80 Weld on Sprockets and Hubs

The 80 Weld on Sprockets and Hubs are essential components for various mechanical applications, providing reliable connection and smooth operation. These sprockets can be paired with our W, X, and XX series weld-on hubs, ensuring compatibility and enhancing performance for your machinery and projects.

Specifications of 80 Weld on Sprockets and Hubs

| No.Teeth | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 32 | 33 | 34 | 35 | 36 | 40 | 45 | 48 | 54 | 60 | |

| 80 | 1" Pitch | 80W9 | 80W10 | 80W11 | 80X12 | 80X13 | 80X14 | 80X15 | 80X16 | 80X17 | 80X18 | 80X19 | 80X20 | 80X21 | 80X22 | 80X23 | 80X24 | 80X25 | 80X26 | 80X27 | 80X28 | 80X29 | 80X30 | 80X32 | 80X33 | 80X34 | 80X35 | 80X36 | 80X40 | 80X45 | 80X48 | 80X54 | 80X60 |

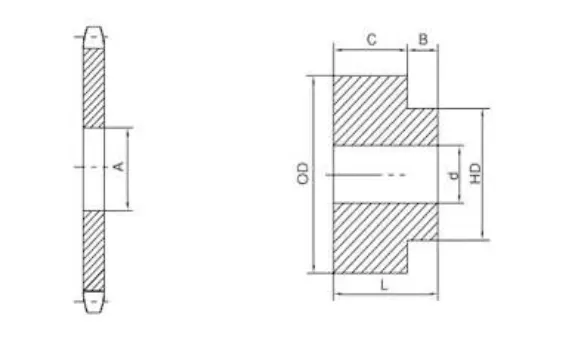

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | Hub No. | A | |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | V | 1-1/8 | |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | W | 1-5/8 | |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | X | 2 | |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | XX | 2 | |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | Y | 2-3/4 |

Applications and Industry Suitability of 80 Weld on Sprockets and Hubs

The 80 Weld on Sprockets and Hubs are essential components in various industrial applications, particularly in material handling, agriculture, and manufacturing. They are designed for use in conveyor systems, agricultural machinery, and robotic systems, where reliable power transmission is critical. Typical use cases include connecting motors to belts in conveyor lines and enabling movement in agricultural equipment like seeders and harvesters. Their robust constru