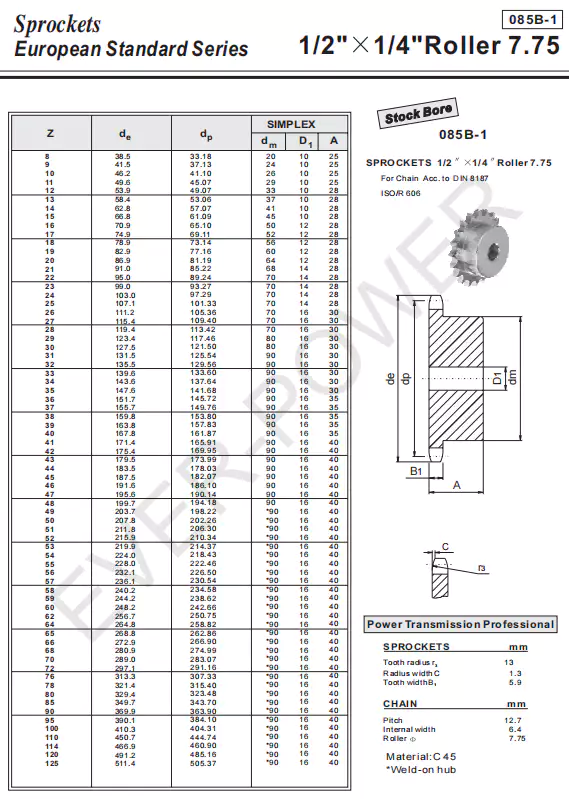

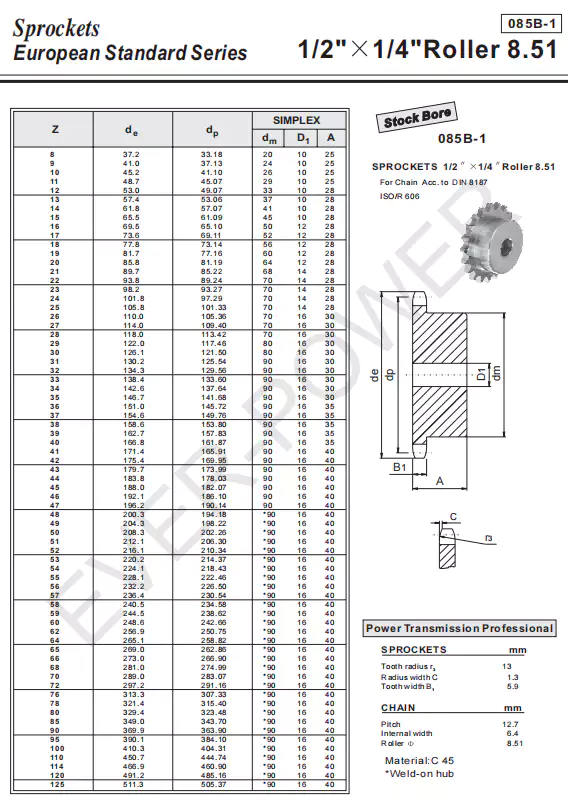

Metric Bore Sprocket for ISO 085B Roller Chain (12.7mm Pitch)

The Metric Bore Sprocket for ISO 606 and DIN 8187 085B Roller Chain features a precise 12.7mm pitch, ensuring optimal performance and durability. Designed for various applications, this sprocket provides reliable power transmission in industrial machinery. GBC proudly offers high-quality Metric Bore Sprockets in Australia, meeting rigorous industry standards.

Specifications for Metric Bore Sprocket for ISO 085B Roller Chain (12.7mm Pitch)

The Metric Bore Sprocket for ISO 085B Roller Chain (12.7mm Pitch) plays a vital role in mechanical systems by facilitating the transfer of rotary motion between shafts. This component consists of a wheel equipped with teeth designed to mesh with chain links, enabling seamless and efficient power transmission.

Structure of Sprocket

When designing a sprocket for specific applications, several critical factors must be considered to maximize performance. These factors include:

- Material: Selecting the appropriate material for the sprocket is crucial and varies based on the application. High carbon steel, alloy steel, and stainless steel are common choices, each offering different properties suited to various environments.

- Tooth Profile: The design of the tooth profile is essential as it dictates how effectively the sprocket engages with the chain. Customizing this profile according to the system’s unique requirements can enhance overall performance and longevity.

- Number of Teeth: The quantity of teeth on the sprocket directly influences the speed ratio and torque transfer capabilities. A careful selection is necessary to match the intended performance of the mechanical system and achieve optimal efficiency.

- Dimensions: Key dimensions, including the outer diameter and width of the sprocket, must be tailored to fit the specific requirements of the mechanical system in which it will be used.

- Bore Size: The size of the center bore is critical, as it ensures the sprocket fits securely onto the shaft without any play, which is essential for maintaining operational efficiency.

- Keyway: If necessary, incorporating a keyway helps ensure precise alignment and pre