Metric Bore Sprocket for ISO 28B Roller Chain (44.45mm Pitch)

The Metric Bore Sprocket is designed for use with ISO 606 and DIN 8187 28B roller chains, featuring a precise 44.45mm pitch. This durable sprocket ensures optimal performance and longevity in various applications, making it a reliable choice for your machinery needs. GBC offers high-quality Metric Bore Sprockets in Australia.

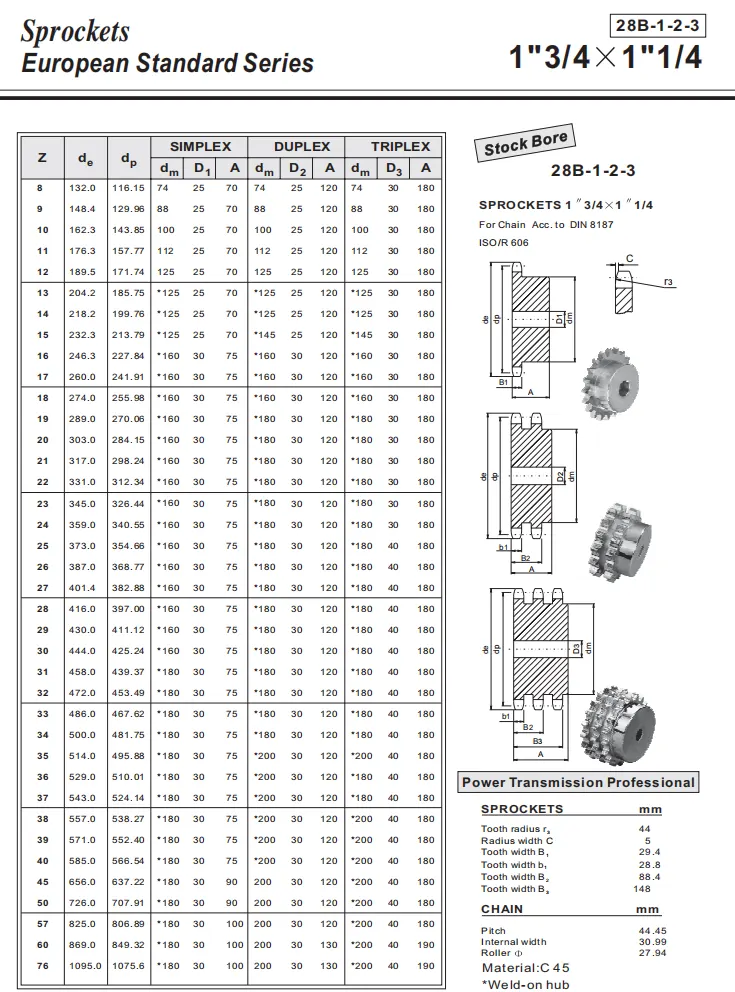

Specifications of Metric Bore Sprocket for ISO 28B Roller Chain (44.45mm Pitch)

A metric bore sprocket is a crucial mechanical device that facilitates the transfer of rotational force between components through a chain. This type of sprocket plays a vital role in numerous industrial machines and applications. The metric bore sprocket is specifically designed with a standard bore size that aligns with a designated metric shaft size. The Metric Bore Sprocket for ISO 28B Roller Chain features 28 teeth, a 44.45mm pitch, and a bore size that is ideal for various operational needs.

Basic Structure of Sprocket

The primary components of a sprocket include its teeth, bore size, pitch, and keyway. The teeth interlock with the chain to effectively transfer power while ensuring that the chain remains securely in place to prevent slipping. When customizing a sprocket, important features such as material, tooth profile, teeth count, dimensions, bore size, keyway, and surface treatment must be carefully considered to meet specific application requirements. Each aspect contributes to the overall effectiveness and efficiency of the sprocket in its intended use.

Material and Manufacturing Process

The Metric Bore Sprocket for ISO 28B Roller Chain is typically constructed from high-carbon or alloy steel, or stainless steel, which provides the necessary strength and durability. The manufacturing process encompasses several stages, including material selection, cutting, punching, forging, machining, heat treatment, surface hardening, rust prevention, and rigorous quality control measures to ensure the final product meets industry standards.

- Material Selection: High-quality steel is selected for its superior durability and resistance to wear.

- Cutting: The raw material is accurately cut to the required dimensions for subsequent processes