|

|

|

| Hydraulic Top Link Cylinder CAT 1 | Hydraulic Top Link Cylinder CAT 2 | Hydraulic Top Link Cylinder CAT 3 |

| Top link hydraulic cylinder CAT 1 is suitable for small to medium tractors with 20-45 HP and 3/4 inch diameter of connection pin. The 3 point hitch hydraulic cylinder offers 150-300 mm travel and is widely used in small and medium-sized farms for cultivation, seeding and other conventional operations, taking into account economy and performance. | For medium tractors ranging from 40 to 100 HP, our top link hydraulic cylinder CAT 2 offers greater load carrying capacity and a travel range of 200 to 400 mm. The connecting pin is 1" in diameter, suitable for medium plow, rake and other farm tools, and is ideal for large-scale agricultural work. | hydraulic top link cylinder CAT 3 is designed for large tractors of 80-225 HP, with a connection pin diameter of 1 1/4 inch and a travel range of 300-600 mm. The tractor top link hydraulic cylinder is suitable for heavy farm tools such as large plows or planters for intensive operations such as deep tillage and land reclamation. |

|

||

| Hydraulic Top Link Cylinder CAT 4 | Hydraulic Top Link Cylinder CAT 0 | |

| For very large tractors (180-400 HP or greater), our hydraulic top link cylinder CAT 4 offers excellent performance. Connecting pins 1 3/4 inches in diameter, travel up to 600 mm or more, suitable for specialized agricultural or engineering work. This 3 point hydraulic cylinder is equipped with locking and floating functions to adapt to complex operating environments. | Hydraulic top link cylinder CAT 0 is designed for miniature tractors (power below 20 HP) and is suitable for small gardening equipment. The compact size of the top link cylinder with a travel range of 100-200mm and a connection pin diameter of 5/8 inch makes it perfect for light duty operations such as small mowing or farming. |

| Category | Top Link Pin Diameter | Lower Link Pin Diameter | Typical Tractor Horsepower Range |

| Category 0 | 5/8 inch (approx. 16 mm) | 5/8 inch (approx. 16 mm) | Less than 20 HP |

| Category 1 | 3/4 inch (approx. 19 mm) | 7/8 inch (approx. 22 mm) | 20 – 45 HP |

| Category 2 | 1 inch (approx. 25 mm) | 1 1/8 inch (approx. 28 mm) | 40 – 100 HP |

| Category 3 | 1 1/4 inch (approx. 32 mm) | 1 7/16 inch (approx. 36 mm) | 80 – 225 HP |

| Category 4 | 1 3/4 inch (approx. 44 mm) | 2 inch (approx. 51 mm) | 180 – 400+ HP |

- Top Link Pin Diameterrefers to the diameter of the pin used to connect the hydraulic top link to the upper hitch point on the tractor.

- Lower Link Pin Diameterrefers to the diameter of the pins at the lower hitch points; it's important for overall system compatibility but doesn't directly affect the top link cylinder.

- Horsepower Rangeis an estimated guideline; depends on the tractor’s specifications for accurate classification.

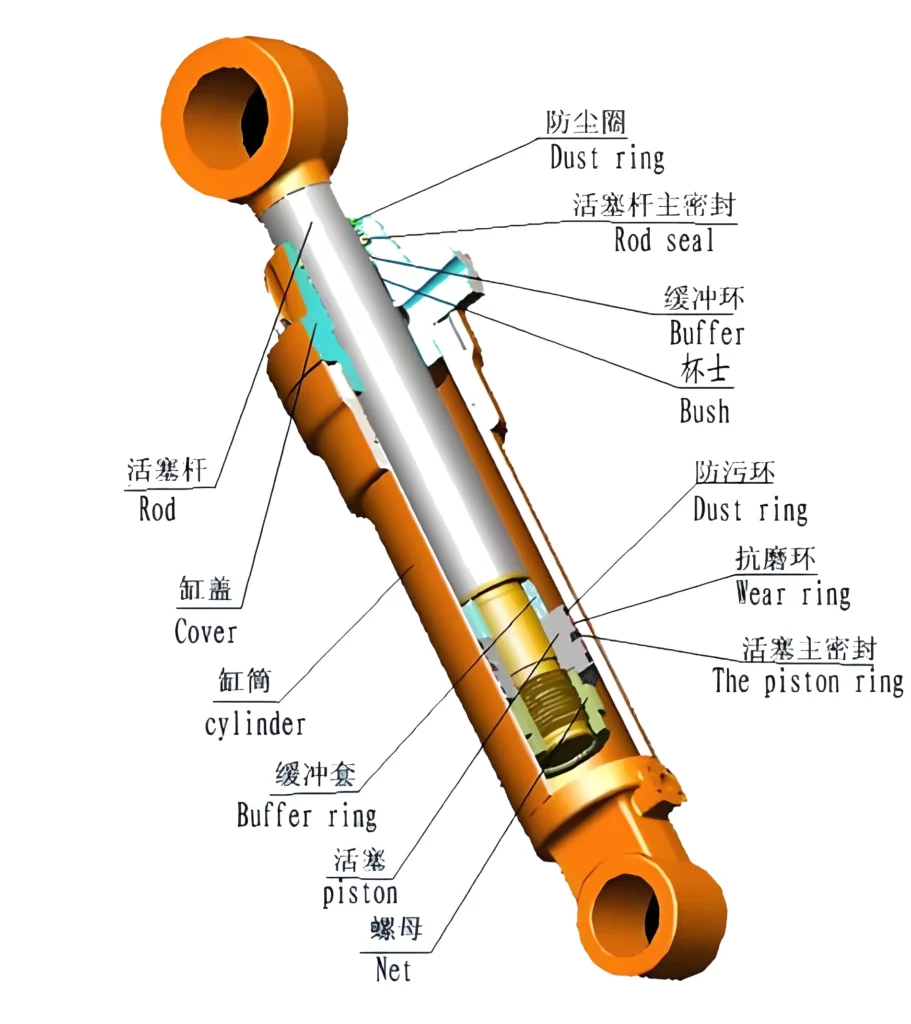

Hydraulic Top Link Cylinder Structure

- Cylinder barrel: High-strength seamless steel pipe, accommodating the piston and hydraulic oil, and withstanding pressure.

- Piston: Slides inside the cylinder barrel, converting hydraulic motion into mechanical motion, and is equipped with a sealing ring.

- Piston rod: Connects the piston, transmits motion, chrome-plated on the surface, wear-resistant and corrosion-resistant.

- Seals: including piston seals, rod seals and dust-proof seals to prevent oil leakage.

- Cylinder head: Seals both ends of the cylinder barrel, including the hydraulic interface, and the front cylinder head supports the piston rod.

- Hydraulic interface: Connects to the hydraulic system of the tractor to control the inflow and outflow of oil.

- Connectors: Ball joints or pin holes (e.g., CAT 1 is 3/4 inches), fixed at three-point suspension.

- Guide ring: Ensures the smooth movement of the piston and piston rod and reduces wear.

How to Choose the Appropriate Hydraulic Top Link Cylinder?

When choosing a hydraulic top-link cylinder, it is necessary to comprehensively consider the model of the tractor, operation requirements, hydraulic system parameters, and the matching situation of farm tools. Our detailed purchasing guide can help you select the most suitable products.

Tractor model compatibility

Ensure that the interface dimensions of the oil cylinder (such as the diameter of the pin shaft and the size of the pin hole) match the three-point suspension system of the tractor. There are significant differences in dimensions among different categories (Categories 1 to 4). Some cylinders support cross-category (such as CAT 1/2), but the compatibility of the connectors still needs to be confirmed.

Hydraulic system matching

The hydraulic top link cylinder must match the flow and pressure parameters of the tractor's hydraulic system. Especially for high categories (such as CAT 3 or 4), higher hydraulic flow and pressure are usually required and are suitable for tractors equipped with high-performance hydraulic pumps.

Operation requirements

Standard type or floating type: Suitable for conventional farm tool operations, commonly seen in CAT 1 and CAT 2.

With locking or quick adjustment function: Suitable for complex operations or farm tools that require frequent adjustments, commonly seen in CAT 3 and CAT 4.

Single/double action selection: Determined by usage frequency and control accuracy. Double-acting cylinders offer stronger control, but they are relatively more expensive.

Stroke and size

The stroke of the hydraulic cylinder should be able to meet the length adjustment requirements of the farm tools under different working postures. High-grade top link cylinders typically offer longer strokes and greater load-bearing capacity, making them suitable for heavy farm tools or wide-range angle adjustments.

Budget factor

Cylinders with simple structures (such as standard single-acting) have lower costs, while those with more complex functions (such as double-acting and locking) are more expensive. The cost-effectiveness should be weighed according to the nature of the operation.

Common Faults of Hydraulic Top Link Cylinder and Their Solutions

| Fault | Causes | Symptoms / Performance | Solutions | Prevention |

| Hydraulic oil leakage | Worn or aged seals (piston, rod, dust-proof) Scratched piston rod Loose hydraulic interface or cylinder connection |

Oil stains on cylinder surface Weak or unstable movement |

Replace worn seals with high-quality ones Smooth or replace scratched rod Tighten or reseal connections |

Regular seal inspection Avoid overpressure |

| Slow or weak movements | Low hydraulic pressure Contaminated oil blocking flow Air in the cylinder |

Slow extension/retraction Inability to bear load |

Check pump and oil level Replace oil and clean system Bleed air from cylinder Check and adjust pressure |

Use correct spec oil (ISO 46/68) Avoid extreme temperatures |

| Cylinder stuck or cannot move | Foreign objects or corrosion causing sticking Faulty hydraulic valve Severely worn internal parts |

No movement or only one-way movement | Disassemble and clean cylinder Replace worn parts like guide rings Clean or replace control valve |

Avoid exposure to mud/dust Lubricate connectors regularly |

| Abnormal noise | Air in the cylinder Poor-quality or insufficient oil Loose or worn connectors |

Squeaking or banging sounds during operation | Bleed air from system Replace poor-quality/aged oil Tighten or replace pins/connectors |

Check cylinder installation stability Avoid overloading |

| Hydraulic oil overheating | Continuous high load operation Poor heat dissipation Aged or unsuitable oil viscosity |

High surface temperature Reduced efficiency |

Improve ventilation/cooling Clean radiator/tank Use appropriate oil and change regularly Adjust system pressure |

Avoid long operation in heat Schedule work to reduce load |

Suggestions for Use and Maintenance of Tractor Top Link Hydraulic Cylinder

- Consult the tractor manual

Clarifying the three-point suspension category of the tractor and the parameters of the hydraulic system is the basis for choosing the cylinder. - Confirm the compatibility of agricultural tools

The type of the agricultural hydraulic cylinder should match the suspension system of the connected farm tool to avoid installation difficulties or unstable use due to size mismatch. - Scheduled maintenance

Especially in high-pressure working environments (such as CAT 3/4), it is necessary to regularly inspect the quality of hydraulic oil, the wear of seals and the connection status of interfaces to ensure the safety of use and the service life of the cylinder.

|

|

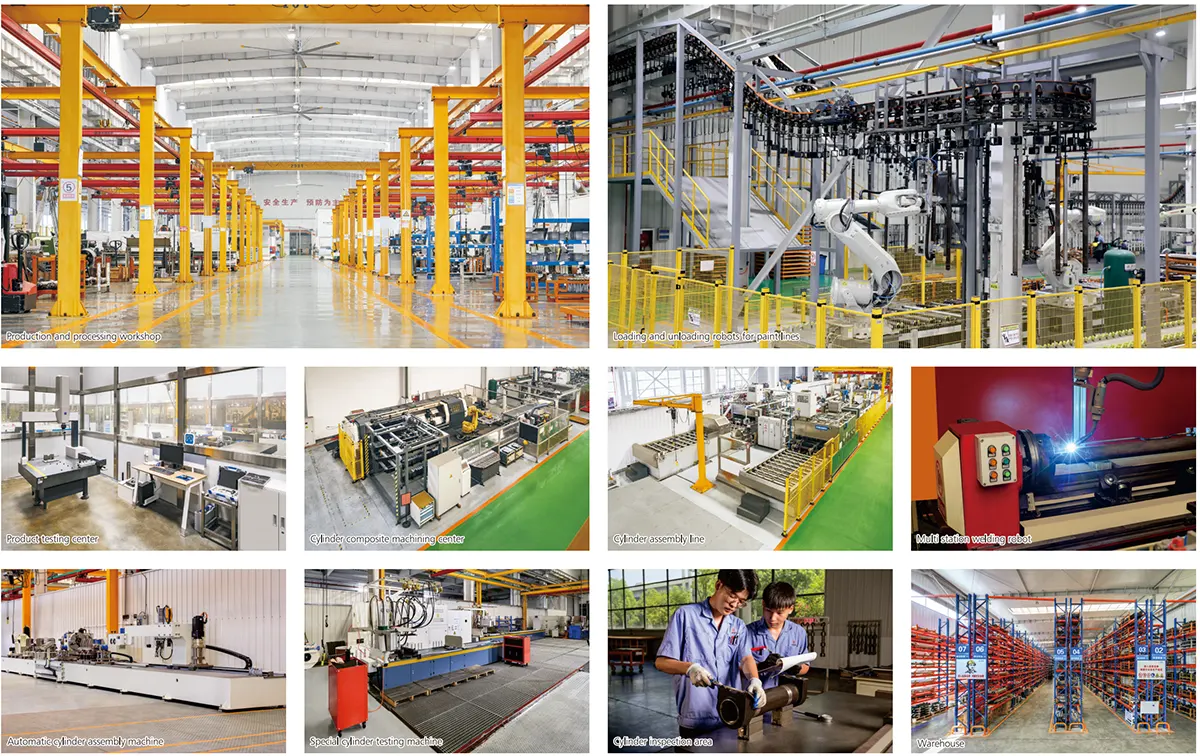

Why Choose Our Hydraulic Top Link Cylinder?

Our top link cylinder is made of high-strength materials, equipped with high-quality seals and corrosion-resistant piston rods to ensure long-term stable performance. Whether it is the single-acting or double-acting design of the 3-point hydraulic cylinder, our products can be seamlessly matched with the hydraulic system of the tractor, providing flexible control and an efficient operating experience.

- Precise adjustment: Through the tractor top link cylinder, the tilt Angle and height of the farm tools can be easily adjusted to adapt to different terrains.

- Durable design: High-strength steel and chrome-plated piston rods, resistant to harsh agricultural environments.

- Multi-category compatibility: Provide various specifications such as hydraulic top link cylinder CAT 1, CAT 2, CAT 3, etc., to meet the requirements of tractors with different powers.

- Easy to install: Standard connector design, compatible with most three-point suspension systems.

Reviews

There are no reviews yet.