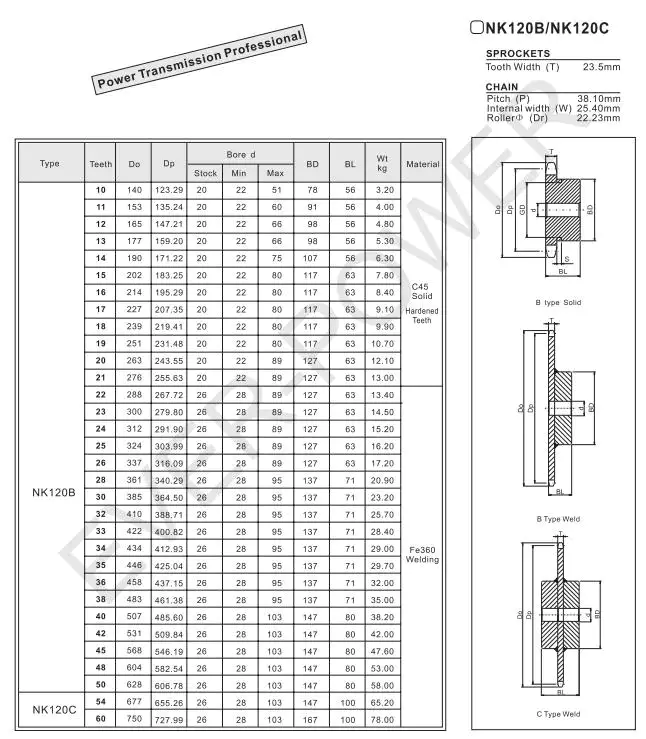

Plain Bore Sprocket NK120B/NK120C (38.1mm Pitch)

The Plain Bore Sprocket NK120B/NK120C features a 38.1mm pitch, designed for optimal performance in various machinery applications. Its robust construction ensures durability and reliability, making it an essential component for efficient power transmission. GBC proudly offers high-quality Plain Bore Sprockets in Australia to meet your industrial needs.

Specifications for Plain Bore Sprocket NK120B/NK120C (38.1mm Pitch)

A plain bore sprocket is a specialized type of sprocket characterized by its fixed center hole size, which is optimized for use in power transmission systems. These sprockets play a crucial role in transferring power between rotating shafts and chains efficiently. The design of the plain bore sprocket allows for a seamless fit onto specific shaft sizes, eliminating the need for any additional modifications or adaptations that could complicate installation.

Basic Structure of a Sprocket

A sprocket comprises several essential components that contribute to its overall functionality:

- Material: The choice of material for the sprocket is critical as it influences the component's strength, durability, and resistance to wear.

- Tooth Profile: The design of the teeth on the sprocket affects how the chain engages with the sprocket, impacting the efficiency of power transfer.

- Number of Teeth: The number of teeth influences both the speed ratio and torque transmission between the driving and driven shafts, making it an important design aspect.

- Size: The dimensions of the sprocket, including diameter and width, are key to ensuring a proper fit within the system.

- Center Bore: The center bore is the central hole that allows the sprocket to be mounted onto the shaft securely.

- Keyway: The keyway is a vital groove that helps prevent the sprocket from rotating independently of the shaft during operation.

- Surface Treatment: Treatments applied to the surface can enhance resistance to rust, corrosion, and wear, extending the lifespan of the sprocket.

Materials and Manufacturing Process

We manufacture our sprockets using high-quality materials such as high-carbon steel, alloy steel, or stainless steel. The selection of material is based on specific application requirements and desired properties, ensuring optimal performance.

The manufacturing process includes several steps to ensure the final