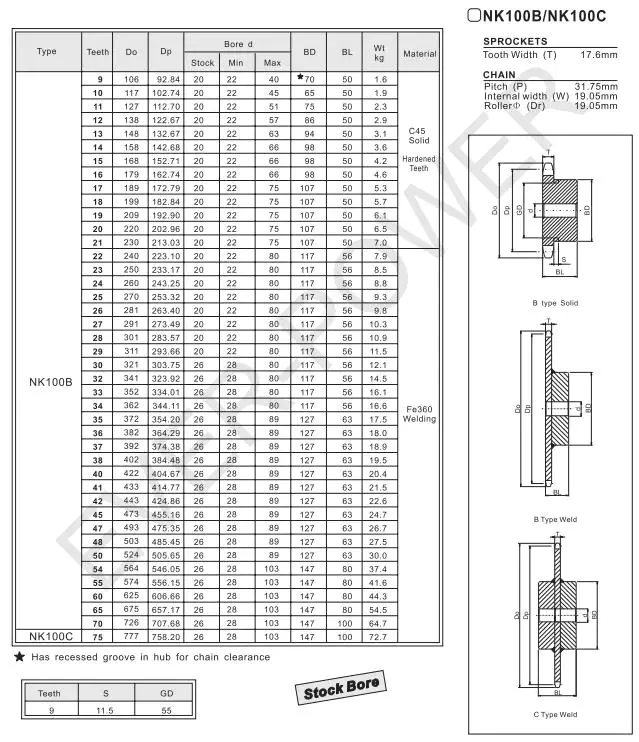

Plain Bore Sprocket NK100B/NK100C (31.75mm Pitch)

The Plain Bore Sprocket NK100B/NK100C features a 31.75mm pitch, designed for durability and performance in various applications. Its robust construction ensures reliable operation, making it an ideal choice for machinery and conveyor systems. GBC proudly supplies high-quality Plain Bore Sprockets in Australia, ensuring customers receive top-notch products.

Specifications of Plain Bore Sprocket NK100B/NK100C (31.75mm Pitch)

A plain bore sprocket is a specific type of sprocket commonly employed in various industrial contexts. Unlike other sprockets that may feature specialized fittings, the plain bore design focuses on a straightforward approach to transmitting rotational motion between shafts using a chain. The design includes teeth that effectively engage the chain, facilitating efficient power transfer and motion execution.

Basic Structure of a Sprocket

- Material: Sprockets are typically crafted from high carbon steel, alloy steel, or stainless steel, tailored to meet distinct application needs.

- Tooth profile: The configuration of the teeth is essential as it influences the interaction between the sprocket and the chain, which is crucial for performance.

- Number of teeth: The count of teeth plays a significant role in determining the gear ratio, which subsequently impacts the speed and torque characteristics of the system.

- Size: The overall dimensions, including diameter and width, are critical in ensuring compatibility with the intended application.

- Bore: The center hole is designed to fit onto the shaft securely, ensuring effective motion transfer.

- Keyway: A slot is often cut into the bore to accommodate a key, which prevents any unwanted rotation of the sprocket on the shaft.

- Surface treatment: Various treatments, such as rust prevention, can be applied to enhance durability and performance, thereby extending the lifespan of the sprocket.

Materials and Processes Used in Sprockets

Our sprockets are manufactured with a commitment to high-quality materials and advanced production techniques. The materials a