#60 Chain Idler Sprocket

The #60 Chain Idler Sprocket is a crucial component in roller chain systems, designed to guide and support the chain during operation. It helps maintain proper tension and alignment, reducing wear and tear on the chain and extending the overall lifespan of the system. This idler sprocket ensures smooth and efficient performance in various machinery applications.

Specifications of #60 Chain Idler Sprocket

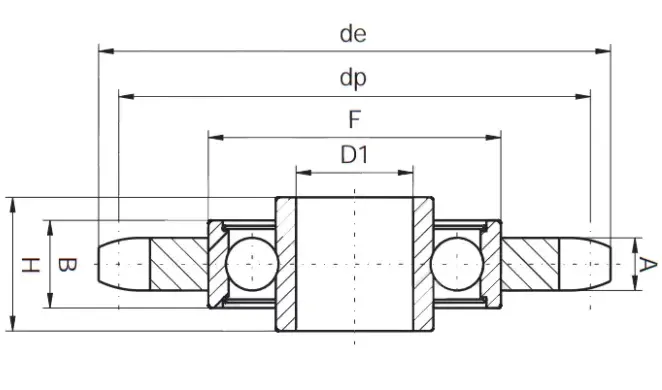

Ball Bearing Idler Sprocket

| Z | Pitch | de | dp | A | D1 | F | B | H | Chain Size |

| 13 | 3/4"×7/16" | 87.5 | 79.59 | 11.1 | 16 | 40 | 12 | 18.3 | #60 |

| 15 | 3/4"×7/16" | 99.8 | 91.63 | 11.1 | 16 | 40 | 12 | 17.3 | #60 |

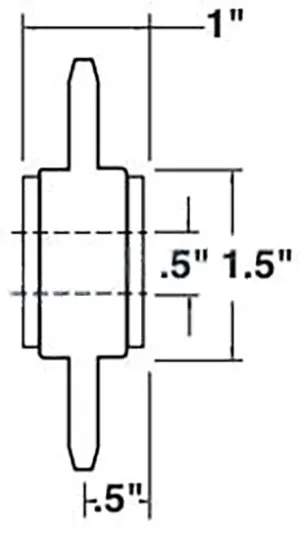

Bronze Bushed Idler Sprocket

| Sprocket Size | Number Of Teeth | Chain Size | Outside Diameter | Bore Size | Weight |

| 61E14 | 14 | 60 | 3.74" | 1/2" | 0.92 LBS |

Application Scenarios of #60 Chain Idler Sprocket

The #60 Chain Idler Sprocket is widely utilized in various machinery and applications:

- Conveyor Systems: It helps in guiding and maintaining chain alignment, ensuring smooth operation.

- Agricultural Equipment: Used in harvesters and tillers to facilitate efficient power transmission.

- Manufacturing Machinery: Essential for chain-driven equipment, improving productivity and reliability.

- Automotive Applications: Supports chain drives in engine components, enhancing performance.

Comparison of Different Idler Sprocket Types

The #60 Chain Idler Sprocket is available with various bearing types, each offering unique benefits. Ball bearings are known for their smooth operation and durability, making them ideal for high-speed applications. Needle bearings, on the other hand, provide a compact design and can handle heavy loads, making them suitable for space-constrained environments. Bronze bearings offer excellent corrosion resistance and are well-suited for harsh conditions, ensuring longevity. Choosing the right bearing type for your #60 Chain Idler Sprocket can significantly impact performance, maintenance needs, and overall efficiency in your machinery.

Idler Sprockets Selection

Choosing the right idler sprockets, such as the #60 Chain Idler Sprocket, involves several key considerations:

- Compatibility: Ensure the sprocket matches your chain size for optimal performance.

- Material: Select durable materials suited for your application to enhance longevity.

- Load Capacity: Assess the weight and load requirements to prevent premature wear.

- Installation: Consider ease of installation and maintenance for efficient operation.

Idler Sprockets Supplier in Australia

GBC is the Australian sales agent for Ever-power Group and is proud to be one of the top ten gear suppliers in Australia. We specialize in providing high-quality idler sprockets, including the #60 Chain Idler Sprocket, which is known for its durability and efficiency in various applications.

Our products are designed to meet the rigorous demands of different industries, ensuring optimal performance and longevity. At GBC, we understand that every customer has unique requirements, which is why we offer non-standard customization options. We are not limited to just standard idler sprockets; we encourage customers to bring their designs and specifications for tailored solutions that perfectly suit their needs.

Additional information

| Edited by | Sylvia |

|---|

The #60 Chain Idler Sprocket is a crucial component in roller chain systems, designed to guide and support the chain during operation. It helps maintain proper tension and alignment, reducing wear and tear on the chain and extending the overall lifespan of the system. This idler sprocket ensures smooth and efficient performance in various machinery applications.