100 Weld on Sprockets and Hubs

The 100 Weld on Sprockets and Hubs are high-quality components designed for seamless integration with our X-type and Y-type weld-on hubs. These sprockets ensure durability and reliability in various applications, providing the perfect solution for your mechanical needs. Experience enhanced performance and efficiency with our expertly crafted products.

Specifications of 100 Weld on Sprockets and Hubs

| No.Teeth | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 28 | 30 | 32 | 35 | 36 | |

| 100 | 1-1/4" Pitch | 100X10 | 100X11 | 100X12 | 100X13 | 100Y14 | 100Y15 | 100Y16 | 100Y17 | 100Y18 | 100Y19 | 100Y20 | 100Y21 | 100Y22 | 100Y23 | 100Y24 | 100Y25 | 100Y26 | 100Y28 | 100Y30 | 100Y32 | 100Y35 | 100Y36 |

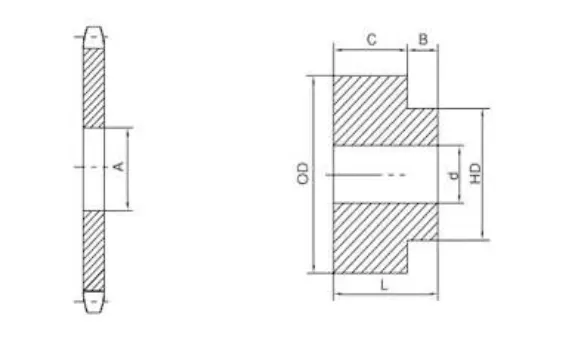

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | Hub No. | A | |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | V | 1-1/8 | |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | W | 1-5/8 | |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | X | 2 | |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | XX | 2 | |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | Y | 2-3/4 |

Applications and Industry Suitability of 100 Weld on Sprockets and Hubs

100 Weld on Sprockets and Hubs are essential components in various mechanical systems, particularly in conveyor systems, agricultural machinery, and automotive applications. These sprockets and hubs provide robust and reliable power transmission, making them ideal for heavy-duty environments. Industries such as manufacturing, agriculture, and logistics frequently utilize these components for their durability and efficiency. For instance, in agricultural equipment, they are used to drive harvesting machinery, while in manufacturing, they facilitate the movement of materials on conveyor belts. Their versatility ensures they meet the demanding needs of different sectors, making them a valuable choice for many applications.

Installation Steps for 100 Weld on Sprockets and Hubs

1. Preparation: Ensure all surfaces are clean and free from contaminants. Check the fit between the sprocket and hub for proper alignment.

2. Preheating: Preheat the components to a temperature between 200¡ãF to 400¡ãF to reduce the risk of cracking during welding.

3. Alignment: Use jigs or fixtures to maintain alignment while welding. This is crucial for optimal performance.

4. Welding Process: Employ a suitable welding technique, ensuring even heat distribution. Use a filler material compatible with the base metals.

5. Cooling: Allow the assembly to cool slowly to minimize residual stresses. Inspect the welds for any defects.

Guide to Using 100 Weld on Sprockets and Hubs

To extend the lifespan of your 100 Weld on Sprockets and Hubs, consider the following maintenance tips:

- Regularly inspect for signs of wear and tear, ensuring all components are securely welded.

- Keep the sprockets lubricated to reduce friction and prevent overheating.

- Check alignment with the chain to avoid unnecessary stress.

- Replace worn chains promptly to prevent damage to the sprockets and hubs.

Weld on Chain Sprockets Supplier

GBC is the Australian sales agent for Ever-power Group, and we are one of the top ten sprocket suppliers in Australia. Our extensive product range includes over 100 weld on sprockets and hubs, designed to meet various industrial needs. Each product is manufactured with precision to ensure optimal performance and durability, catering to different applications.

Our company prides itself on delivering exceptional customer service, ensuring that all clients receive personalized support and expert advice to find the right solutions for their projects.

Additional information

| Edited | Sylvia |

|---|

The 100 Weld on Sprockets and Hubs are high-quality components designed for seamless integration with our X-type and Y-type weld-on hubs. These sprockets ensure durability and reliability in various applications, providing the perfect solution for your mechanical needs. Experience enhanced performance and efficiency with our expertly crafted products.