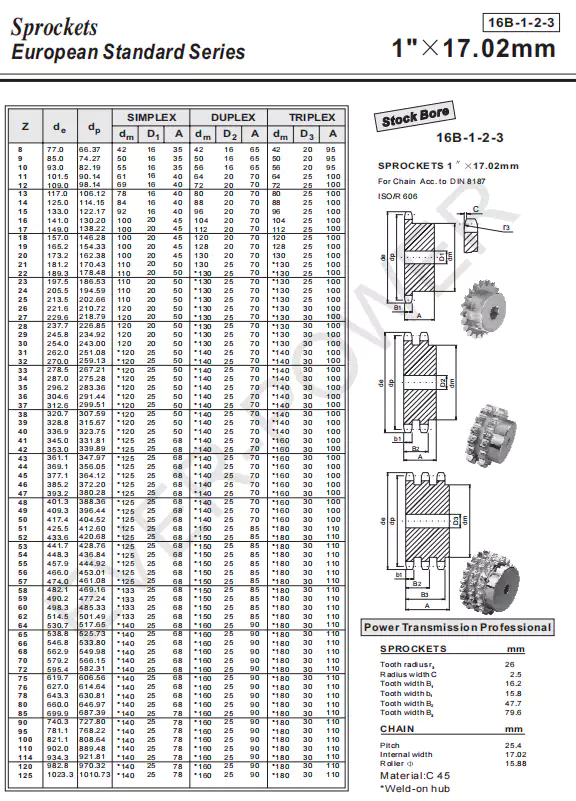

Metric Bore Sprocket for ISO 16B Roller Chain (25.4mm Pitch)

The Metric Bore Sprocket is designed specifically for ISO 606 and DIN 8187 16B roller chains with a 25.4mm pitch. Constructed from durable materials, it ensures optimal performance and longevity in various industrial applications. GBC is proud to offer high-quality Metric Bore Sprockets in Australia, meeting all your operational needs.

Specifications: Metric Bore Sprocket for ISO 16B Roller Chain (25.4mm Pitch)

Selecting a Metric Bore Sprocket for ISO Roller Chain

A standard bore sprocket is a crucial component commonly utilized in diverse industrial applications. It serves the primary purpose of transmitting rotary motion between two shafts through the use of a roller chain. This type of sprocket features a wheel with teeth that interlocks with the chain, facilitating the transfer of power and motion. As a key element in many machinery and equipment systems, its design and functionality are essential for efficient operation. To select an appropriate standard bore sprocket, several important factors should be taken into account:

Material

The material composition of standard bore sprockets can differ significantly depending on the specific requirements of each application. They may be constructed from high carbon steel, alloy steel, or stainless steel, with the right choice influenced by factors like load capacity, expected durability, and environmental conditions. Selecting the correct material is vital to ensure the sprocket can withstand operational demands and provide longevity.

Tooth Profile

The tooth profile plays a significant role in how the sprocket engages with the chain. Common profiles include the standard ANSI tooth profile and the European DIN profile. Choosing the right tooth profile is essential, as it directly impacts the performance and efficiency of the chain-sprocket interaction. Different applications may require specific profiles to optimize performance and minimize wear.

Number of Teeth

The number of teeth on a sprocket is a critical aspect that determines both the speed ratio and torque transmission capabilities. An appropriate selection of teeth based on the desired operational speed and torque requirements is essential for achieving optimal performance. An incorrect number of teeth can lead to inefficiencies and potential mechanical failure.

Dimensions

Dimensions such as outer diameter and width are crucial to ensuring proper chain engagement and alignment. Selecting the right dimensions is important for compatibility with the chain and the overall system, preventing issues such as misalignment or chain slippage that could hinder performance and lead to increased wear.

Center Bore

The center bore is the central hole through which the sprocket is mounted on the shaft. It must be sized accurately to secure a dependable and precise fit. An improperly sized center bore may result in slippage or damage to both the sprocket and the shaft, affecting overall performance.

Keyway

A keyway is a groove on the sprocket that accommodates a key, providing a secure connection between the sprocket and the shaft. It is essential that the size and shape of the keyway align with the key and shaft specifications to ensure a robust coupling that can withstand operational stresses.

Surface Treatment

To enhance the durability and resistance to corrosion of sprockets, various surface treatments can be applied. These treatments may include rust prevention coatings like zinc plating or black oxide processes, alongside heat treatment methods such as quenching and tempering. Proper surface treatment extends the lifespan of the sprocket by protecting it from environmental challenges.

Our Material and Manufacturing Process

GBC - Ever-power Australia Agency manufactures standard bore sprockets using high-quality materials paired with advanced manufacturing processes. Our product offerings encompass high carbon steel, alloy steel, and stainless steel sprockets, tailored to meet specific application demands. The manufacturing process incorporates several stages, including material selection, cutting, punching, forging, machining, heat treatment, surface hardening, rust prevention treatments, and comprehensive quality testing. Each step is meticulously executed to ensure our sprockets achieve the highest quality and performance standards.

Applications

Standard bore sprockets are utilized across various industries and applications, such as:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical sectors

- Assembly lines

- Logistics and warehousing

Maintenance and Care

To maintain optimal performance and prolong the service life of standard bore sprockets, proper maintenance and care are vital. Key practices include:

- Conducting regular inspections to identify signs of wear or damage

- Cleaning to eliminate dirt, debris, and lubrication buildup

- Lubricating to reduce friction and ensure smooth operation

- Adjusting and calibrating to maintain correct chain tension and alignment

Common Problems and Solutions:

1. Skipping teeth: Verify chain tension and alignment. Make adjustments as needed and replace worn sprockets or chains.

2. Breakage: Examine the sprocket for cracks or fractures. Replace it if necessary.

3. Wear: Frequently inspect tooth wear. Replace if it exceeds recommended limits.

4. Excessive noise: Assess for misalignment or insufficient lubrication. Adjust accordingly and ensure proper lubrication is applied.

5. Chain detachment: Check the chain for damaged or bent links. Replace any damaged links and ensure correct tension and alignment.

Metric Bore Sprockets Supplier - GBC

GBC is the Australian sales agent for Ever-power Group, and we take pride in being one of the best sprocket suppliers in Australia. Our Metric Bore Sprockets for ISO 16B Roller Chain (25.4mm Pitch) are designed to meet the highest quality standards, ensuring durability and reliability in every application. We understand the importance of quality and strive to deliver products that exceed our customers' expectations.

In addition to our commitment to quality, GBC offers exceptional pre-sales and after-sales services. Our knowledgeable team is ready to assist you in choosing the right product and providing support after your purchase. Furthermore, we are equipped to handle custom requests, allowing us to manufacture non-standard sprockets tailored to meet your specific requirements.

Additional information

| Edited by | Sylvia |

|---|

The Metric Bore Sprocket is designed specifically for ISO 606 and DIN 8187 16B roller chains with a 25.4mm pitch. Constructed from durable materials, it ensures optimal performance and longevity in various industrial applications. GBC is proud to offer high-quality Metric Bore Sprockets in Australia, meeting all your operational needs.