Metric Bore Sprocket for ISO 12B Roller Chain (19.05mm Pitch)

The Metric Bore Sprocket is designed for ISO 606 and DIN 8187 12B roller chains with a 19.05mm pitch. This robust sprocket ensures optimal performance and durability in various applications, making it an essential component for efficient power transmission. GBC proudly offers high-quality Metric Bore Sprockets in Australia.

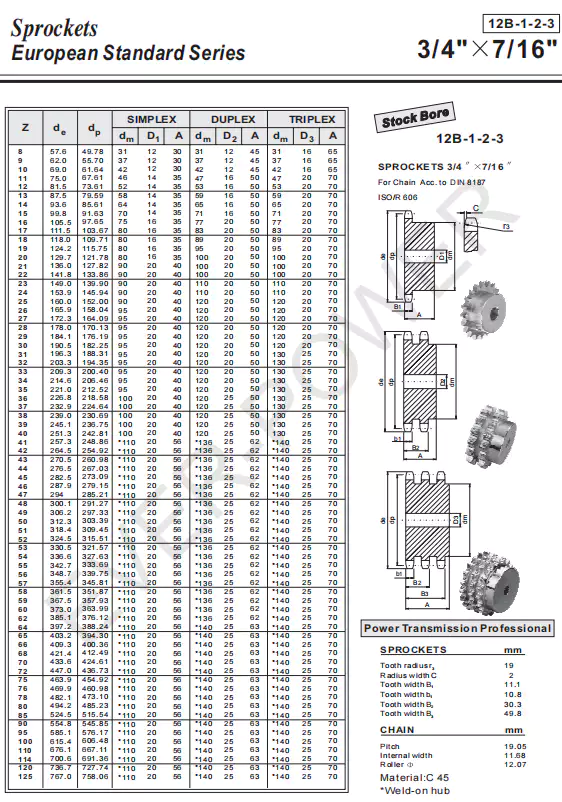

Specifications: Metric Bore Sprocket for ISO 12B Roller Chain (19.05mm Pitch)

A metric bore sprocket is an essential component in power transmission machinery, designed to facilitate efficient power transfer between shafts. The Metric Bore Sprocket for ISO 12B Roller Chain (19.05mm Pitch) is highly regarded in various industries for its robust design and operational efficiency. It features hardened teeth that are engineered to withstand high torque loads, ensuring a long service life and minimal wear over time. Below is a selection table for the Metric Bore Sprocket:

Basic Structure and Customization of Sprockets

A sprocket comprises several key components: a hub, teeth, and a bore. The bore is the central opening that allows the sprocket to fit onto the shaft. Customizing a sprocket involves careful consideration of multiple factors to optimize its performance. These factors include material selection, tooth profile, size, bore dimensions, and surface treatment options.

Material

Sprockets can be constructed from various materials, including high carbon steel, alloy steel, and stainless steel, each having distinct properties suitable for specific applications. High carbon steel is preferred for applications that demand exceptional strength and longevity. Alloy steel offers resistance to both wear and corrosion, making it ideal for challenging environments. In contrast, stainless steel is selected for applications requiring high-temperature and chemical resistance, ensuring durability across diverse conditions.

Tooth Profile and Number of Teeth

The tooth profile and the number of teeth on the sprocket play a crucial role in determining its speed and torque characteristics. The tooth profile may be straight, offset, or curved, influencing how the sprocket engages with the chain. The total number of teeth will dictate the gear ratio, impacting the overall dynamics of the machinery.

Size

The size of the sprocket is defined by its pitch diameter, which is critical for compatibility with the chain's pitch diameter. Ensuring that the sprocket size aligns with the specified chain is vital for the seamless operation of the power transmission system.

Bore and Keyway

Customization of the bore and keyway is necessary to match the specific diameter of the shaft and its corresponding keyway dimensions. This precision is essential for the sprocket's secure fit and effective performance.

Surface Treatment

Surface treatments, such as heat treatment, surface hardening, or corrosion-resistant coatings, are employed to enhance the sprocket's durability. Heat treatment can significantly increase hardness and wear resistance, while surface hardening improves surface durability. Corrosion-resistant coatings help protect the sprocket from rust and other forms of corrosion, which are critical for maintaining performance over time.

Materials and Processes Used in Our Sprockets

Our metric bore sprockets are manufactured from premium materials, including high carbon steel, alloy steel, and stainless steel. We employ a variety of advanced manufacturing processes, ensuring that each sprocket meets rigorous standards for durability and performance.

Material Selection and Cutting

Utilizing advanced computerized systems, we meticulously select the most suitable materials for each sprocket. After selection, the material is cut into the precise shape and size required using CNC machining technology.

Forging and Machining

To enhance strength and durability, the sprocket undergoes a forging process. Following this, precise machining is performed to shape the teeth profile, bore, and keyway, ensuring that all dimensions are accurate.

Heat Treatment

Each sprocket is subjected to heat treatment processes designed to improve hardness and overall wear resistance. This includes quenching in either oil or water to achieve the desired hardness level.

Surface Treatment

We implement various surface coatings to prevent rust and corrosion, utilizing treatments such as black oxide, phosphate, and zinc plating to enhance the sprocket's longevity.

Quality Control

We conduct stringent quality control checks to ensure our sprockets meet the highest standards of durability and performance. Our testing includes hardness, tensile, and impact testing to validate that each sprocket performs reliably in its intended application.

Applications of Metric Bore Sprocket for ISO 12B Roller Chain

The Metric Bore Sprocket for ISO 12B Roller Chain finds extensive use across numerous industries, including:

Heavy Machinery and Equipment Industry

In heavy machinery and equipment, such as cranes, bulldozers, and excavators, these sprockets play a crucial role in ensuring efficient power transmission and operational reliability.

Food Processing and Packaging Industry

This sprocket type is integral to food processing and packaging machinery, including conveyor belts, mixers, and packaging equipment, where precision and reliability are paramount.

Chemical and Pharmaceutical Industry

In the chemical and pharmaceutical sectors, the metric bore sprocket is utilized in processing equipment such as mixers, reactors, and agitators, ensuring optimal operation under stringent conditions.

Assembly Line Industry

This sprocket is critical in assembly line operations, facilitating movement in conveyor systems, rotary tables, and indexing tables to enhance productivity and efficiency.

Logistics and Warehousing Industry

In logistics and warehousing, these sprockets are utilized in conveyor systems, hoists, and lifts, contributing to streamlined operations and improved material handling.

Maintenance and Common Issues of Sprockets

To ensure longevity and optimal performance, proper maintenance of sprockets is crucial. Here are essential maintenance tips and common issues encountered:

Daily Inspection

Conduct daily inspections of the sprocket for any signs of wear, damage, or misalignment. Pay special attention to the teeth for wear patterns or any physical damage that could affect performance.

Cleaning

Regular cleaning of the sprocket is necessary to remove dirt, dust, and debris. Utilizing a wire brush or compressed air can effectively clean the teeth and bore, ensuring smooth operation.

Lubrication

Frequent lubrication is vital to minimize friction and wear. It is recommended to use a high-quality lubricant that suits the specific application to ensure optimal performance.

Adjustment and Calibration

Regular adjustments and calibration are necessary to ensure that the sprocket remains aligned and correctly positioned, which is critical for maintaining operational efficiency.

Common Issues and Solutions

Some common issues that may arise with sprockets include:

Skipping Teeth

Skipping teeth may occur when the sprocket teeth fail to engage properly with the chain. Adjusting the chain tension or replacing the sprocket can resolve this issue.

Breaking or Cracking

High loads or impacts can lead to breaking or cracking of the sprocket. In such cases, replacing the sprocket with a stronger alternative is advisable to ensure continued reliability.

Wear and Tear

Over time, the teeth of the sprocket may experience wear and tear. In these situations, replacing the sprocket or the individual teeth is necessary to maintain functionality.

Noise

Noise can indicate that the sprocket teeth are not engaging smoothly with the chain. Adjusting the chain tension or replacing the sprocket may alleviate the issue.

Chain Slippage

Chain slippage occurs when the chain disengages from the sprocket. Adjusting the chain tension or replacing the sprocket can help rectify this problem.

Metric Bore Sprockets Supplier - GBC

GBC is the sales agent for Ever-power Group in Australia, and we are one of the premier suppliers of sprockets in the region. Our metric bore sprockets for ISO 12B roller chain, featuring a pitch of 19.05mm, are designed with precision to ensure optimal performance and durability. We take pride in our commitment to quality, utilizing top-grade materials and advanced manufacturing processes to produce sprockets that meet the highest industry standards.

At GBC, we understand the importance of excellent customer service. Our dedicated pre-sales and after-sales support ensures that our clients receive the assistance they need from the moment they inquire about our products until their orders are fulfilled. We also offer bespoke solutions, providing non-standard custom sprockets tailored to our clients' specific requirements. With GBC, you can always count on quality and reliability.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket is designed for ISO 606 and DIN 8187 12B roller chains with a 19.05mm pitch. This robust sprocket ensures optimal performance and durability in various applications, making it an essential component for efficient power transmission. GBC proudly offers high-quality Metric Bore Sprockets in Australia.