Essential Requirements for Heavy-duty Uses

The particular requirements of the application must be determined before choosing a drive chain. High torque, high loads, and challenging operating conditions are typical of heavy-duty applications. Important factors to consider:

- Load capacity: How much weight can the drive chain support at its maximum?

- Operating speed: Does the chain run at a safe pace?

- Operating environment: Are there severe elements like dust, corrosion, or high temperatures?

- Equipment type: What kind of machinery, such as an excavator, crane, or conveyor, will use the drive chain?

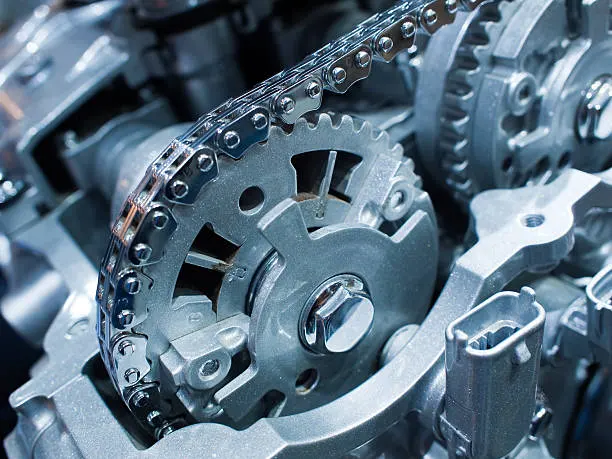

Drive Chain Types and Application Scenarios

There are numerous varieties of drive chains, each with special benefits and uses. Here are some typical drive chain types:

- Roller Chain

The most popular kind of drive chain is the roller chain, which works well for applications requiring modest loads and speeds. Although it is easy and affordable to build, heavy-duty applications could need for more strength and resistance to wear. - Curved Plate Chain

For heavy-duty conveyor systems and lifting equipment, bent plate chain, which is made up of several chain plates and pins, offers exceptional strength and longevity. - Engineering Steel Chain

Engineered steel chains are frequently utilized in mining, metallurgy, and construction because they are made for heavy-duty applications with exceptional strength and fatigue resistance. - Toothed Chain

Powered by teeth meshing, toothed chains are ideal for heavy machinery that has to run smoothly because of their high precision and low noise levels.

Material Selection and Surface Treatment

The material of the drive chain directly affects its performance and life.

- Carbon steel: economical and suitable for general heavy-duty applications, but prone to rust in corrosive environments.

- Alloy Steel: Provides greater strength and wear resistance, suitable for high loads and high speeds.

- Stainless Steel: Highly corrosion resistant and suitable for wet or chemical environments.

- Surface treatment: The wear and corrosion resistance of the chain can be further improved by galvanizing, carburizing or coating treatment.

Chain Size and Strength Calculation

- Pitch: The pitch of the chain determines its load capacity and smooth operation.

- Thickness of chain plate: Thicker chain plate can increase the strength of chain, but it will also increase the weight.

- Tensile strength: Select the chain with sufficient tensile strength according to the maximum load.

- Safety Factor: It is usually recommended to choose a chain with a safety factor of 5-10 to cope with sudden loads.

Supplier Selection and Quality Control

It is vital to choose reliable suppliers and high-quality drive chain products.

- Brand reputation: Choose famous brands to ensure product quality and after-sales service.

- Certification and standards: Ensure the chain meets international standards (e.g. ISO, ANSI or DIN).

- Technical support: Does the supplier provide technical support and customized solutions?

Heavy Duty Conveyor Drive Chain Selection

In the case of heavy-duty conveyors, for example, load, speed and environmental factors need to be taken into account when selecting a drive chain. For example, in a mining environment, engineering steel chains are preferred for their high strength and wear resistance. At the same time, the service life of the chain can be significantly extended by surface treatment and regular lubrication.

Selecting the right drive chain for heavy-duty applications requires a thorough consideration of load, speed, environment, material and maintenance. Efficient operation and long-term reliability of the drive system can be ensured through scientific selection and proper maintenance. In practical applications, it is recommended to work with specialized suppliers and technicians to obtain the best solution.

Drive Chain Suppliers

GBC, as a professional drive chain supplier, offers a large quantity and high quality of chains for various heavy duty applications, our products are of high quality and fast delivery, and we have chain engineers with years of experience to provide professional solutions and after-sales service. Please contact us if you need any further information.