60 Weld on Sprockets and Hubs

The 60 Weld on Sprockets and Hubs are essential components designed for seamless integration with our V, W, X, and XX series weld-on hubs. These high-quality sprockets ensure durability and efficient power transmission, making them ideal for various applications in mechanical systems, enhancing performance and reliability.

Specifications of 60 Weld on Sprockets and Hubs

| No.Teeth | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 42 | 43 | 44 | 45 | 48 | 50 | 54 | 60 | 70 | 72 | 80 | 84 | 96 | |

| 60 | 3/4" Pitch | 60V9 | 60V10 | 60V11 | 60W12 | 60W13 | 60W14 | 60W15 | 60X16 | 60X17 | 60X18 | 60X19 | 60X20 | 60X21 | 60X22 | 60X23 | 60X24 | 60X25 | 60X26 | 60X27 | 60X28 | 60X29 | 60X30 | 60X31 | 60X32 | 60X33 | 60X34 | 60X35 | 60X36 | 60X37 | 60X38 | 60X39 | 60X40 | 60X42 | 60X43 | 60X44 | 60X45 | 60X48 | 60X50 | 60X54 | 60X60 | 60X70 | 60X72 | 60X80 | 60X84 | 60X96 |

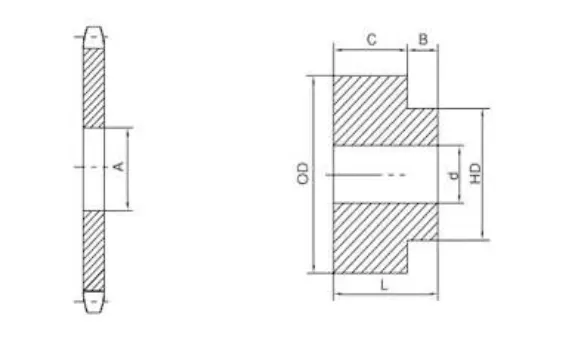

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | Hub No. | A | |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | V | 1-1/8 | |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | W | 1-5/8 | |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | X | 2 | |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | XX | 2 | |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | Y | 2-3/4 |

Applications and Industry Suitability of 60 Weld on Sprockets and Hubs

The 60 Weld on Sprockets and Hubs are essential components in various industrial applications, particularly in sectors such as manufacturing, agriculture, and construction. These sprockets and hubs are ideal for conveying systems, where precise power transmission is required. For instance, they are commonly used in conveyor belts for material handling, enabling efficient movement of goods. Additionally, in agricultural machinery, these components help in driving equipment like harvesters and tillers. Their robust design ensures durability under heavy loads, making them suitable for industries that demand reliability and high performance in their mechanical systems.

Installation Steps for 60 Weld on Sprockets and Hubs

To ensure a successful installation of the 60 Weld on Sprockets and Hubs, follow these steps:

1. **Preparation**: Clean the surfaces to remove any rust, oil, or debris to ensure a strong weld.

2. **Alignment**: Carefully align the sprocket and hub to ensure they are concentric. Use a dial indicator if necessary.

3. **Preheating**: Preheat the components to about 200¡ãF (93¡ãC) to minimize thermal shock during welding.

4. **Welding Process**: Use a suitable welding technique, such as MIG or TIG, ensuring consistent penetration and avoiding excessive heat.

5. **Cooling**: Allow the assembly to cool gradually to avoid warping.

Following these steps will enhance the durability of your welds.

Usage Guide for 60 Weld on Sprockets and Hubs

To ensure the longevity of your 60 Weld on Sprockets and Hubs, consider the following maintenance tips:

- Regularly inspect for signs of wear, such as cracks or deformation.

- Keep the sprockets clean and free from debris to prevent corrosion.

- Lubricate moving parts to reduce friction and prolong lifespan.

- Ensure proper alignment during installation to avoid uneven wear.

- Replace worn sprockets promptly to maintain optimal performance.

Weld on Chain Sprockets Supplier

GBC is the Australian sales agent for Ever-power Group, and we are one of the top ten sprocket suppliers in Australia. Our extensive range includes 60 Weld on Sprockets and Hubs, designed for durability and high performance, catering to various industrial applications. We pride ourselves on offering reliable products that meet the diverse needs of our customers.

Our services include expert advice, quick response times, and a commitment to customer satisfaction, ensuring you receive the best solutions for your sprocket needs.

Additional information

| Edited | Sylvia |

|---|

The 60 Weld on Sprockets and Hubs are essential components designed for seamless integration with our V, W, X, and XX series weld-on hubs. These high-quality sprockets ensure durability and efficient power transmission, making them ideal for various applications in mechanical systems, enhancing performance and reliability.