Plain Bore Sprocket NK50B (15.875mm Pitch)

The Plain Bore Sprocket NK50B features a 15.875mm pitch, designed for precision and durability in various applications. Constructed from high-quality materials, it ensures optimal performance and longevity. GBC provides top-quality NK50B sprockets in Australia, meeting industry standards and customer satisfaction.

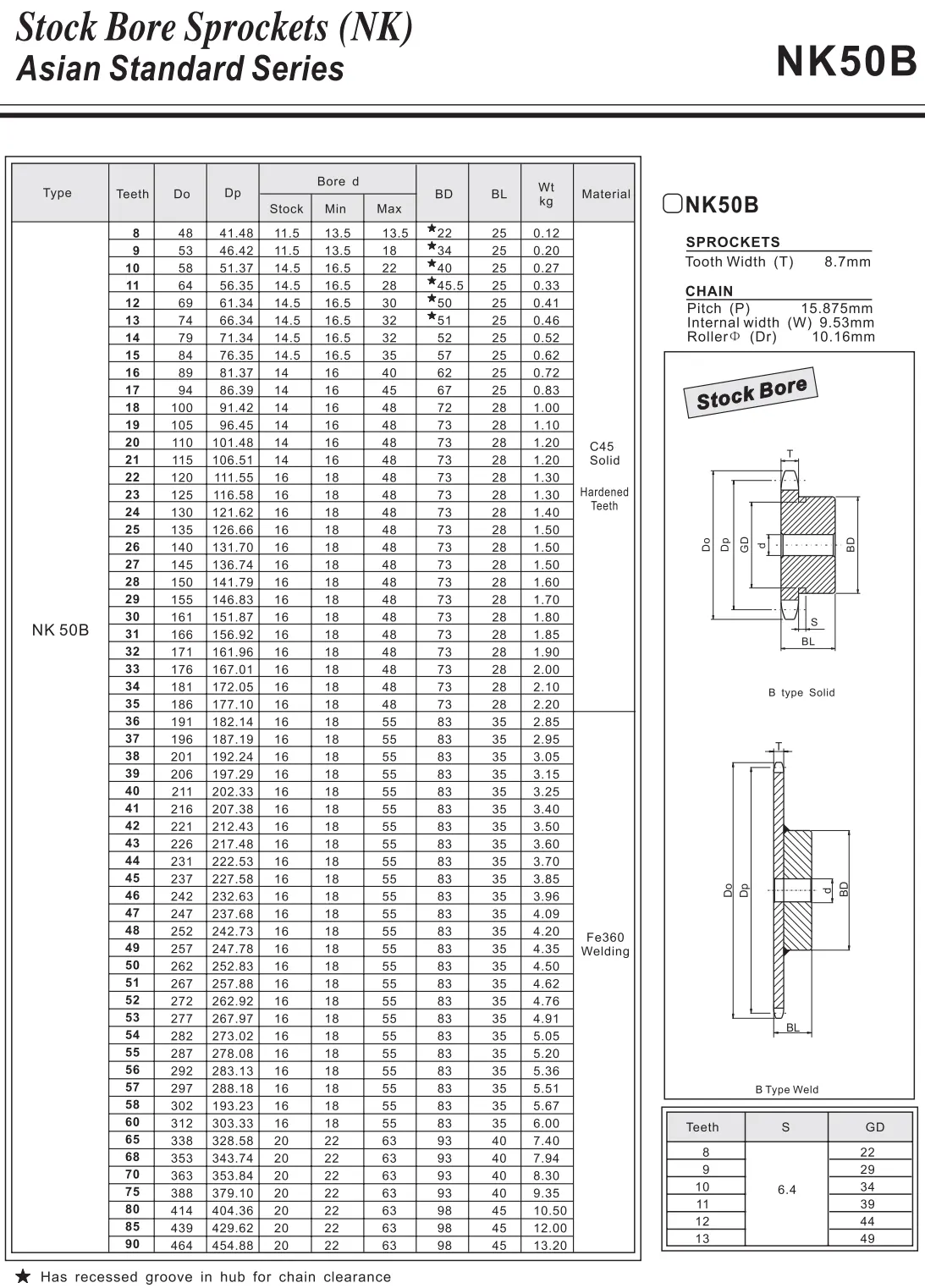

Specifications of Plain Bore Sprocket NK50B (15.875mm Pitch)

A plain bore sprocket is specifically designed with a fixed diameter bore that directly mounts onto a shaft without the need for additional components. This type is essential in power transmission applications where the shaft size is predetermined and follows standardization. The Plain Bore Sprocket NK50B is a notable example, utilized extensively across various industrial sectors for its reliable performance.

Basic Structure of Sprocket and Customization

The fundamental structure of a sprocket comprises a hub and teeth. The teeth interlock with the roller chain links, facilitating rotary motion between the driving and driven shafts. Customization of a sprocket involves careful consideration of several components:

- Material: Sprockets are available in multiple materials, such as high carbon steel, alloy steel, and stainless steel. The selection hinges on specific application needs and environmental demands.

- Tooth Profile: Variations in tooth profiles exist, including standard, non-standard, and special designs for different operational requirements.

- Number of Teeth: This is a critical factor as it influences the speed ratio between the driving and driven shafts, impacting overall efficiency.

- Dimensions: The sprocket's dimensions are determined by chain pitch and tooth count, ensuring compatibility with the chain system.

- Bore Size: Essential for fitting, the bore size must precisely match the shaft diameter for effective operation.

- Keyway: A keyway is incorporated to secure the sprocket onto the shaft, preventing any unwanted rotation during operation.

- Surface Treatment: Surface treatments enhance the sprocket's durability and resistance to corrosion. Common treatments include heat treatment, carburizing, and black oxide coating.