Metric Bore Sprocket for ISO 081B Roller Chain (12.7mm Pitch)

The Metric Bore Sprocket for ISO 606 and DIN 8187 081B Roller Chain is designed for precise performance and durability. With a pitch of 12.7mm, it ensures smooth operation and effective power transmission in various applications. GBC proudly offers high-quality Metric Bore Sprockets in Australia, ensuring reliability and excellence.

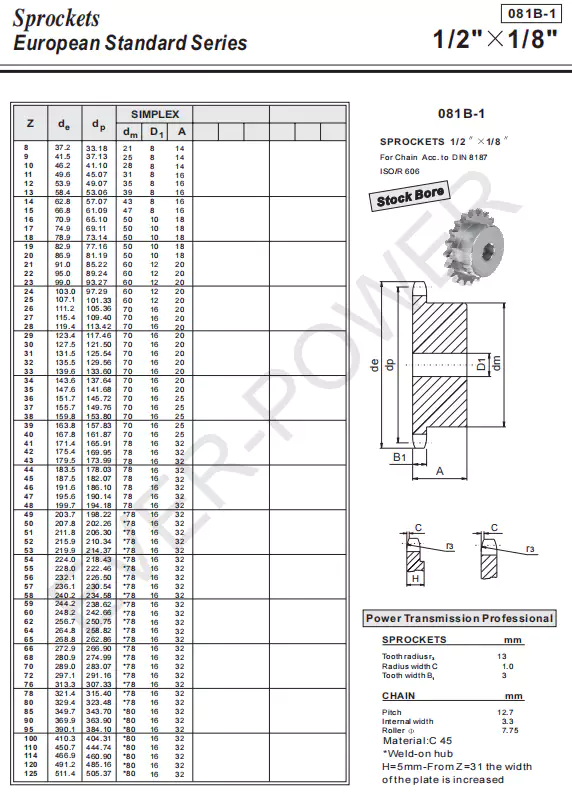

Specifications: Metric Bore Sprocket for ISO 081B Roller Chain (12.7mm Pitch)

A metric bore sprocket is specifically designed to accommodate ISO 081B roller chains with a pitch of 12.7mm. These sprockets feature a pre-bored hole that allows for easy integration onto various shaft sizes. Their versatility makes them ideal in diverse applications such as conveyor systems and power transmission setups, providing reliable performance across different industrial sectors.

Basic Structure of Sprocket and Customization

The sprocket comprises a circular wheel with protruding teeth arranged around its edge, which engage with a chain or belt. This design enables the sprocket to grip the chain securely, facilitating efficient motion transfer. Customizing a sprocket involves several key considerations:

- Material: We use high carbon steel, alloy steel, or stainless steel, each offering distinct advantages tailored to specific operational demands.

- Tooth Shape: The configuration of the teeth must be compatible with the chain type to ensure optimal engagement and functionality.

- Number of Teeth: The tooth count dictates the speed ratio between the driving and driven components, making it crucial for achieving desired performance metrics.

- Dimensions: Sprocket dimensions are tailored to match the technical requirements of the application and corresponding shaft size.

- Bore Size: Accurate bore sizing is essential for a secure fit on the shaft, minimizing wear and misalignment.

- Keyway: A keyway slot on the bore prevents the sprocket from slipping during operation.

- Surface Treatment: Custom surface treatments can enhance properties such as corrosion resistance and wear longevity, depending on the operational environment.

Material and Manufacturing Process of Our Sprockets

At GBC - Ever-power Australia Agency, we prioritize quality in both materials and manufacturing processes to produce durable sprockets. Our manufacturing stages include careful material selection, precise cutting, stamping or forging, machining, and rigorous heat treatment processes designed to enhance strength and durability.

- Material Selection: We select each material based on application needs and customer specifications to ensure performance.

- Cutting: Materials are accurately cut to shape utilizing advanced saw or laser technologies.

- Stamping or Forging: This process shapes the teeth and hub, creating robust structural integrity.

- Machining: Sprocket teeth and bore dimensions are finely tuned using precision equipment.

- Heat Treatment: Strength and wear resistance are significantly improved through controlled heat treatments, including processes like quenching and tempering.

- Surface Hardening: Techniques such as carburizing are employed to enhance surface durability further.

- Surface Treatment: We offer various coatings to boost corrosion resistance and improve operational efficiency.

- Quality Inspection: Our sprockets undergo stringent quality checks to ensure they meet both customer expectations and industry standards.

Applications of Metric Bore Sprocket

Metric bore sprockets find application across an extensive array of industries, including machinery, food processing, pharmaceuticals, logistics, and warehousing. Their reliability and adaptability make them essential components in systems requiring efficient motion transfer.

Maintenance and Troubleshooting

Regular maintenance and inspections are crucial for ensuring the longevity and efficiency of sprockets. Maintenance tasks should include daily checks for wear, cleaning, lubrication, and appropriate adjustments. Common issues with sprockets may involve tooth skipping, wear, or excessive noise. To address these, adjustments in chain tension, the replacement of faulty components, and realignment can be effective solutions.

Metric Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are one of the best sprocket suppliers in Australia. Our company specializes in providing high-quality Metric Bore Sprockets suitable for ISO 081B Roller Chain with a 12.7mm pitch. We take pride in our top-notch manufacturing processes that ensure durability and reliability in every sprocket we produce.

At GBC, we prioritize customer satisfaction with our comprehensive pre-sales and after-sales services. Our experienced team is always ready to assist you in selecting the right product to meet your specific needs. Additionally, we offer customized solutions, enabling us to create non-standard sprockets tailored to our clients' requirements.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket for ISO 606 and DIN 8187 081B Roller Chain is designed for precise performance and durability. With a pitch of 12.7mm, it ensures smooth operation and effective power transmission in various applications. GBC proudly offers high-quality Metric Bore Sprockets in Australia, ensuring reliability and excellence.