08B-1 European Standard Finished Bore Sprocket

The 08B-1 European Standard Finished Bore Sprocket is designed for high-performance applications, ensuring durability and efficiency in power transmission systems. Engineered with precision, this sprocket features a robust construction that adheres to European standards, making it ideal for various industrial uses. Its finished bore allows for easy installation on a range of shafts, providing versatility across different machinery. GBC proudly offers the 08B-1 sprocket in Australia, ensuring top-quality products for our customers.

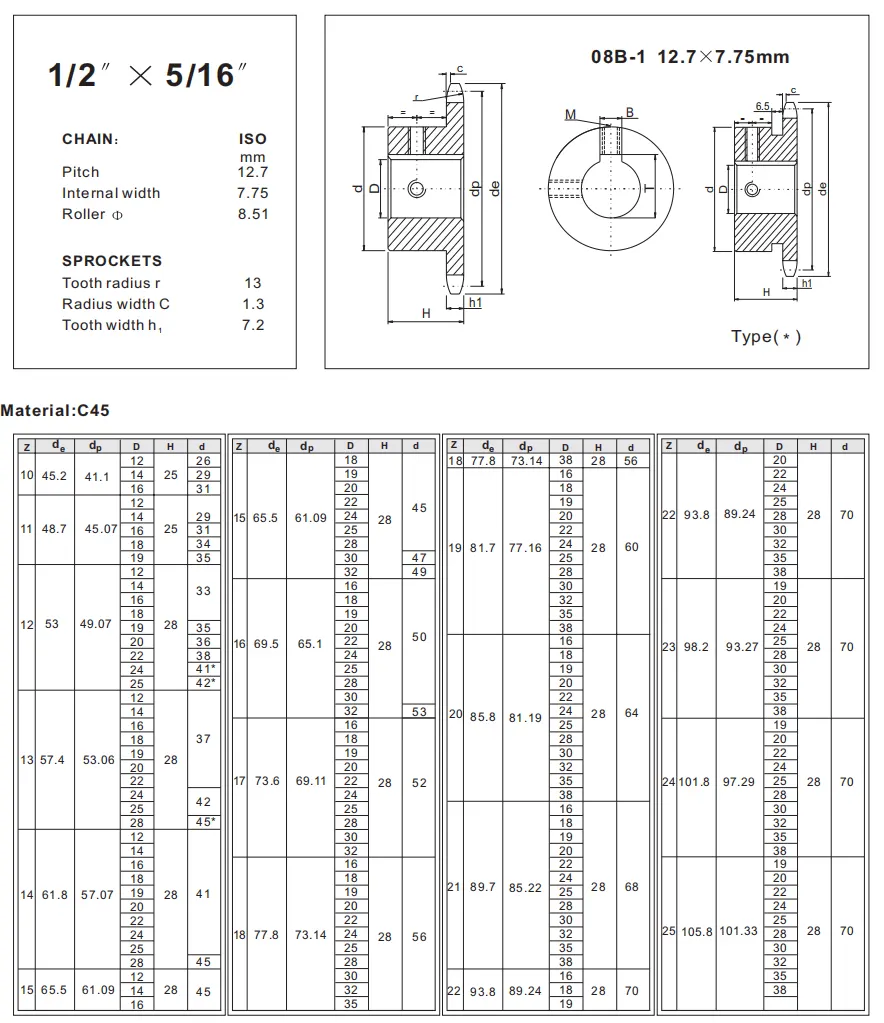

Specifications of 08B-1 European Standard Finished Bore Sprocket

A finished bore sprocket is a crucial component in power transmission, utilized alongside roller chains to effectively transfer motion and power between rotating shafts. The 08B-1 European Standard represents a widely used type of finished bore sprocket across various applications.

Materials and Manufacturing Process

Our finished bore sprockets are crafted from premium materials such as high carbon steel, alloy steel, or stainless steel. These materials are selected for their exceptional strength, durability, and resistance to wear and corrosion. The manufacturing process includes material selection, cutting, punching, forging, CNC machining, heat treating, and surface hardening. Additionally, surface treatment is applied to prevent rust and enhance longevity. All our sprockets undergo rigorous quality control testing to ensure compliance with industry standards.

Applications

Finished bore sprockets find use in a diverse array of industrial applications, including:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical manufacturing

- Assembly lines

- Logistics and warehousing

These sprockets are vital for transmitting power and motion between rotating shafts in numerous industrial machines and equipment.

Maintenance and Troubleshooting

To prevent problems and extend the lifespan of your finished bore sprocket, regular maintenance and inspection are crucial. Key maintenance tips include:

- Conducting routine inspections

- Cleaning and lubricating the sprocket

- Adjusting and calibrating the sprocket

Common issues associated with finished bore sprockets include:

- Skipping teeth

- Breaking

- Wearing

- Noise issues

- Chain slippage

Promptly addressing any of these issues is essential to prevent further damage to the sprocket and adjacent equipment. Solutions may include replacing the sprocket, adjusting the chain tension, and lubricating the sprocket.

Other Products

Besides finished bore sprockets, we offer a range of other sprocket types, such as taper lock sprockets, QD sprockets, and idler sprockets. We also provide various types and sizes of roller chains tailored to meet your specific application requirements.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, providing high-quality engineering solutions. Our product range includes the 08B-1 European Standard Finished Bore Sprocket, which is designed for durability and efficiency in various applications. These sprockets are manufactured to meet stringent quality standards, ensuring optimal performance in your machinery.

In addition to our standard sprockets, we offer custom non-standard sprocket solutions tailored to meet the specific requirements of our clients. We encourage customers to provide their designs or samples for bespoke manufacturing. Our dedicated team is ready to assist you in finding the right solution for your needs.

Additional information

| Edited by | Sylvia |

|---|

The 08B-1 European Standard Finished Bore Sprocket is designed for high-performance applications, ensuring durability and efficiency in power transmission systems. Engineered with precision, this sprocket features a robust construction that adheres to European standards, making it ideal for various industrial uses. Its finished bore allows for easy installation on a range of shafts, providing versatility across different machinery. GBC proudly offers the 08B-1 sprocket in Australia, ensuring top-quality products for our customers.