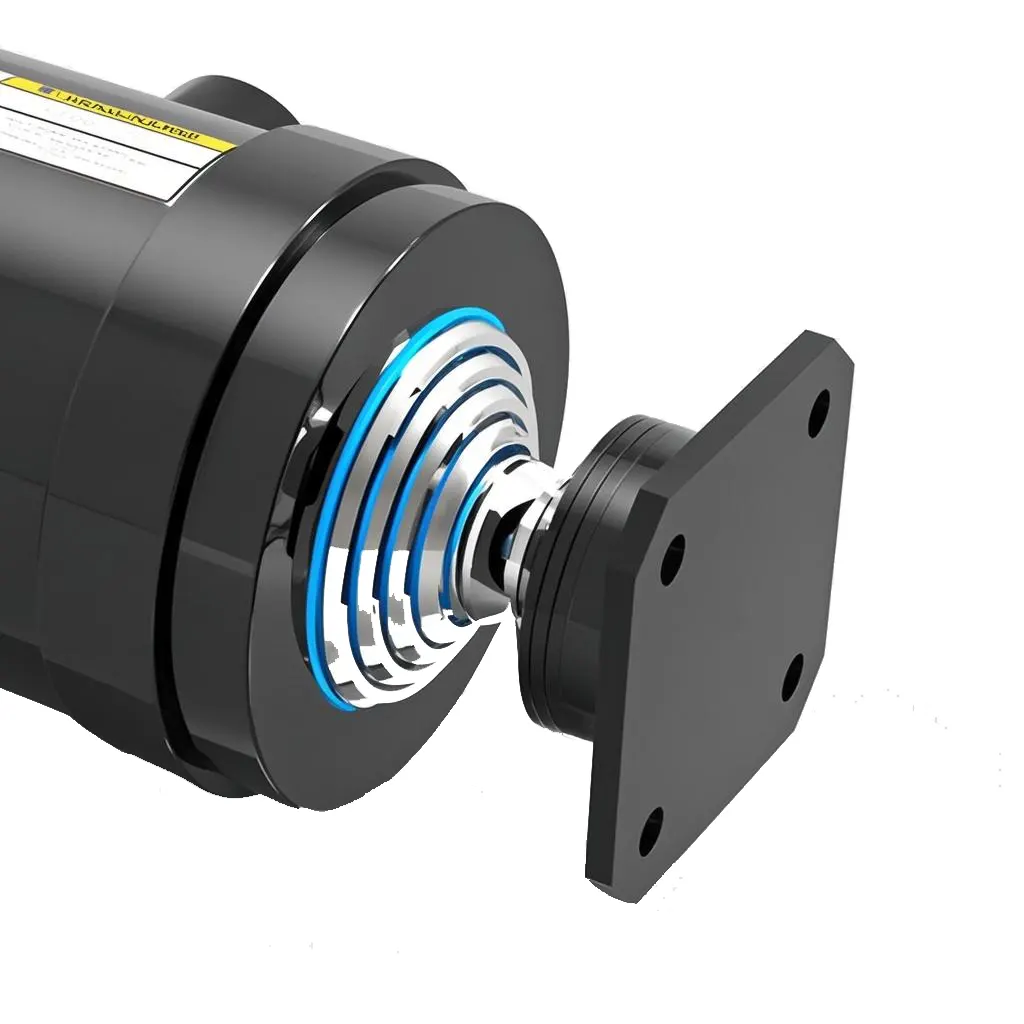

Dump Trailer Telescopic Cylinder

The dump trailer telescopic cylinder is the core component of the lift system for dump trailers and dump trucks and is known for its compact design, long travel and high lift. Whether you need telescopic hydraulic cylinder for dump trailer for construction, mining or agricultural transportation, we have the products to meet your needs. Our range of telescopic cylinders includes a variety of types, such as the 3 stage telescopic hydraulic cylinder for dump trailer, offering superior performance and durability.