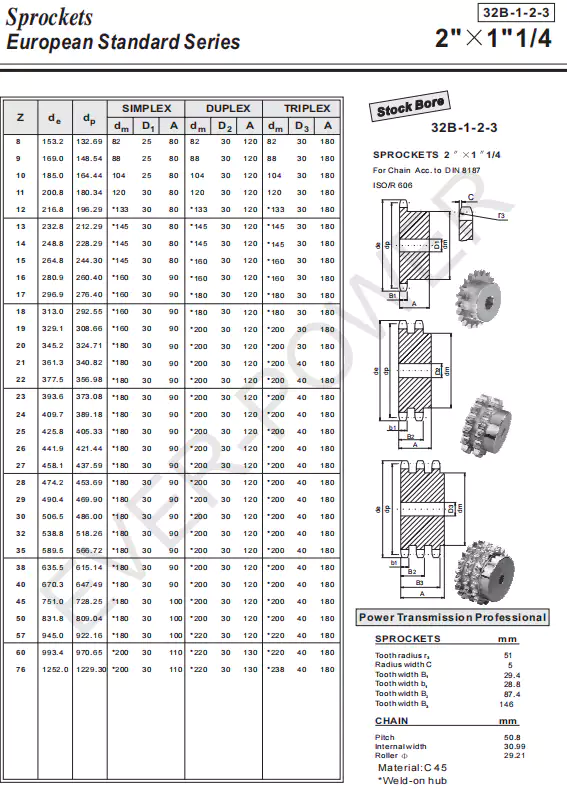

Metric Bore Sprocket for ISO 32B Roller Chain (50.8mm Pitch)

The Metric Bore Sprocket is designed specifically for use with ISO 606 and DIN 8187 32B roller chains, featuring a pitch of 50.8mm. This sprocket ensures optimal performance and durability in various applications, making it an essential component for reliable machinery operation.

GBC proudly offers high-quality Metric Bore Sprockets in Australia, ensuring exceptional performance and longevity for our customers.

Specifications - Metric Bore Sprocket for ISO 32B Roller Chain (50.8mm Pitch)

A metric bore sprocket is specifically designed to accommodate ISO 32B roller chains, which feature a pitch of 50.8mm. These sprockets play a critical role in various industrial settings, effectively transmitting rotary motion between shafts. With a design that includes precisely engineered teeth, they mesh seamlessly with the corresponding chain, ensuring reliable and efficient power transfer across the system.

Basic Structure of a Sprocket

- Material: The choice of material for the sprocket is essential and varies based on application requirements. High carbon steel, alloy steel, and stainless steel are commonly utilized, each offering unique advantages in terms of strength and durability.

- Tooth profile: The tooth profile of a sprocket is a key factor in determining its effectiveness with the chain. Different profiles are optimized for specific chain types to ensure the best engagement and power transmission.

- Number of teeth: The total number of teeth on the sprocket significantly influences the speed ratio and the torque transmission capabilities of the system, which can affect the overall performance of the machinery.

- Size: The physical dimensions of the sprocket must be compatible with the equipment it is intended for. Proper sizing ensures that the sprocket operates within the desired parameters of the application.

- Bore: The bore refers to the central hole that fits onto the shaft. Accurate sizing is crucial for a secure attachment, preventing slippage during operation.

- Keyway: A