Metric Bore Sprocket for ISO 08B Roller Chain (12.7mm Pitch)

The Metric Bore Sprocket for ISO 606 and DIN 8187 08B Roller Chain features a precise 12.7mm pitch, ensuring optimal performance and longevity in various applications. Designed for durability and efficiency, this sprocket is ideal for machinery requiring reliable power transmission. GBC proudly offers high-quality metric bore sprockets in Australia.

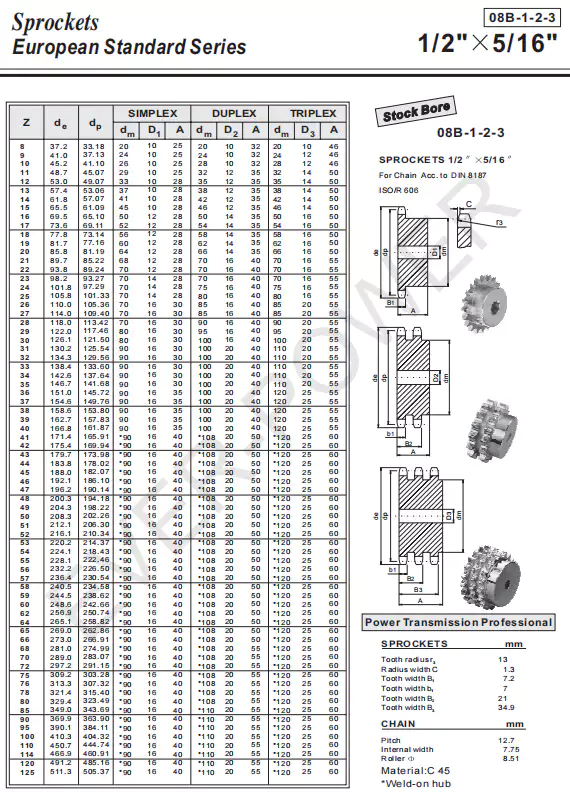

Specifications: Metric Bore Sprocket for ISO 08B Roller Chain (12.7mm Pitch)

A metric bore sprocket for ISO 08B roller chain features a precisely machined center hole that fits directly onto a shaft, eliminating the need for any further machining. The 08B-1-2-3 metric bore sprocket is specifically designed for use with 12.7mm pitch roller chains, making it a versatile component in various industrial settings. This type of sprocket ensures reliable performance and efficient power transmission, which is crucial for machinery operations across different sectors.

Basic Structure of Sprocket

Sprockets consist of multiple essential components that work together to facilitate movement and energy transfer. Key elements include the teeth, bore, keyway, and surface treatment. Each component plays a vital role in the overall functionality and durability of the sprocket.

Material

The choice of material for a metric bore sprocket depends largely on the intended application. Typically, high carbon steel, alloy steel, and stainless steel are used due to their strength and durability. High carbon steel is favored for heavy-duty applications, whereas stainless steel is preferred in environments prone to corrosion.

Tooth Profile and Count

The profile and count of the teeth on a sprocket are crucial as they must match the specifications of the chain used. A proper fit ensures smooth operation and reduces the risk of wear and tear. The design of the teeth influences how well the sprocket engages with the chain, affecting overall performance.

Size

The size of the sprocket is determined by the diameter of the chain it is intended to work with. For the ISO 08B roller chain, this means that the sprocket must be designed to accommodate a specific pitch and diameter to ensure optimal functionality and efficiency.

Bore and Keyway

The bore and keyway are critical for securing the sprocket onto the shaft. A well-designed bore allows for seamless mounting, while the keyway prevents any slippage during operation. This fitting is essential for maintaining the accuracy of the system's movements.

Surface Treatment

The surface treatment of a sprocket is essential for enhancing its longevity and performance. Treatments such as heat treatment and surface hardening provide resistance against wear and rust, ensuring that the sprocket remains functional even in challenging conditions.

Material and Process Used for Our Sprockets

Our sprockets are manufactured using high-quality materials including high carbon steel, alloy steel, and stainless steel. The manufacturing process involves careful material selection followed by cutting, punching, forging, machining, heat treatment, and surface hardening. Each step ensures that the sprocket meets rigorous quality standards, including thorough quality inspection protocols to ensure reliability.

Applications

The metric bore sprockets we offer find applications in various industries, such as heavy machinery, food processing, packaging, chemical and pharmaceutical sectors, assembly lines, logistics, and warehousing. Their versatility and robust design make them ideal for a wide range of operational demands.

Maintenance and Common Issues

Daily Inspection

Regular inspections of the sprocket are vital for early identification of potential issues. Observing signs of wear, misalignment, or unusual noises can help prevent more significant problems from developing, ensuring the system operates smoothly.

Cleaning

Keeping the sprocket clean is crucial for its longevity. Accumulation of dirt and debris can lead to operational inefficiencies and damage. Regular cleaning helps maintain optimal performance and reduces wear on both the sprocket and the chain.

Lubrication

Proper lubrication is essential for reducing friction and wear on the sprocket. Adequate lubrication minimizes the chances of overheating and extends the life of both the sprocket and the chain.

Adjustment and Calibration

Adjustments and calibrations may be necessary to ensure that the sprocket and chain are working in harmony. This may involve realigning the sprocket or making minor adjustments to the tension in the chain to achieve perfect synchronization.

Common Issues and Solutions

Common issues with sprockets can include tooth skipping, breakage, excessive wear, and chain slippage. Addressing these issues may involve adjusting alignment, replacing worn-out sprockets, or even replacing the chain to maintain optimal function.

Metric Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we are proud to be one of the leading sprocket suppliers in Australia. Our extensive range includes the Metric Bore Sprocket for ISO 08B Roller Chain (12.7mm Pitch), designed to meet the highest standards of quality and durability.

At GBC, we prioritize the satisfaction of our clients. Our products undergo rigorous quality control to ensure they perform at their best in various applications. We also offer exceptional pre-sales and post-sales services, providing customers with the support they need throughout their purchasing journey.

Furthermore, we understand that every client has unique requirements. Therefore, we offer non-standard customizations tailored to meet specific needs, ensuring that you get the perfect solution for your project.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket for ISO 606 and DIN 8187 08B Roller Chain features a precise 12.7mm pitch, ensuring optimal performance and longevity in various applications. Designed for durability and efficiency, this sprocket is ideal for machinery requiring reliable power transmission. GBC proudly offers high-quality metric bore sprockets in Australia.