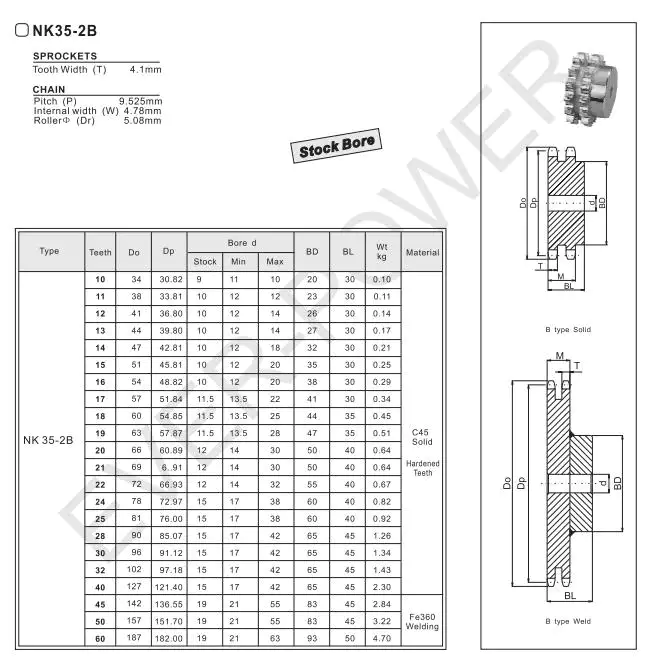

Plain Bore Sprocket NK35-2B (9.525mm Pitch)

The Plain Bore Sprocket NK35-2B features a 9.525mm pitch, designed for optimal performance in various applications. Its robust construction ensures durability and efficiency in power transmission systems. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, meeting the needs of our valued customers.

Specifications for Plain Bore Sprocket NK35-2B (9.525mm Pitch)

The Plain Bore Sprocket NK35-2B (9.525mm Pitch) is a specialized type of chain wheel widely utilized across various sectors. This sprocket plays a crucial role in power transmission, where it facilitates the transfer of motion or energy between two rotating shafts, ensuring efficiency and reliability in mechanical systems.

Basic Structure of a Sprocket

A typical sprocket comprises several essential components, including teeth, a bore, and potentially keyways. When customizing a sprocket, it is vital to consider numerous factors to meet specific operational needs:

- Material: The selected material can vary based on application requirements, with options such as high carbon steel, alloy steel, or stainless steel being popular choices.

- Tooth Profile: The design of the tooth profile significantly influences the effectiveness and engagement of the chain drive system. Various profiles are available, including standard, double pitch, and specialized configurations.

- Number of Teeth: The count of teeth determines both the speed ratio and the torque transmission capacity, making it a critical factor for performance.

- Dimensions: Proper dimensions, including outer diameter and hub diameter, are essential for successful installation and precise alignment with other components.

- Bore Size: The bore size must correspond to the shaft diameter to ensure a secure and accurate fit during installation.

- Keyway: If necessary, integrating a keyway into the sprocket can help prevent any rotational slippage during operation.

- Surface Treatment: Various surface treatments, including heat treatment and rust prevention, are applied to enhance the durability and resistance of the sprocket to environmental factors.

Materials and Processes

The manufacturing of our sprockets involves high-quality materials such as high carbon steel, alloy steel, or stainless steel. The production process encompasses several stages: selecting the right material, cutting, stamping or forging, precise machining, heat treatment, surface hardening, rust prevention, and rigorous quality control to ensure that each sprocket meets industry standards.

Applications

Plain Bore Sprocket NK35-2B finds a variety of applications in numerous industries, including:

- Heavy Machinery and Equipment: Essential for the operation of various machines.

- Food Processing and Packaging: Used in conveyor systems and other machinery.

- Chemical and Pharmaceutical: Critical components in processing and manufacturing equipment.

- Assembly Lines: Integral to the functioning of assembly machinery.

- Logistics and Warehousing: Plays a role in material handling systems.

Maintenance and Care

Appropriate maintenance and care are vital for ensuring the longevity and optimal performance of sprockets. Here are key maintenance tips:

- Daily Inspection: Regular inspections are crucial to identify any signs of wear, damage, or misalignment. This practice helps in early detection of potential issues.

- Cleaning: Keeping the sprocket clean from dirt, debris, and any lubrication residues is essential for preventing wear and ensuring smooth operation.

- Lubrication: Applying the correct lubrication is necessary to reduce friction, enhance performance, and extend the lifespan of the sprocket.

- Adjustment and Calibration: Regularly check and adjust the tension of the chain to ensure proper alignment and functionality of the system.

Common Problems and Solutions:

- Skipping Teeth: Often caused by improper tension or a worn-out chain. Adjust the tension or consider replacing the chain to resolve this issue.

- Breakage: Excessive load or fatigue can lead to sprocket breakage. In such cases, replacing the sprocket is the best solution.

- Wear: Continuous use can cause wear over time. Timely replacement of worn sprockets is essential to maintain performance.

- Noise: Excessive noise could indicate misalignment or insufficient lubrication. Correcting the alignment or applying lubrication as necessary can mitigate this problem.

- Chain Disengagement: Ensure that the chain is seated properly on the sprocket to prevent disengagement. If it does become dislodged, re-engage the chain promptly.

Plain Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we pride ourselves on being one of the best sprocket suppliers in Australia. Our Plain Bore Sprocket NK35-2B (9.525mm Pitch) exemplifies our commitment to quality and precision engineering. Each sprocket is manufactured to the highest standards, ensuring durability and reliability in various applications.

At GBC, we understand the importance of strong customer support, which is why we offer comprehensive pre-sales and after-sales services. Our knowledgeable team is always ready to assist you in choosing the right products for your needs and ensuring your satisfaction throughout the purchasing process.

Moreover, we can accommodate non-standard customizations based on customer requirements, making us a versatile partner for your sprocket needs.

Additional information

| Edited by | Sylvia |

|---|

The Plain Bore Sprocket NK35-2B features a 9.525mm pitch, designed for optimal performance in various applications. Its robust construction ensures durability and efficiency in power transmission systems. GBC is proud to offer high-quality Plain Bore Sprockets in Australia, meeting the needs of our valued customers.