Machinable Bore Sprocket for ANSI 240 Roller Chain (3″ Pitch)

The Machinable Bore Sprocket for ANSI 240 Roller Chain (3″ Pitch) is engineered for precision and durability, ensuring optimal performance in demanding applications. Its customizable bore allows for easy installation on various shafts, making it a versatile choice for your machinery needs. GBC proudly supplies high-quality sprockets in Australia, ensuring reliability and excellence.

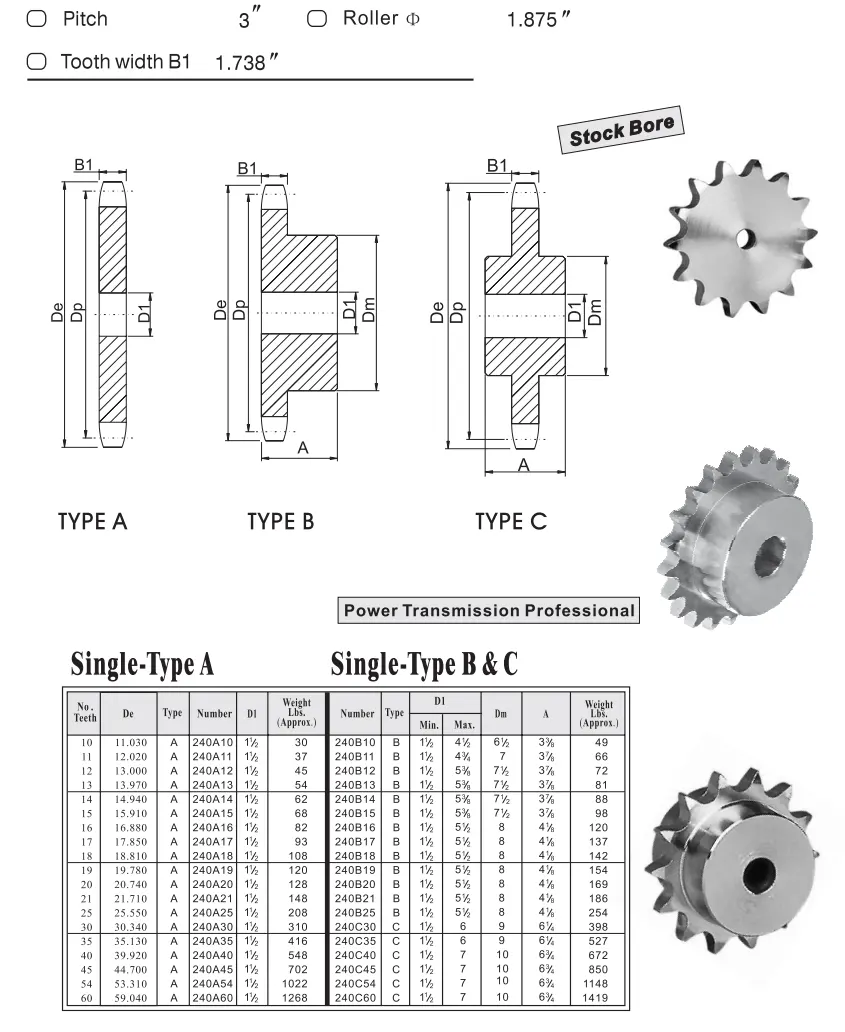

Specifications for Machinable Bore Sprocket for ANSI 240 Roller Chain (3" Pitch)

A machinable bore sprocket is a specialized type of sprocket designed to have a bore that can be precisely machined to fit various shaft sizes. The Machinable Bore Sprocket for ANSI 240 Roller Chain (3" Pitch) is tailored for a wide range of industrial applications, offering flexibility in installation and performance.

Materials and Manufacturing Process Used for Our Sprockets

The Machinable Bore Sprocket is produced using high-quality materials, such as high carbon steel, alloy steel, or stainless steel. The manufacturing process encompasses several stages:

- Material Selection: We prioritize selecting superior materials to guarantee the sprocket's quality and resilience.

- Cutting: Advanced cutting machines shape the material to the necessary dimensions, ensuring precision.

- Forging or Stamping: The teeth of the sprocket are created using forging or stamping processes, ensuring strength and durability.

- Machining: Further machining refines the sprocket to achieve stringent dimensional tolerances.

- Heat Treatment: The sprocket undergoes heat treatment to enhance hardness and resistance to wear, which is essential for prolonged use.

- Surface Treatment: Additional treatments are applied to safeguard against rust and improve performance, ensuring that the sprocket remains efficient under various conditions.

- Quality Control: A comprehensive quality control process ensures that each sprocket meets stringent industry standards, providing peace of mind to users.

Applications

The Machinable Bore Sprocket is versatile and suitable for numerous applications, including:

- Heavy Machinery and Equipment: This sprocket is ideal for heavy machinery such as cranes, excavators, and bulldozers, where reliability and strength are paramount.

- Food Processing and Packaging: Made from food-grade materials, our sprocket is perfectly suited for food processing and packaging machinery, ensuring adherence to safety standards.

- Chemical and Pharmaceutical: Its resistance to corrosion makes it an excellent choice for demanding chemical and pharmaceutical environments, where exposure to harsh substances is common.

- Assembly Lines: The sprocket plays a critical role in assembly lines, where it facilitates power transfer between various components, enhancing efficiency in production processes.

- Logistics and Warehousing: It is also utilized in logistics and warehousing applications, including conveyor belts and elevators, providing reliable operation for moving goods.

Maintenance and Common Issues

Proper maintenance is essential for ensuring the longevity and effectiveness of the sprocket. Here are essential maintenance tips:

- Daily Inspection: Regularly inspect the sprocket for signs of wear, damage, or misalignment, which can affect performance.

- Cleaning: Keep the sprocket clean by removing debris and dirt regularly, supporting smooth operation and efficiency.

- Lubrication: Periodic lubrication is vital to minimize wear and prevent rust formation, enhancing the sprocket's lifespan.

- Adjustment and Calibration: Regularly check that the sprocket is correctly aligned and calibrated to avoid operational issues.

Common issues encountered with sprockets include:

- Jumping Teeth: Sprocket teeth may jump if worn or misaligned. This can usually be remedied by adjusting or replacing the sprocket.

- Breakage: Excessive loads or wear can lead to breakage, necessitating immediate replacement to maintain operational integrity.

- Excessive Wear: Lack of lubrication or misalignment can cause abnormal wear, which can be addressed by ensuring proper lubrication and alignment.

- Noise: Excessive noise often indicates wear or misalignment, indicating a need for adjustment or replacement.

- Chain Slippage: Worn sprockets or incorrect calibration may result in chain slippage, which requires immediate attention to prevent further issues.

Machinable Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the best sprocket suppliers in Australia. Our range includes the Machinable Bore Sprocket for ANSI 240 Roller Chain (3" Pitch), which is engineered to meet high standards of quality and performance. We prioritize precision manufacturing, ensuring that each sprocket fits perfectly and operates efficiently.

At GBC, we are committed to providing excellent pre-sale and post-sale services. Our knowledgeable team is ready to assist customers with any inquiries, ensuring a smooth purchasing experience. We also stand by our products and offer dedicated support after the sale to address any concerns that may arise.

Additionally, we understand that each customer has unique needs, so we offer non-standard customization options to create sprockets that meet specific requirements. Trust GBC for your sprocket solutions!

Additional information

| Edited by | Sylvia |

|---|

The Machinable Bore Sprocket for ANSI 240 Roller Chain (3″ Pitch) is engineered for precision and durability, ensuring optimal performance in demanding applications. Its customizable bore allows for easy installation on various shafts, making it a versatile choice for your machinery needs. GBC proudly supplies high-quality sprockets in Australia, ensuring reliability and excellence.