Plain Bore Sprocket NK40B (12.7mm Pitch)

The Plain Bore Sprocket NK40B is designed for precision and durability, featuring a 12.7mm pitch that ensures optimal performance in various applications. Made from high-grade materials, this sprocket offers reliable power transmission and longevity. GBC proudly provides high-quality Plain Bore Sprockets in Australia to meet your needs.

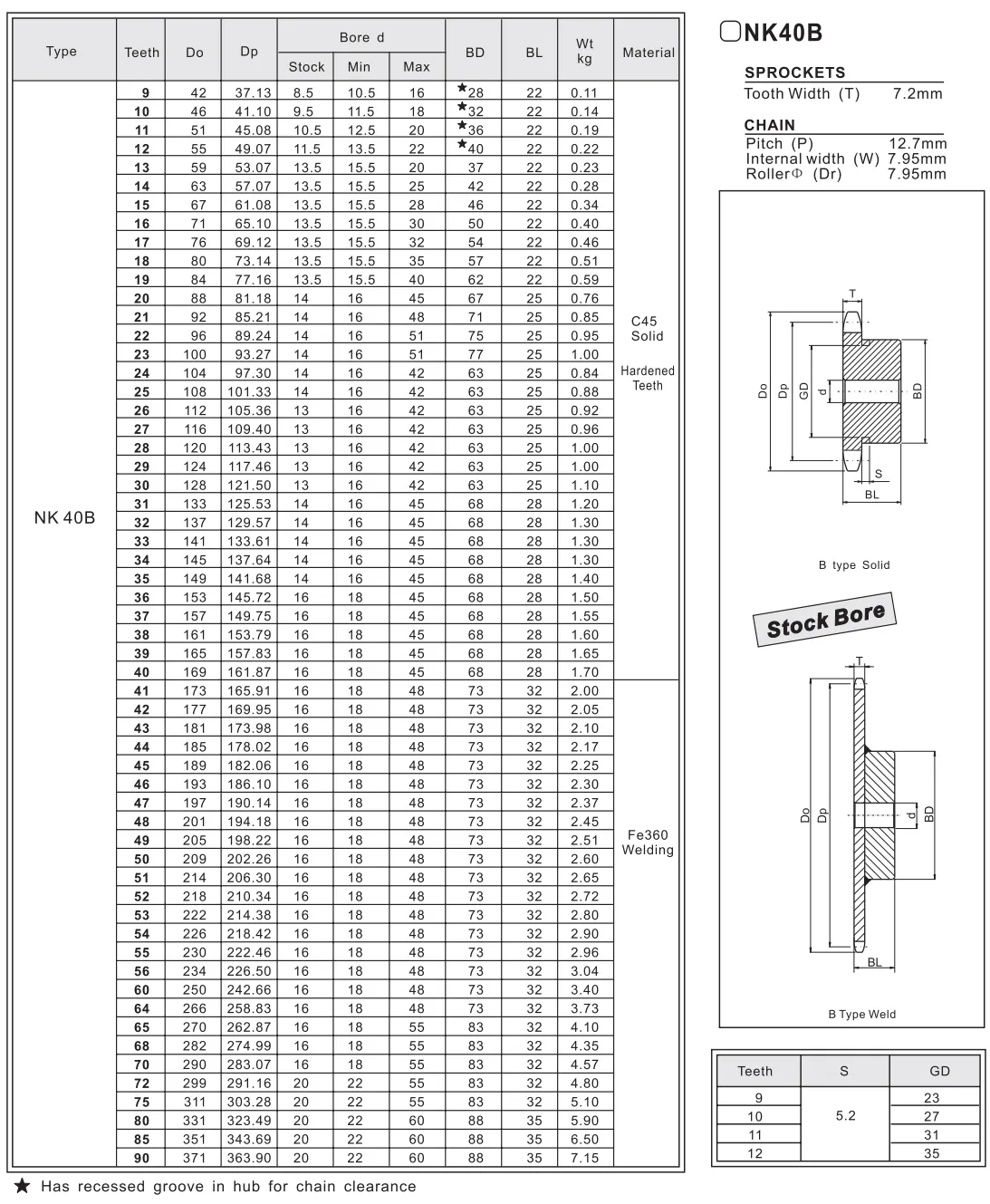

Specifications of Plain Bore Sprocket NK40B (12.7mm Pitch)

A plain bore sprocket is a type of sprocket characterized by a smooth bore without a keyway or set screws. This design allows for easy mounting onto a shaft without the need for additional machining or alterations. The NK40B model, specifically, features a pitch diameter of 2.482 inches and a bore size of 0.625 inches. This standard bore configuration is widely used in various mechanical systems, ensuring reliable performance in demanding applications.

Basic Structure of Sprockets

Sprockets are essential components in mechanical systems, featuring a wheel with teeth that interlock with a chain or track. The fundamental structure of a sprocket comprises two main parts: the hub, which is the central section, and the teeth, which are the external projections that engage with the chain. The hub may incorporate a bore suitable for shaft mounting, and sometimes a keyway that allows for the insertion of a key to securely fasten the sprocket to the shaft. When designing a custom sprocket, crucial parameters must be specified, including:

- Material

- Tooth Profile

- Number of Teeth

- Dimensions

- Bore Size

- Keyway

- Surface Treatment

These parameters significantly influence the sprocket's performance, including its durability, strength, and resistance to wear, ensuring that it meets the specific demands of its application.

Material and Manufacturing Process

The NK40B Plain Bore Sprocket is manufactured from premium-quality carbon steel, alloy steel, or stainless steel. The selection of material is critical, as it affects the sprocket's strength, durability, and wear resistance. The manufacturing process is thorough and includes several stages: material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, and surface treatment, followed by rust pre