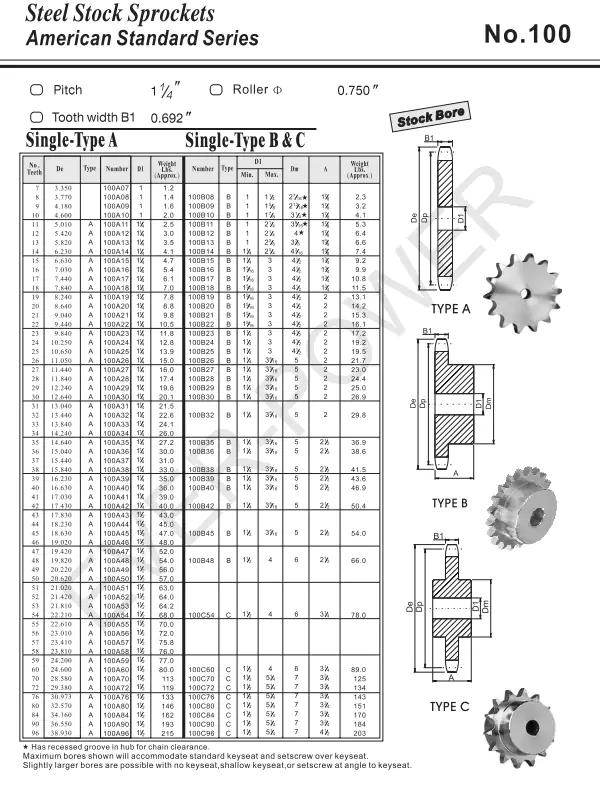

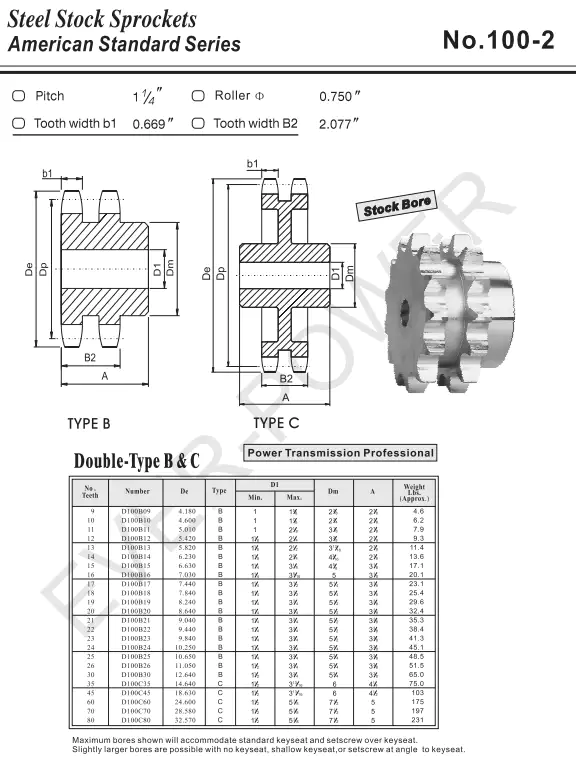

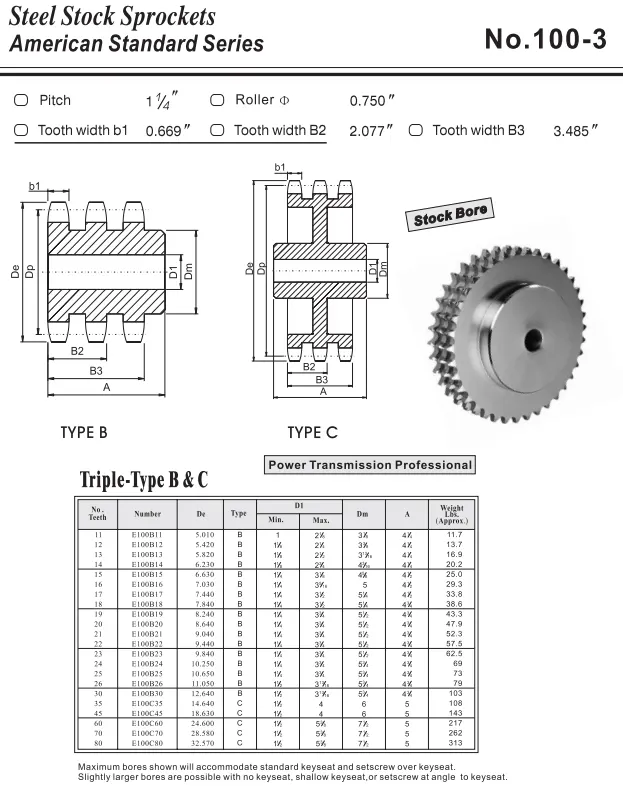

Specifications for Machinable Bore Sprocket for ANSI 100 Roller Chain (1 1/4" Pitch)

A machinable bore sprocket serves as a crucial element in numerous mechanical systems and machinery. Designed to effectively transmit rotational motion between chains and shafts, the Machinable Bore Sprocket for ANSI 100 Roller Chain (1 1/4" Pitch) is a versatile component that finds extensive application across various industries.

Basic Structure and Customization

The structure of a machinable bore sprocket comprises essential components such as teeth, a bore, and a hub. When customizing these sprockets, key factors to consider include material selection, tooth profile, the number of teeth, dimensions, bore size, keyway specifications, and surface treatments. Each of these factors plays a significant role in determining the sprocket's functionality and suitability for specific applications.

- Material

- Our machinable bore sprockets can be fabricated from high carbon steel, alloy steel, or stainless steel. Each material offers unique benefits, such as enhanced strength, corrosion resistance, and longevity. The choice of material is primarily dictated by the specific operational needs and environmental conditions of the application, ensuring that the sprocket can withstand the demands placed upon it.

- Tooth Profile

- The tooth profile of a sprocket is pivotal for ensuring seamless chain interaction and effective power transmission. Various tooth profiles are available, including standard, double pitch, and specialty versions specifically designed to address particular operational requirements. The correct tooth profile contributes to the overall efficiency and effectiveness of the mechanical system in which the sprocket is employed.

- Number of Teeth

- The total number of teeth on a sprocket is a vital factor that influences both the speed ratio and torque transmission capabilities. Selecting an appropriate number of teeth is essential to achieving the desired performance metrics and operational standards of the system, allowing for optimal functionality and efficiency in application.

- Dimensions

- The dimensions of a sprocket, including its diameter and width, are crucial aspects that must be tailored to fit the specific application and accommodate any spatial constraints. Ensuring accurate dimensions is necessary for proper alignment and integration within the mechanical system, which ultimately dictates the sprocket's performance and reliability.

- Bore Size

- The bore size denotes the diameter of the central hole that facilitates attachment to a shaft. Precise selection of bore size is essential to ensure a secure and stable connection, which is critical for maintaining the integrity of the system during operation. An incorrect bore size can lead to misalignment and potential failure of the component.

- Keyway

- A keyway is a slot located on the bore that accommodates a key for securing the sprocket to the shaft. Proper specification of the keyway's size and positioning is crucial to achieving correct alignment and preventing slippage during operation. This feature enhances the overall reliability and effectiveness of the sprocket within the system.

- Surface Treatment

- To improve the durability and resistance to wear and corrosion, sprockets often undergo various surface treatments. Techniques such as rust prevention coatings and heat treatment processes, including quenching and tempering, significantly enhance the overall performance and longevity of the sprocket, ensuring it can withstand demanding operational conditions.

1 1/4" Bore Sprocket Applications

Machinable bore sprockets have a wide range of applications across different industries, including:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical sectors

- Assembly lines

- Logistics and warehousing

Maintenance and Troubleshooting of 1 1/4" Bore Sprocket

To ensure the longevity and optimal performance of machinable bore sprockets, proper maintenance practices are essential. Here are some vital maintenance tips:

- Daily Inspection

- Conduct regular inspections of the sprocket to identify any signs of wear, damage, or misalignment. Promptly addressing any issues can prevent further complications and ensure the continued reliability of the sprocket within the system.

- Cleaning

- Keeping the sprocket clean from dirt, debris, and other contaminants is important for maintaining smooth chain engagement. Regular cleaning prevents premature wear and contributes to the overall efficiency of the mechanical system, ensuring that the sprocket operates as intended.

- Lubrication

- Applying the appropriate lubricant is essential for facilitating smooth rotation and minimizing friction between the sprocket and chain. Following the manufacturer's guidelines regarding lubricant type and application frequency will help maintain optimal performance and extend the lifespan of the sprocket.

- Adjustment and Calibration

- Regularly check and adjust the chain tension to guarantee proper engagement with the sprocket. Additionally, calibrating the alignment between the sprocket and chain may be necessary to maintain peak performance, ensuring that the system operates smoothly.

Common Issues and Solutions

Various common problems can arise with sprockets, such as:

- Skipping teeth

- Breakage

- Wear

- Excessive noise

- Chain slippage

Addressing these issues usually involves consistent maintenance and necessary adjustments. If problems persist, consulting a professional is advisable to ensure that the sprocket system functions efficiently and reliably.

Machinable 1 1/4" Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we pride ourselves on being one of the best sprocket suppliers in Australia. Our range of machinable bore sprockets for ANSI 100 roller chain (1 1/4" pitch) exemplifies our commitment to high-quality manufacturing and precision engineering. Each sprocket is designed to meet stringent industry standards, ensuring durability and performance in various applications.

At GBC, we understand the importance of exceptional customer service. Our pre-sales support ensures that you select the right product for your needs, while our after-sales service guarantees satisfaction and assistance long after your purchase. Additionally, we offer non-standard customization options tailored to meet specific customer requirements, ensuring you find the perfect solution for your project.

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 100 Roller Chain (1 1/4″ Pitch) is designed for precision and durability, making it ideal for various industrial applications. Its customizable bore allows for easy integration into existing systems, ensuring optimal performance. GBC is committed to providing high-quality sprockets in Australia.