35 Weld on Sprockets and Hubs

The 35 Weld on Sprockets and Hubs are essential components designed for robust machinery applications. These sprockets are engineered for seamless integration with our V-type and W-type weld-on hubs, ensuring reliable performance and durability. Ideal for various industrial uses, they provide strong connections and effective power transmission in your systems.

Specifications of 35 Weld on Sprockets and Hubs

| No.Teeth | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 42 | 43 | 44 | 45 | 48 | 50 | 54 | 60 | 70 | 72 | 80 | 84 | 96 | |

| 35 | 3/8" Pitch | 35V15 | 35V16 | 35V17 | 35V18 | 35V19 | 35V20 | 35V21 | 35W22 | 35W23 | 35W24 | 35W25 | 35W26 | 35W27 | 35W28 | 35W29 | 35W30 | 35W31 | 35W32 | 35W33 | 35W34 | 35W35 | 35W36 | 35W37 | 35W38 | 35W39 | 35W40 | 35W42 | 35W43 | 35W44 | 35W45 | 35W48 | 35W50 | 35W54 | 35W60 | 35W70 | 35W72 | 35W80 | 35W84 | 35W96 |

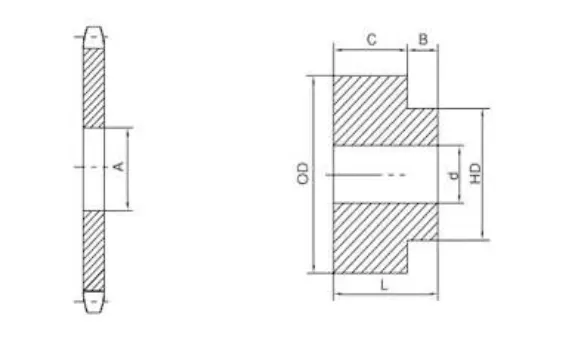

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | Hub No. | A | |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | V | 1-1/8 | |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | W | 1-5/8 | |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | X | 2 | |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | XX | 2 | |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | Y | 2-3/4 |

Versatile Applications of 35 Weld on Sprockets and Hubs in Various Industries

The 35 Weld on Sprockets and Hubs are widely utilized in industries such as agriculture, manufacturing, and construction. They are ideal for connecting drive systems in machinery like conveyor belts, agricultural equipment, and heavy-duty vehicles. Their robust design allows for efficient power transmission and durability in harsh environments. Typical use cases include agricultural harvesters where reliable performance is critical, and manufacturing conveyors that require consistent motion. These sprockets and hubs cater to users seeking reliability and strength in their mechanical systems, making them a suitable choice for various applications.

Installation Steps for 35 Weld on Sprockets and Hubs

When installing 35 Weld on Sprockets and Hubs, follow these steps to ensure a successful weld:

- Preparation: Clean the surfaces of both the sprocket and hub to remove any rust, grease, or debris.

- Preheating: Preheat the components to about 200¡ãF (93¡ãC) to minimize cracking during welding.

- Alignment: Align the sprocket and hub precisely, using clamps to hold them in place.

- Welding: Use a suitable welding technique, such as MIG or TIG, ensuring even penetration.

- Cooling: Allow the welded assembly to cool slowly to avoid thermal stress.

Guide to Using 35 Weld on Sprockets and Hubs

To ensure the longevity and optimal performance of your 35 Weld on Sprockets and Hubs, consider the following maintenance tips:

- Regularly inspect the sprockets for signs of wear, such as uneven teeth or cracks.

- Keep the sprockets clean and free of debris to prevent premature wear.

- Lubricate the hubs appropriately to reduce friction and improve efficiency.

- Check alignment and tension of the chain to avoid excessive strain on the sprockets.

Weld on Chain Sprockets Supplier

GBC is the Australian sales agent for Ever-power Group, and we are one of the top ten sprocket suppliers in Australia. Our extensive product range includes 35 types of Weld on Sprockets and Hubs, designed to meet various industrial needs. These high-quality sprockets ensure optimal performance and durability in your machinery.

At GBC, we pride ourselves on providing exceptional customer service, offering expert advice and support to help you find the right solutions for your applications.

Additional information

| Edited | Sylvia |

|---|

The 35 Weld on Sprockets and Hubs are essential components designed for robust machinery applications. These sprockets are engineered for seamless integration with our V-type and W-type weld-on hubs, ensuring reliable performance and durability. Ideal for various industrial uses, they provide strong connections and effective power transmission in your systems.