Metric Bore Sprocket for ISO 20B Roller Chain (31.75mm Pitch)

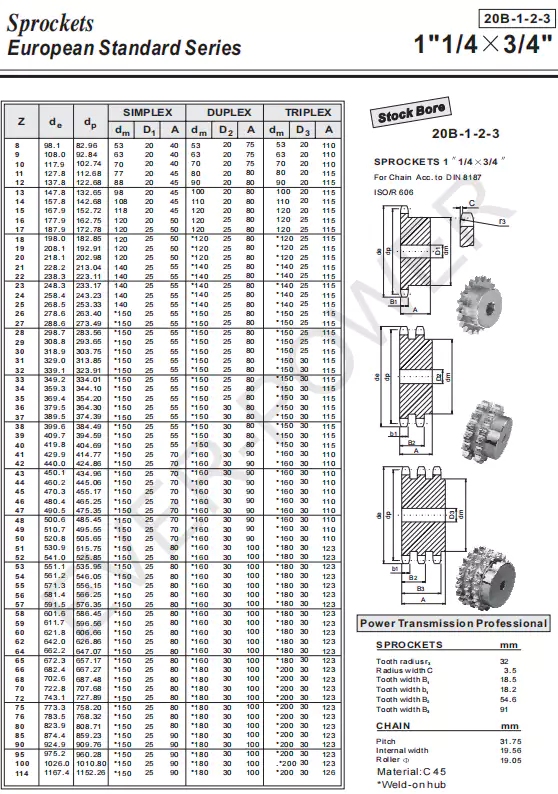

Metric Bore Sprocket for ISO 606 and DIN 8187 20B Roller Chain

The Metric Bore Sprocket is specifically designed for ISO 606 and DIN 8187 20B roller chains, featuring a 31.75mm pitch. This durable sprocket ensures efficient power transmission and optimal performance in various applications.

GBC provides high-quality Metric Bore Sprockets in Australia, ensuring reliability and performance for all your needs.

Specifications for Metric Bore Sprocket for ISO 20B Roller Chain (31.75mm Pitch)

A metric bore sprocket is specifically designed to accommodate a metric bore size with a standard keyway slot. This type of sprocket is engineered for compatibility with ISO 20B roller chains, which have a pitch of 31.75mm. The Metric Bore Sprocket for ISO 20B Roller Chain is a notable example of a metric bore sprocket, widely utilized across various industrial applications due to its reliability and efficiency.

Customization of Sprockets

Customizing a sprocket involves several critical factors:

- Material: Sprockets can be constructed from diverse materials, including high carbon steel, alloy steel, and stainless steel. The material choice is influenced by the specific application, environmental conditions, and budget constraints.

- Tooth profile: The design of the tooth profile affects how the sprocket meshes with the chain, with common profiles being standard, double pitch, and specialized shapes.

- Number of teeth: The total number of teeth plays a significant role in determining the speed ratio and torque transmission capabilities of the sprocket.

- Size: The dimensions of a sprocket are determined by the chain pitch and the number of teeth, impacting both fit and performance.

- Center bore: The center bore is the essential opening in the sprocket that fits onto the shaft. It must be precisely sized and shaped to ensure proper alignment and secure fit.

- Keyway slot: This groove within the center bore allows a key to fit, preventing the sprocket from rotating inadvertently on the shaft, which is vital for maintaining operational integrity.

- Surface treatment: Various surface treatments are applied to enhance protection against corrosion and wear.