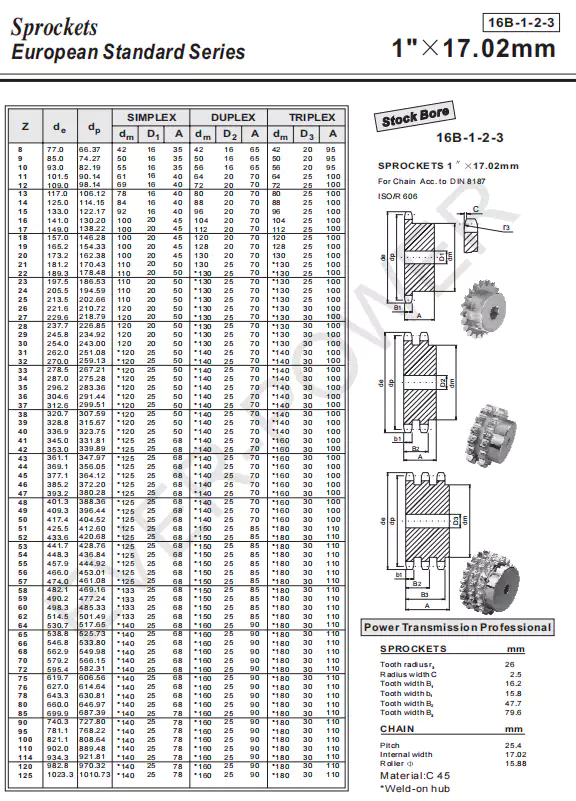

Metric Bore Sprocket for ISO 16B Roller Chain (25.4mm Pitch)

The Metric Bore Sprocket is designed specifically for ISO 606 and DIN 8187 16B roller chains with a 25.4mm pitch. Constructed from durable materials, it ensures optimal performance and longevity in various industrial applications. GBC is proud to offer high-quality Metric Bore Sprockets in Australia, meeting all your operational needs.

Specifications: Metric Bore Sprocket for ISO 16B Roller Chain (25.4mm Pitch)

Selecting a Metric Bore Sprocket for ISO Roller Chain

A standard bore sprocket is a crucial component commonly utilized in diverse industrial applications. It serves the primary purpose of transmitting rotary motion between two shafts through the use of a roller chain. This type of sprocket features a wheel with teeth that interlocks with the chain, facilitating the transfer of power and motion. As a key element in many machinery and equipment systems, its design and functionality are essential for efficient operation. To select an appropriate standard bore sprocket, several important factors should be taken into account:

Material

The material composition of standard bore sprockets can differ significantly depending on the specific requirements of each application. They may be constructed from high carbon steel, alloy steel, or stainless steel, with the right choice influenced by factors like load capacity, expected durability, and environmental conditions. Selecting the correct material is vital to ensure the sprocket can withstand operational demands and provide longevity.

Tooth Profile

The tooth profile plays a significant role in how the sprocket engages with the chain. Common profiles include the standard ANSI tooth profile and the European DIN profile. Choosing the right tooth profile is essential, as it directly impacts the performance and efficiency of the chain-sprocket interaction. Different applications may require specific profiles to optimize performance and minimize wear.

Number of Teeth

The number of teeth on a sprocket is a critical aspect that determines both the speed ratio and torque transmission capabilities. An appropriate selection of teeth based on the desired operational speed and torque requirements is essential for achieving optimal performance. An incorrect number of teeth can lead to inefficiencies and potential mechanical failure.

Dimensions

Dimensions