41BS* American Standard Finished Bore Sprocket

The 41BS* American Standard Finished Bore Sprocket is engineered for durability and precision, designed to deliver reliable performance in various applications. Constructed from high-quality materials, this sprocket ensures optimal power transmission and minimizes wear and tear over time. Its finished bore design allows for easy installation on drive shafts, making it a practical choice for both new installations and replacements. GBC proudly offers this product throughout Australia, ensuring you have access to top-notch industrial components.

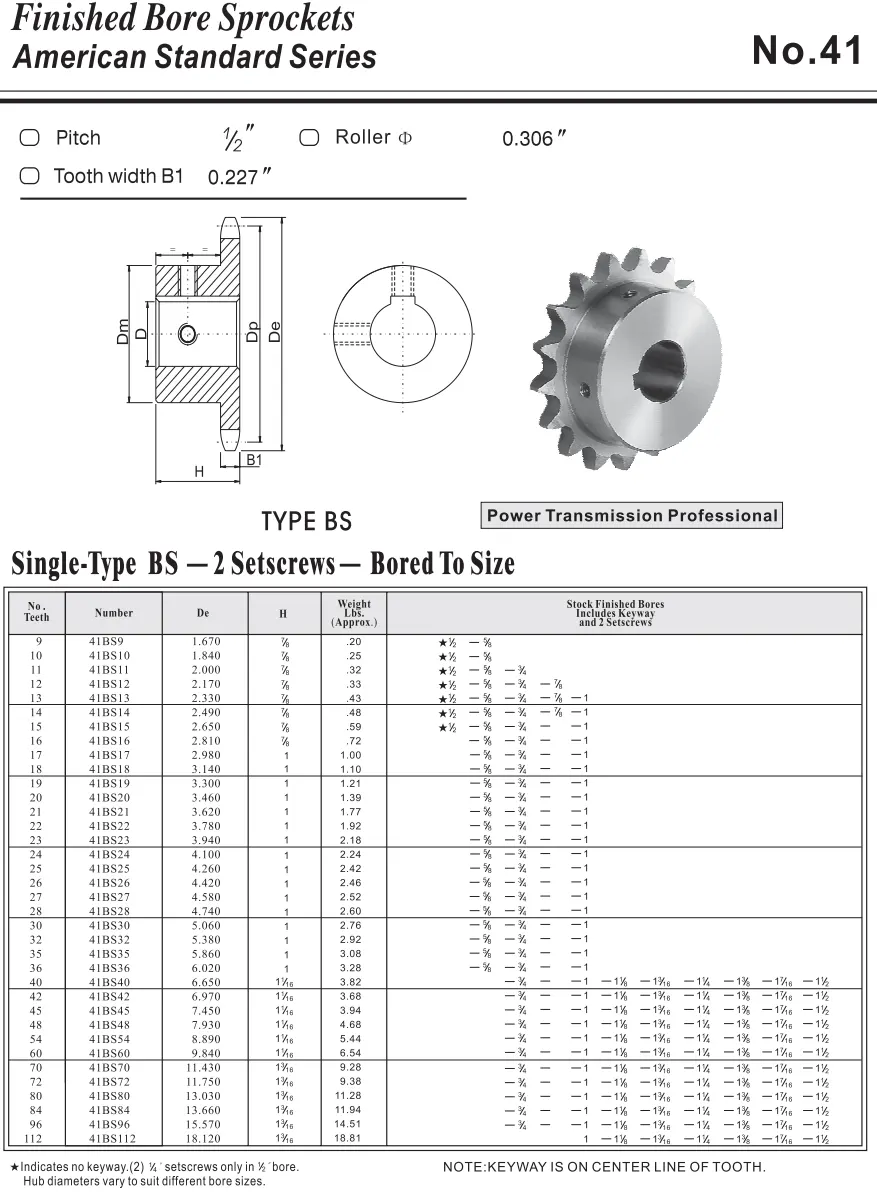

Specifications of 41BS* American Standard Finished Bore Sprocket

Finished bore sprockets find extensive use across various industries and applications. These sprockets are pre-machined to accommodate specific shaft sizes and include a keyway. The 41BS* American Standard finished bore sprocket is favored for its reliability and durability.

Material and Manufacturing Process

- Materials: The 41BS* American Standard finished bore sprocket can be constructed from high carbon steel, alloy steel, or stainless steel. These materials are selected for their robust strength, longevity, and resistance to wear and tear.

- Manufacturing Process: The manufacturing process encompasses material selection, cutting, stamping, forging, machining, heat treatment (quenching and tempering), surface hardening, surface treatment (anti-rust coating), and quality inspection. Each phase is meticulously executed to guarantee the sprocket's precision, strength, and durability.

Maintenance and Troubleshooting

Effective maintenance is crucial for extending the lifespan of a plate wheel sprocket. Daily inspections, cleaning, lubrication, adjustment, and calibration are vital to maintain the sprocket in optimal condition. Common issues that may arise include tooth skipping, breakage, wear, noise, and chain slippage. Below are some solutions to these concerns:

- Tooth Skipping: This issue may arise from a worn sprocket or chain. It’s important to replace the worn components promptly.

- Breakage: Breakage can result from material fatigue or overload. If the sprocket is damaged, it should be replaced.

- Wear: Over time, the teeth of the sprocket may wear down. If the teeth become sharp or hook-shaped, replacing the sprocket is necessary.

- Noise: Noise may be caused by factors like misalignment, worn sprocket teeth, or insufficient lubrication. It’s advisable to check for these issues and make the necessary adjustments.

- Chain Slippage: This may occur due to worn sprocket teeth, inadequate tension, or a damaged chain. Replace any worn or damaged components and adjust the tension as needed.

Other Products

Alongside the 41BS* American Standard finished bore sprocket, GBC - Ever-power Australia Agency also provides various other types of sprockets, including taper lock sprockets, QD sprockets, idler sprockets, and a diverse range of chains.

Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group, providing high-quality power transmission products to the local market. One of our standout products is the 41BS* American Standard Finished Bore Sprocket. This sprocket is designed for durability and efficiency, making it ideal for various applications in machinery and equipment. Our products undergo rigorous quality checks to ensure they meet industry standards, giving our clients peace of mind.

In addition to standard sprockets, we also offer custom solutions tailored to meet specific customer requirements. We welcome clients to bring their drawings or samples for non-standard customizations. Our team is dedicated to providing exceptional service and products that cater to your unique needs.

Additional information

| Edited by | Sylvia |

|---|

The 41BS* American Standard Finished Bore Sprocket is engineered for durability and precision, designed to deliver reliable performance in various applications. Constructed from high-quality materials, this sprocket ensures optimal power transmission and minimizes wear and tear over time. Its finished bore design allows for easy installation on drive shafts, making it a practical choice for both new installations and replacements. GBC proudly offers this product throughout Australia, ensuring you have access to top-notch industrial components.