Gearbox reducer is an indispensable part of industrial equipment, widely used in various mechanical transmission systems. Choosing the right gearbox reducer is essential to ensure the normal operation of equipment, improve efficiency and extend service life.

1. Understanding the Basic Concepts of Gearbox Reducers

1.1 Definition of Gearbox Reducer

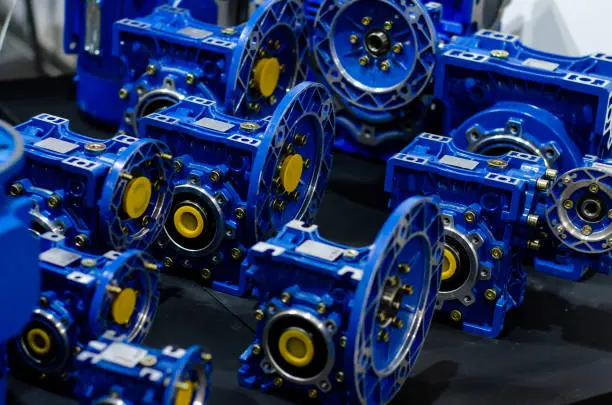

A gearbox reducer is a device that reduces speed and increases torque through gearing. It usually consists of an input shaft, an output shaft, a gear train and a case.

1.2 Main Types of Gearbox Reducer

Planetary gear reducer: compact structure, strong load carrying capacity, suitable for high-precision occasions.

Parallel shaft gear reducer: simple structure, lower cost, suitable for general industrial applications.

Worm gear reducer: large transmission ratio, strong self-locking function, suitable for low-speed and heavy-duty occasions.

2. Determining Application Requirements

2.1 Load type

Constant load: small load variation, e.g. conveyor belts.

Variable load: large load variation, e.g. cranes.

2.2 Speed and torque requirements

Input speed: the speed of the motor or other power source.

Output speed: the speed required by the equipment.

Torque: the torque required by the equipment.

2.3 Working environment

Temperature: High or low temperature environment.

Humidity: humid or dry environment.

Corrosiveness: Whether there is corrosive gas or liquid.

3. Selecting a Suitable Gearbox Reducer

3.1 Determining the reduction ratio

The reduction ratio is the ratio of the input speed to the output speed. Select the appropriate reduction ratio according to the required speed and torque of the equipment.

3.2 Selection of gear type

Select the appropriate gear type according to the type of load and working environment. For example, a planetary gear reducer is suitable for high-precision occasions, and a worm gear reducer is suitable for low-speed and heavy-duty occasions.

3.3 Consider the installation method

Horizontal installation: suitable for most occasions.

Vertical mounting: suitable for occasions with limited space.

3.4 Determine the size and weight

Select the appropriate size and weight according to the installation space and load capacity of the equipment.

3.5 Consider maintenance and life

Select a gearbox reducer that is easy to maintain and has a long life to reduce maintenance costs and downtime.

4 Evaluating Suppliers and Brands

4.1 Supplier reputation

Select suppliers with good reputation and word-of-mouth to ensure product quality and after-sales service.

4.2 Brand selection

Choose gearbox reducer of famous brand, usually with more guaranteed quality.

4.3 Price and cost-effective

Under the premise of meeting the demand, choose the products with high cost performance.

5 Installation and commissioning

5.1 Preparation before installation

Check whether the model and specification of the gearbox reducer meet the requirements.

Prepare necessary tools and materials.

5.2 Installation process

Install the gearbox reducer according to the instruction manual to ensure that the parts are firmly connected.

Adjust the gear gap to ensure smooth transmission.

5.3 Commissioning and Testing

Carry out no-load and load tests to check the operation.

Adjust the parameters to ensure the normal operation of the equipment.

6 Maintenance and servicing

6.1 Regular inspection

Check the operation of the gearbox reducer and find and deal with problems in time.

Check the quality and oil level of the lubricant, replace and replenish it in time.

6.2 Cleaning and lubrication

Clean the gearbox reducer regularly to prevent dust and impurities from entering.

Lubricate regularly to reduce wear and friction.

6.3 Replacement of wearing parts

Regularly replace wearing parts, such as seals, bearings, etc., to prolong service life.

Gearbox Reducer Supplier-GBC

Choosing the right gearbox reducer requires a combination of factors such as application requirements, gear type, mounting method, supplier reputation, etc. GBC is a reputable supplier in the field of gearboxes and driveline systems, which has gained the trust of customers all over the world with its high-quality products and professional services. The company focuses on providing customised solutions that meet the diverse needs of different industries and application scenarios. Whether for industrial automation, food processing, logistics or heavy machinery construction, GBC offers efficient and reliable gearboxes.

The strength of GBC lies not only in its extensive product line of planetary gearboxes, parallel shaft gearboxes and worm gearboxes, but also in its strong technical support and comprehensive after-sales service. The company has an experienced team of technicians who are able to support customers in the entire process, from selection and design to installation and commissioning. In addition, GBC focuses on product quality and performance, and all of its products are rigorously tested to ensure stable operation in harsh working environments.

By choosing GBC as a partner, you not only get high quality gearbox products, but also enjoy professional technical service and long-term after-sales guarantee, which is the ideal choice in the field of industrial transmission. Contact us now for a quotation!