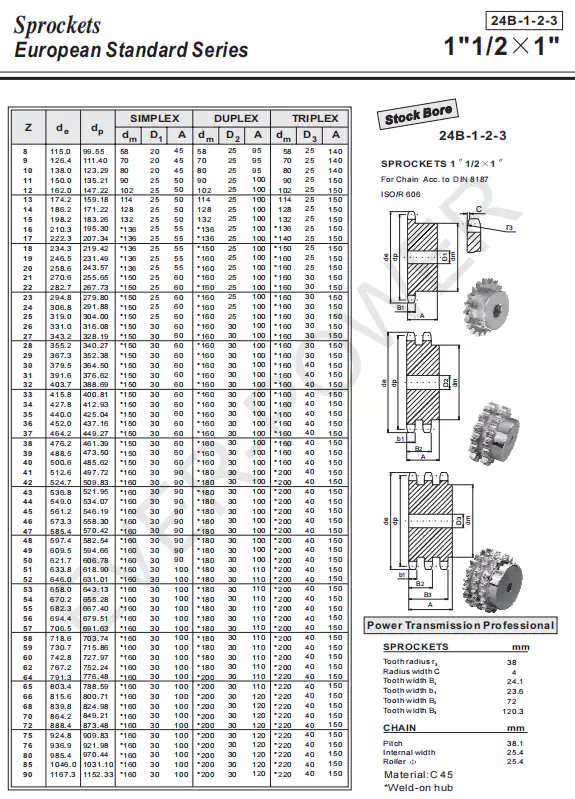

Metric Bore Sprocket for ISO 24B Roller Chain (38.1mm Pitch)

Metric Bore Sprocket for ISO 606 and DIN 8187

This Metric Bore Sprocket is specifically designed for 24B roller chains with a pitch of 38.1mm, ensuring reliable performance and durability. It is ideal for various industrial applications, providing optimal power transmission and efficiency.

GBC offers high-quality Metric Bore Sprockets in Australia to meet your operational needs.

Specifications for Metric Bore Sprocket for ISO 24B Roller Chain (38.1mm Pitch)

A metric bore sprocket is specifically engineered to function seamlessly within mechanical systems. It serves as a critical component in transferring torque and rotation, connecting a driving shaft to a driven element, often a chain. The bore size of these sprockets is standardized to fit a precise shaft diameter, facilitating easy installation and optimal performance. The Metric Bore Sprocket for ISO 24B Roller Chain is designed to meet these specifications while ensuring reliability and efficiency in power transmission.

Basic Structure and Customization of Sprockets

- Materials: Sprockets can be constructed from various materials such as high carbon steel, alloy steel, or stainless steel, chosen based on the specific requirements of the application.

- Tooth Profile: The design of the tooth profile is pivotal, influencing engagement dynamics and overall performance. Common profiles include standard, double pitch, and specialty configurations tailored for different operational demands.

- Number of Teeth: The quantity of teeth on a sprocket directly affects the speed ratio and torque transmission capabilities, which are vital for effective operation in mechanical systems.

- Dimensions: Sprockets come in various sizes, allowing them to accommodate different chain widths and pitch sizes, ensuring compatibility across various applications.

- Bore: The bore size of a sprocket must match the shaft diameter it is intended to fit, promoting secure and stable connections.

- Keyway: Many sprockets feature keyways, which are essential for maintaining proper alignment and preventing unwanted rotational slippage during operation.

- Su